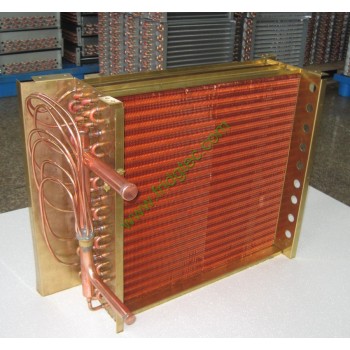

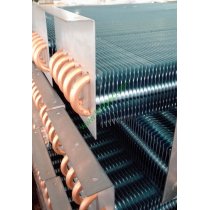

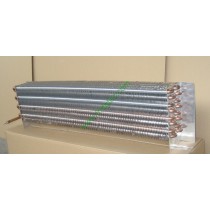

Direct expansion evaporator coils

- US $1.00

100 - 200 piece

group nameCopper tube fin evaporator

-

Min Order100 piece

modelCustomer design

payment methodL/C, D/P, T/T

-

update timeFri, 03 Jan 2020 21:51:08 GMT

Paramtents

Material copper tube, aluminum fin

Corrosion resistant ≥72hrs

Super cleaning compatible to various refrigerant

Packging & Delivery

Min Order100 piece

Briefing

Detailed

Direct Expansion Evaporator coils are engineered and designed to deliver maximum heat transfer efficiency under a wide range of operating conditions. We can offer a wide variety of circuiting coils, including interlaced Row/Face split, to meet the performance requirements of various applications. Evaporator coils are counter flow circuited and have optimized size suction headers and refrigerant distributors. The distributor tubes are of equal lengths to ensure equal distribution of refrigerant into each circuit.

Factory introduction |

Our factory located in Hangzhou, China,10 minutes car distance to our office.

Our factory is ISO 9001 certified, professional in production of copper tubefin evaporator and condenser.

We use high quality material, equipped by high automation machinery like finpunching machine, auto tube flaring machine, automatic welding machine, we haveover 15 years experience in production and with professional technicians tocontrol mold production, IQC, IPQC, FQC and OQC, all products comply with Japan& Italy standard, all these make us achieve good sales increasing year byyear and awarded nice quality reputation among all customers.

Typical benefits and character |

- Well distributed liquid dispensing of windward area ofcondenser coil

- High quality mechanical expanding or super high pressinghydraulic expanding between copper tube and fins, tight contacting andoptimized heat exchanging.

- Free pitch distance selection, reduce the frost affection inlow temperature.

- With single or double reverse-flow system, small waterresistance, good heat exchanging

- With super high temperature vacuum drying, ensure innerwithout impurity or water substance.

Main application & usage |

Productsare suitable for R134A, R22, R404A, R407C, and CO2 refrigerant.

Widely used for commercial refrigerators and freezers, commercial showcase cabinet,air-conditioning systems, dehumidifier, ice maker etc.

Material |

Material: copper tube, aluminum fins, galvanized steel bracket ifneed

- Copper tube: made by Hailiang China,Φ5,Φ7mm,Φ7.94,Φ9.52, Φ12.7, Φ15.88, inner thread groove or smooth tube

- Aluminum foil: blue or other color hydrophilic, or uncoated bare

- Fin type: louver, flat, corrugated or slit fin

- Side plate: galvanized steel plate, stainless steel, aluminum or brass.

Production process |

Tube bending, punching fin, tube expanding, fins installation, drying, welding,leakage test, tube bending, quality inspection, packing

FQC & OQC |

Tightness testing: gas testing under 3.0Mpaair pressure

Leakage testing: water leakagetesting

Pins ready moulds |

No. | Copper tube Diameter | Holes & rows of pitch | Fin | Holes array | Fin surface | Fin edge type |

1 | Φ5/8”(15.88mm) | 50x50mm | 4~10mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

2 | Φ5/8”(15.88mm) | 38x33mm | 2.5~4mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

3 | Φ1/2”(12.7mm) | 31.75x27.5mm | 3~9mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

4 | Φ0.472” (12mm) | 35x35mm | 6~11mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

5 | Φ3/8”(9.52mm) | 25x21.65mm | 1.5~6mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

6 | Φ3/8”(9.52mm) | 31.75x27.5mm | 2.5~7.5mm | Equilateral triangle | Sin-wave & corrugated | Flat + wave |

7 | Φ3/8”(9.52mm) | 25x21.65mm | 1.5~2.5mm | Equilateral triangle | Louver | Flat |

8 | Φ3/8”(9.52mm) | 25.4x19.05mm | 1.8~5mm | Equilateral triangle | Louver | Flat |

9 | Φ5/16”(7.94mm) | 25x21.65mm | 1.5~5mm | Equilateral triangle | Flat | Flat + wave |

10 | Φ0.276” (7mm) | 21x12.7mm | 1.3~1.8mm | Equilateral triangle | Louver | Flat |

We can produce by customer order orsample, also can help customer design and produce different models of condenser& evaporator coil.

Welcome sending your drawing or sample to us.

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A

- Export mode

- Export through agents & Have the independent export and import right