Automatic Paper Feeder And Cut Roller Laminator FM-390A

group nameLaminator

-

Min Order1 piece

brand nameSUPU

modelFM-390A

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeTue, 05 Nov 2024 13:32:38 GMT

Paramtents

Max laminating width 350mm

Max Laminaitng thickness 350g

Max laminating speed 5 meter /minute

Power 1500W

Motor Power 250W

Max Temperature 160℃

Packging & Delivery

Size122cm x 78cm x 130cm

Weight260.00kg / piece

Min Order1 piece

Briefing

Detailed

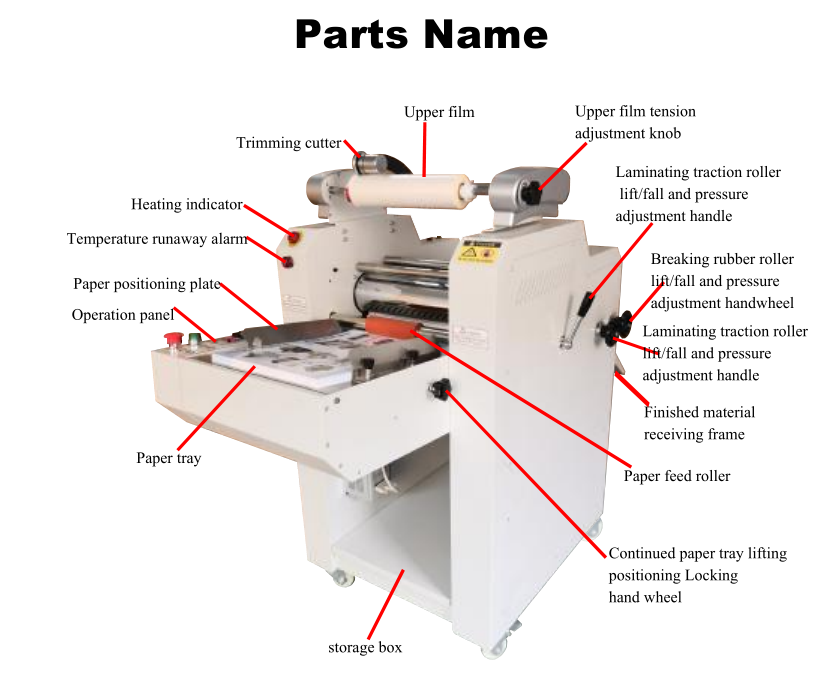

AUTOMATIC PAPER FEEDER AND CUT ROLLER LAMINATOR

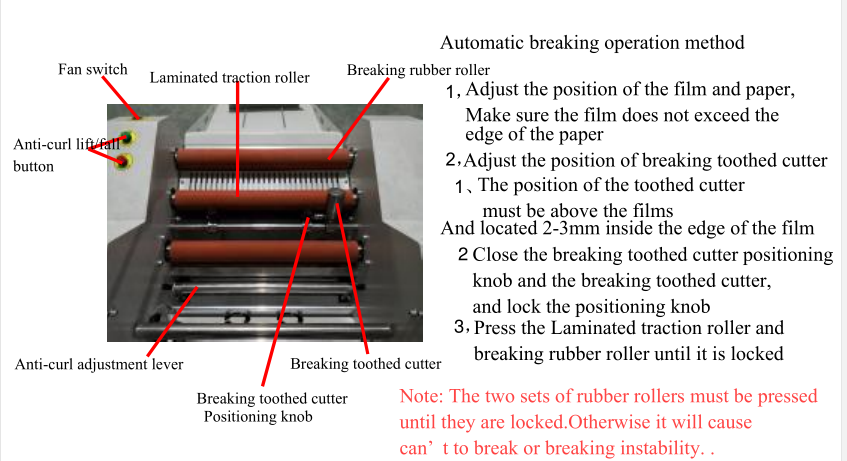

Automatic paper feeder roller laminator for single sided laminating ,with high speed of 5 meter/minute. Electric Adjustment lever can choose different position, solve the problem of different thickness paper anti-curl result. Automatic cutter system and trimmer cutter and dotted line cutter included. Ideal machine for digital printer ,copy center ect ..

Automatic paper feeder make your hands free

Adds new single side Anti-curl functions

Adds Trimming Cutter on left,

Adds the Dotted line cutter on right,

Electric Adjustment lever can choose different position

Maximum:

Max. Width 350mm

Max. thickness up to 350g

Film thickness up to 350g

Single sided laminators are great for laminating shops and small print shops. A single side laminator is the perfect solution for high quality single side lamination of flyers, book covers, posters and more.

You need a product

You May Like

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T