PVC spray booth systems

group nameautomatic powder coating booth

-

Min Order1 piece

brand nameHICOLO

modelCOLO

payment methodT/T, Western Union, PAYPAL

-

update timeWed, 05 Aug 2015 16:48:26 GMT

Paramtents

coating powder coating

structure Chain Conveyor

material Stainless Steel

type Vibrating Conveyor

line gas tank color coating

Provided available

Automation Automatic

certificaton CE/ISO

Packging & Delivery

Min Order1 piece

Briefing

highest power recovery and fast colour

Detailed

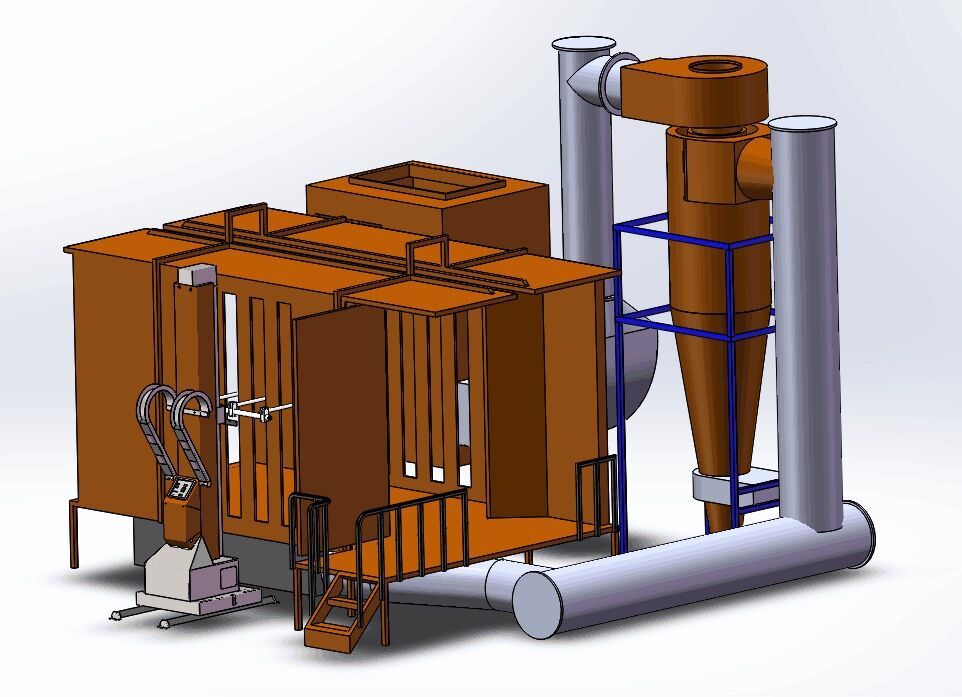

Cyclone fast color change powder spray system

2,Faster Color Change:The Bottom of the Booth prevents accumulation of the powder and makes it very easy for cleaning and quick Color change.

3,Higher life of cartridge filter with unique Rotary wing cleaning mechanism

Spray booth by a plastic sandwich structure of the whole production, play an anti-static, not easily adsorbed powder effect.

Center for the powder spray booth is equipped with a PLC control and cleaning systems, enabling the recovery of powder through vibrating sieve, dirt or large particles caused due to clean-up are separated, cleaned the powder is collected into a center for the powder, saving cleanup reclaimed powder keg of time.

Cyclone size is optimized to ensure a high separation rate of powder, all of the upper single cyclone is actually self-clear, high color change requires a greater or simply blow clean the lower part of the cone bucket can improve cleanup effectiveness. If install automatic reciprocating machine, so can do automation powder coating .

Equipment, key mechanical parts and electrical components using the world's top brand products, to ensure the system is reliable and durable

Booths size could Custom designed,Manual and automatic spray stations are also available. Other features include:Durable, long-life powder-coated steel structure with high-quality galvanized canopy and floorLow-profile booth base eliminates operator platformsRequires only quick, easy connect electrical and pneumatics to start production .Fan motor is 1.5KW-5.5KW.

During Operation overspray powder accumulates on the cartridge filters. As the cartridge filters load, airflow decreases and the negative pressure rises within the air handler. A timer activates a system of air purging valves that clean the cartridge filters of the accumulated powder to ensure maximum flitter life.This Equipment, all kinds of size can be available that the size depending on the size of workpiece and how many workpiece you will spray in a day.

Other product show

We have many years experiences on powder coating. We are a typical Chinese supplier and specialized in the research, development and production of powder spray booths, powder coating oven,powder coating gun,powder coating line. We insist in offering superior quality products and efficient service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, PayPal, Westem Union

- Export mode

- Have the independent export and import right