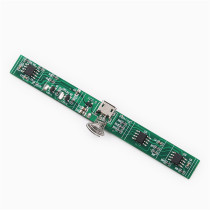

1. Signal flow layout principle: signal flow arrangement -- left input, up input, down output. Avoid interleaving of input, output, high and low levels.

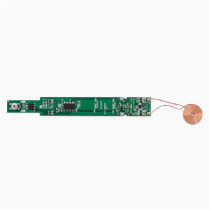

2. Proximity principle: consider the shape of each component. Size. Polarity and number of pins, for the purpose of shortening the alignment, adjust their position and direction.

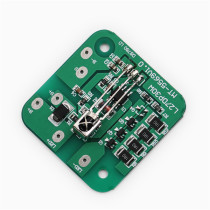

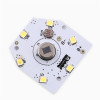

3. Arrangement sequence principle: take each functional circuit as the core component (integrated circuit) as the center, and arrange around it -- the components belonging to the same functional module circuit are arranged together as much as possible. The components which are easy to produce mutual influence or electromagnetic interference should be kept away from or shielded as far as possible. As far as possible, the metal shell components should avoid contact, so as to avoid accidental short circuit caused by discharge, breakdown.

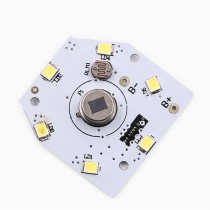

4. Principle of heat dissipation: heating elements should be arranged close to the shell or well-ventilated place with a radiator. For temperature-sensitive components, they should not be placed near the heat source or the upper part of the equipment.

5. Increase the mechanical strength of principle: mainly for large and heavy components, such as power transformer, large electrolytic capacitor, with heat sink of power transistor, etc., of the circuit board layout to pay attention to its center of gravity, gravity and vibration generated under the influence of mechanical stress, electronic print should use mechanical frame or braces, so as to avoid deformation. These components can be transferred to the base if necessary.

6. The principle of easy operation and safety: the arrangement of the whole machine structure should be considered when adjusting the original. In order to ensure the safety of debugging and maintenance, special attention should be paid to the components with high pressure, as far as possible in the operation of human hands can not easily touch.