PP345 3BSC690104R1 Touch Screen Glass Replacement

group nameAB Other Series

-

Min Order1 piece

brand nameVICPAS

modelPP345 3BSC690104R1

payment methodWestern Union, MoneyGram, T/T, Paypal, PayPal, Credit Card

-

update timeFri, 08 Nov 2024 15:09:22 GMT

Paramtents

Warranty 365 Days

Product Line Process Panel 345

Supply Touch Screen Panel

Shipping 2-3 workdays

Part Number PP345 3BSC690104R1

Touch Size 10.4 inches

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Process Panel 345 PP345 3BSC690104R1 HMI Touch Screen Repair Replacement

VICPAS supply Process Panel 345 PP345 3BSC690104R1 Touch Screen with 365 Days warranty and support Urgent Worldwide Shipping.

Process Panel 345 is a user-friendly, intuitive and ergonomic operator panel that combines slim, space-saving dimensions with a comprehensive range of advanced functions. PP345 3BSC690104R1 Touch Screen Tablet Process Panel 345 family comprises user-friendly, intuitive and ergonomic operator panels that combine slim, space-saving dimensions with a comprehensive range of advanced functions. Adding to the already well-established feature-rich Process Panel 345 our new Rugged and Black panels are designed to perform in challenging harsh environments. Whether it is heavy outdoor use, usage in areas with explosion risk, or ship bridge use in marine applications, they are ready to provide you with the information needed.

Designed to make process automation easy, PP345 3BSC690104R1 Touchscreen HMI panels are equipped with advanced process and equipment control functionality, maneuvered by touching the LCD display. With market-leading performance and stunning graphical ability, Process Panel 345 erodes the line between ordinary Operator Panels and PC- based HMIs. Panels are configured using Panel Builder tool which contains a wide range of advanced functions. The functions are tested and developed with customer needs and preferences in focus.

Specifications:

The table below describes the parameters of the PP345 3BSC690104R1 Touch Panel Process Panel 345.

| Brand: | VICPAS |

| Part Number: | PP345 3BSC690104R1 |

| Product Line: | Process Panel 345 |

| Backlight: | LED/CFL |

| Display Type: | TFT Color LCD |

| Backlight Lifetime: | 50,000 hours |

| Display Resolution: | 1024 × 768 pixels |

| Operating Temperature: | -10 °C to +60 °C |

| Storage Temperature: | -20 °C to +70 °C |

| Warranty: | 365 Days |

Related Process Panel Terminals Part No. :

| Process Panel | Description | Inventory status |

| PP114 3BSC690097R1 | Process Panel 114 Membrane Keyboard Keypad Repair | In Stock |

| PP114 3BSC690097R2 | Process Panel 114 Operator Keyboard Replacement Repair | In Stock |

| PP210 3BSC690098R2 | Process Panel 210 Series Operator Panel Keypad Repair | Available Now |

| PP220 3BSC690099R1 | Process Panel 220 Membrane Keypad Switch Replacement | Available Now |

| PP220 3BSC690099R2 | Process Panel 220 Series Membrane Keyboard | In Stock |

| PP235 3BSC690102R1 | Process Panel 235 Series Membrane Keypad Replacement | In Stock |

| PP235 3BSC690102R2 | Process Panel 235 Series Terminal Keypad Replacement | Available Now |

| PP245 3BSC690103R1 | Process Panel 245 Series Keyboard Membrane Repair | In Stock |

| PP245 3BSC690103R2 | Process Panel 245 Series Keypad Membrane Replacement | Available Now |

| PP245B 3BSC690126R2 | Process Panel 245B Series Switch Membrane Repair | In Stock |

| PP320 3BSC690100R1 | Process Panel 320 Series Touch Screen Replacement | In Stock |

| PP320 3BSC690100R2 | Process Panel 320 Series Touch Screen Monitor Replacement | In Stock |

| PP325 3BSC690101R2 | Process Panel 325 Series Touch Digitizer Glass Repair | Available Now |

| PP345 3BSC690104R1 | Process Panel 345 HMI Panel Glass Replacement | In Stock |

| PP345 3BSC690104R2 | Process Panel 345 Series HMI Touch Glass Replacement | Available Now |

| PP345B 3BSC690127R2 | Process Panel 345B Series MMI Touch Panel Replacement | In Stock |

| Process Panel Repair | Description | Inventory status |

Process Panel HMI Manuals PDF Download:

FAQ:

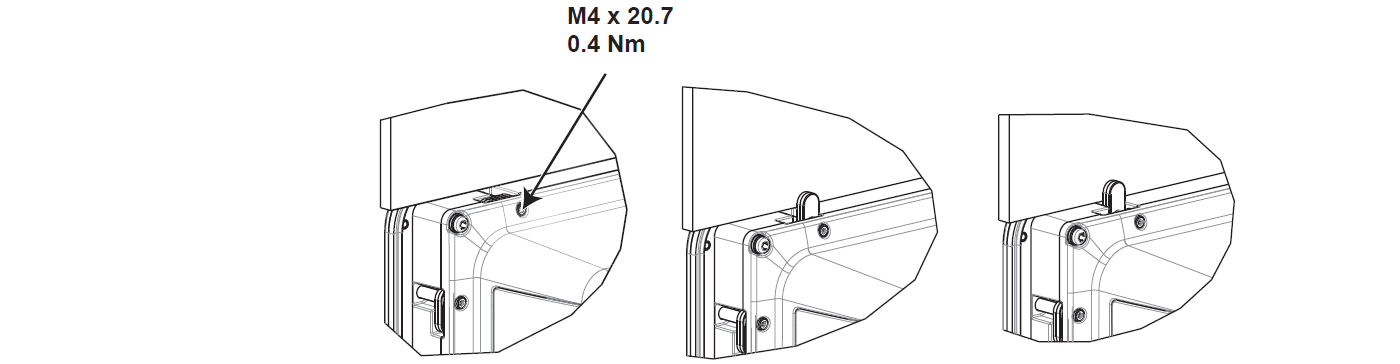

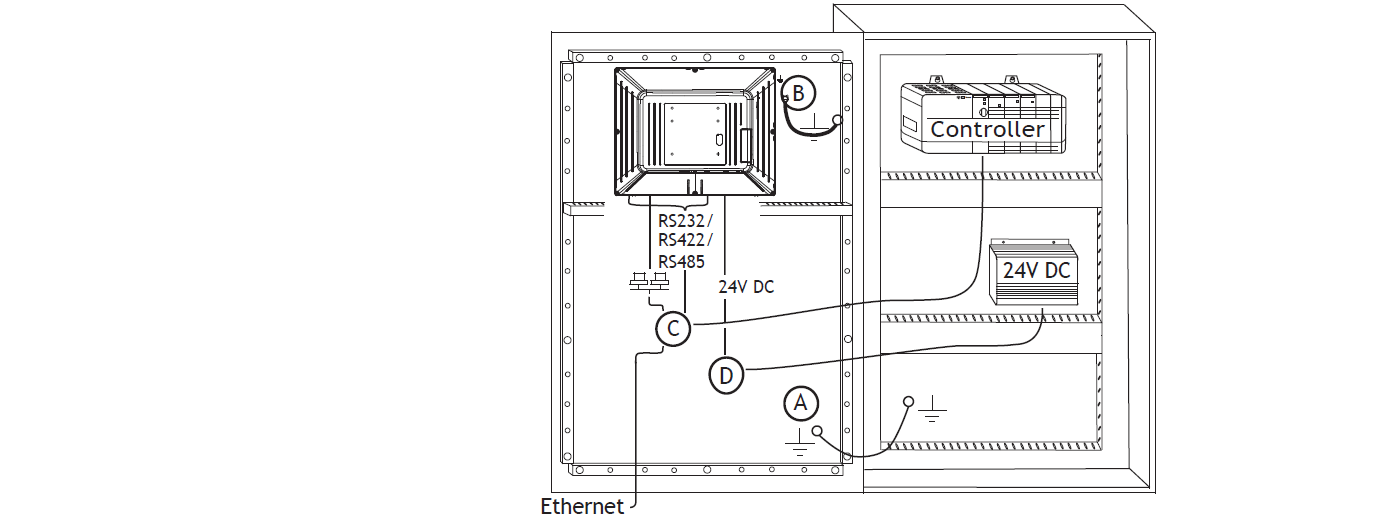

Question: Installation Process

Solution: The following is needed:

• ATorxTX7screwdriver

1. Unpack and check the delivery. If damage is found, notify the supplier.

2. Place the operator panel on a stable surface during installation. Dropping the operator panel or letting it fall may cause damage.

3. To cut a correct opening for the operator panel, use the cut out dimensions in the outline drawing.

4. Secure the operator panel in position by screwing the M4 Torx screw, allowing the built-in bracket to tighten against the panel:

5. Connect the cables in the specified order, according to the drawing and steps below.

• The operator panel must be brought to ambient temperature before it is started up. If condensation forms, ensure that the operator panel is dry before connecting it to the power outlet.

• Ensure that the operator panel and the controller system have the same electrical grounding (reference voltage level), otherwise errors in communication may occur.

• Ensure that the voltage and polarity of the power source is correct.

• Separate high voltage cables from signal and supply cables.

• Shielded communication cables are recommended.

– Connect cable A.

– Connect cable B, using an M5 screw and a grounding conductor (as short as possible), that is sized correctly according to local electrical codes.

– Connect cable C.

– Connect cable D. The recommended cross-section of the cable is 1.5 mm2..

6. Carefully remove the protective film over the operator panel display, take care to avoid static electricity that could damage the panel.

Common misspellings:

PP345 3BSC60104R1P345 3BSC690104R1

PP345 3BSC6901041R

PP345 38SC690104R1

PP3455 3BSC690104R1

You need a product

You May Like

- Nearest port for product export

- Guangzhou, Hongknog, Shenzhen, Taiwan

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow