Fully Automatic Wooden Spoon Fork Hot Pressing Machine

group nameWooden Spoon Making Machine

-

Min Order1 piece

brand nameBesta

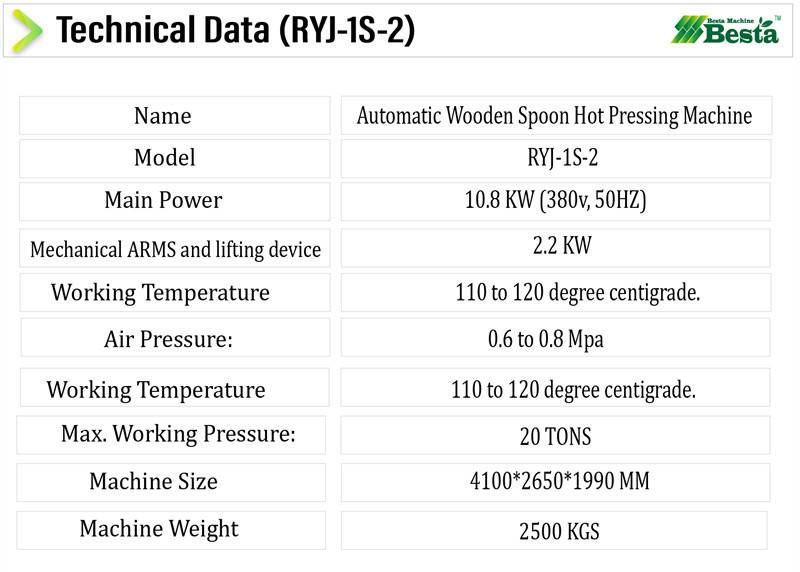

modelRYJ-1S-2

payment methodT/T, L/C

-

update timeTue, 26 Dec 2023 13:45:02 GMT

Packging & Delivery

Weight1500.00kg / piece

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Shanghai, Shenzhen, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents