PP245B 3BSC690126R2 Membrane Keyboard Keypad Replacement

group nameAB Other Series

-

Min Order1 piece

brand nameVICPAS

modelPP245B 3BSC690126R2

payment methodWestern Union, MoneyGram, T/T, Paypal, PayPal, Credit Card

-

update timeFri, 08 Nov 2024 11:47:54 GMT

Paramtents

Warranty 365 Days

Product Line Process Panel 245B

Supply Membrane Switch

Shipping 2-3 workdays

Part Number PP245B 3BSC690126R2

Packging & Delivery

Min Order1 piece

Briefing

Detailed

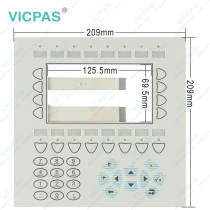

Process Panel 245B PP245B 3BSC690126R2 Membrane Keyboard Keypad Replacement

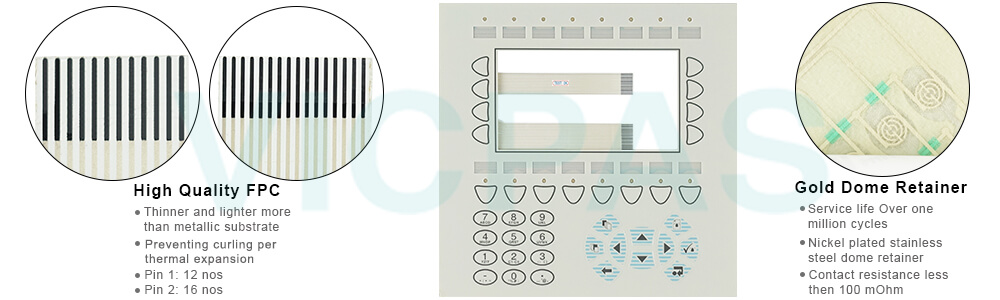

PP245B 3BSC690126R2 Operator Keyboard Process Panel 245B Feature:

Easy to use

A fully deployable PP245B 3BSC690126R2 Operator Panel Keypad HMI with comprehensive and integrated templates and libraries for every conceivable process. The Panel Builder tool, with familiar Microsoft® Windows® environment along with multiple language support results in remarkably quick, easy and efficient engineering.

State-of-the-arts graphics

Vector-based, high-resolution graphics in TFL/LED display, with icon-based interface navigation and control.

Robust and reliable technology

PP245B 3BSC690126R2 Keyboard Membrane Process Panel 245B is constructed in a strong yet lightweight die-cast, powder-coated aluminum housing. IP65/IP66 front casing withstands wet, dusty and demanding environments. Operating temperatures ranging between -30℃ to 70℃ with maximum 95% humidity.

Truly open platform

Built on open architecture and technologies that accompany the .NET framework, these panels are capable of multi-brand controller connectivity. A multitude of connection options are available for local communication, expansion, remote access and more.

Specifications:

The table below describes the parameters of the PP245B 3BSC690126R2 Keyboard Membrane Process Panel 245B.

| Display Type: | TFT LCD |

| Part Number: | PP245B 3BSC690126R2 |

| Product Line: | Process Panel 245B |

| Storage Temperature: | -20 °C to +70 °C |

| Warranty: | 365 Days |

| Backlight Colors: | 64 k colors |

| Backlight Lifetime: | 20,000 hours |

| Brand: | VICPAS |

| Operating Temperature: | -10 °C to +60 °C |

| Screen Brightness: | 450 cd/m2 |

Related Process Panel Terminals Part No. :

| Process Panel | Description | Inventory status |

| PP114 3BSC690097R1 | Process Panel 114 Membrane Keyboard Keypad Repair | In Stock |

| PP114 3BSC690097R2 | Process Panel 114 Operator Keyboard Replacement Repair | In Stock |

| PP210 3BSC690098R2 | Process Panel 210 Series Operator Panel Keypad Repair | Available Now |

| PP220 3BSC690099R1 | Process Panel 220 Membrane Keypad Switch Replacement | Available Now |

| PP220 3BSC690099R2 | Process Panel 220 Series Membrane Keyboard | In Stock |

| PP235 3BSC690102R1 | Process Panel 235 Series Membrane Keypad Replacement | In Stock |

| PP235 3BSC690102R2 | Process Panel 235 Series Terminal Keypad Replacement | Available Now |

| PP245 3BSC690103R1 | Process Panel 245 Series Keyboard Membrane Repair | In Stock |

| PP245 3BSC690103R2 | Process Panel 245 Series Keypad Membrane Replacement | Available Now |

| PP245B 3BSC690126R2 | Process Panel 245B Series Switch Membrane Repair | In Stock |

