Scroll Coil Cutting Line

group nameTinplate & Aluminum Scroll Cutting Line

-

Min Order1 piece

brand nameHengli, SUMIKURA

modelHL-1200BS6

payment method

-

update timeFri, 08 Nov 2024 20:50:30 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

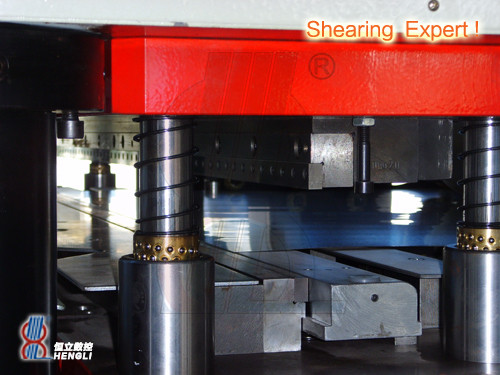

The maximum speed of the model is 150 SPM. The model is composed of uncoiler, flattener, quick change cutter, stackers and etc. The line is using new model uncoiler, the complete line is on the ground without any foundation work. The line also equipped the quick change system. It makes the complicate and difficult change scroll die to be easier. You only need 10 minutes to change a scroll die. It is suitable for the customer who prefer high efficiency.

Name & Model | HL1200BS6 digital-controlled scroll cutting device |

Use | For uncoiling, straightening, high-precise scroll cutting and stacking tinplate or aluminum. It is an important device for can-making or metal-printing companies to reduce tinplate loss and producing cost. |

Electric control | The electric control components use whole set of Mitsubishi control system. |

Material | Tinplate, Blackplate, TFS and Aluminum in tempers normally associated with standard can making material |

Die set | Straight die / Scroll die |

Shear type | Feed-to-stop |

Technical parameters | 1)Sheet width range:500-1200mm |

2)Sheet thickness range:0.125-0.525mm | |

3)Sheet length range:500-1200mm | |

4)Max coil weight:13.5 T | |

5)Nominal coil I.D.:420mm | |

6)Mandrel expansion range:390-440mm | |

7)Coil O.D.:915-1800mm | |

8)Max line speed:120m/min | |

9)Max cutting strokes:150 SPM | |

10) Max bundle weight:2100kg | |

11) Max bundle height:460mm (Including stander) | |

12)Length tolerance range:≤±0.15mm | |

13)Diagonal tolerance range:≤±0.18/1000mm | |

14)Power consumption:about 115kw | |

15)Air consumption:about 1m3/min |

You need a product

You May Like

- Nearest port for product export

- Shanghai

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right