| PP320 3BSC690100R1 | Process Panel 320 Series Touch Screen Replacement | In Stock |

| PP320 3BSC690100R2 | Process Panel 320 Series Touch Screen Monitor Replacement | In Stock |

| PP325 3BSC690101R2 | Process Panel 325 Series Touch Digitizer Glass Repair | Available Now |

| PP345 3BSC690104R1 | Process Panel 345 HMI Panel Glass Replacement | In Stock |

| PP345 3BSC690104R2 | Process Panel 345 Series HMI Touch Glass Replacement | Available Now |

| PP345B 3BSC690127R2 | Process Panel 345B Series MMI Touch Panel Replacement | In Stock |

| Process Panel Repair | Description | Inventory status |

Process Panel HMI Manuals PDF Download:

FAQ:

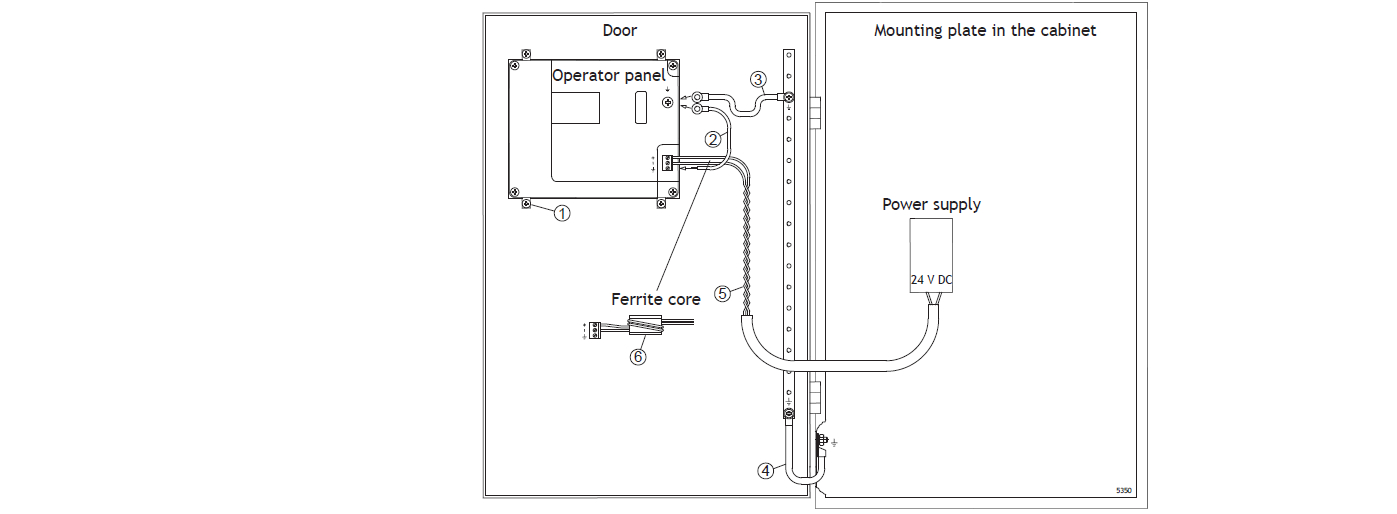

Question: Grounding the PP245B 3BSC690126R2 Terminal Keypad operator panel

Solution:

The mounting clamps of the operator panel do not provide a secure grounding connection between the panel and the device cabinet, see 1 in drawing above.

1. Connect a wire, that is sized correctly according to local electrical codes, between the quick-connect terminal connector on the operator panel and the chassis of the panel, see 2 in drawing above.

2. Connect a wire or grounding braid, that is sized correctly according to local electrical codes, between the chassis of the operator panel and the closest grounding point on the door, see 3 in drawing above.

3. Connect a strong but short grounding braid between the door and the device cabinet, see 4 in drawing above.

4. Twist the cables onto the 24 V DC feed, see 5 in drawing above.

2 turns around the ferrite core provide 4 times the suppression of 1 turn.

3 turns around the ferrite core provide 9 times the suppression of 1 turn.

A ferrite core suppresses disturbances to the 24 V feed, see 6 in drawing above.

The grounding wires should be short and the conductor should have a large area.

A long, thin grounding wire has a very high impedance (resistance) at high frequencies and does not guide disturbances to the ground.

Multi-wire conductors are better than single wire conductors with the same area.

A braided conductor wire with the same area is even better. The best is a short, thick grounding braid.

Common misspellings:

PP245B 3BSC69026R2P245B 3BSC690126R2

PP245B 3BSC6901262R

PP2458 3BSC690126R2

PP245B 3BSCC690126R2

You need a product

You May Like

- Nearest port for product export

- Guangzhou, Hongknog, Shenzhen, Taiwan

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow