AlNico Magnet

group nameAlNiCo Magnet

-

Min Order1 piece

brand nameVector Magnets

payment method

-

update timeTue, 26 May 2020 16:16:16 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

- <p> Alnico is an acronym referring to a family of iron alloys which in addition to iron are composed primarily of aluminium (Al), nickel (Ni) and cobalt (Co), hence al-ni-co. They also include copper, and sometimes titanium. Alnico alloys are ferromagnetic, with a high coercivity (resistance to loss of magnetism) and are used to make permanent magnets. Before the development of rare earth magnets in the 1970s, they were the strongest type of permanent magnet. Other trade names for alloys in this family are: Alni, Alcomax, Hycomax, Columax, and Ticonal.<p><p> The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe. The development of alnico began in 1931, when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminum had a coercivity of 400 oersted (Oe; 32 kA/m), double that of the best magnet steels of the time.

- <p> Alnico alloys make strong permanent magnets, and can be magnetised to produce strong magnetic fields. Of the more commonly available magnets, only rare-earth magnets such as neodymium and samarium-cobalt are stronger. Alnico magnets produce magnetic field strength at their poles as high as 1500 gauss (0.15 tesla), or about 3000 times the strength of Earth's magnetic field. Some brands of alnico are isotropic and can be efficiently magnetized in any direction. Other types, such as alnico 5 and alnico 8, are anisotropic, with each having a preferred direction of magnetization, or orientation. Anisotropic alloys generally have greater magnetic capacity in a preferred orientation than isotropic types.

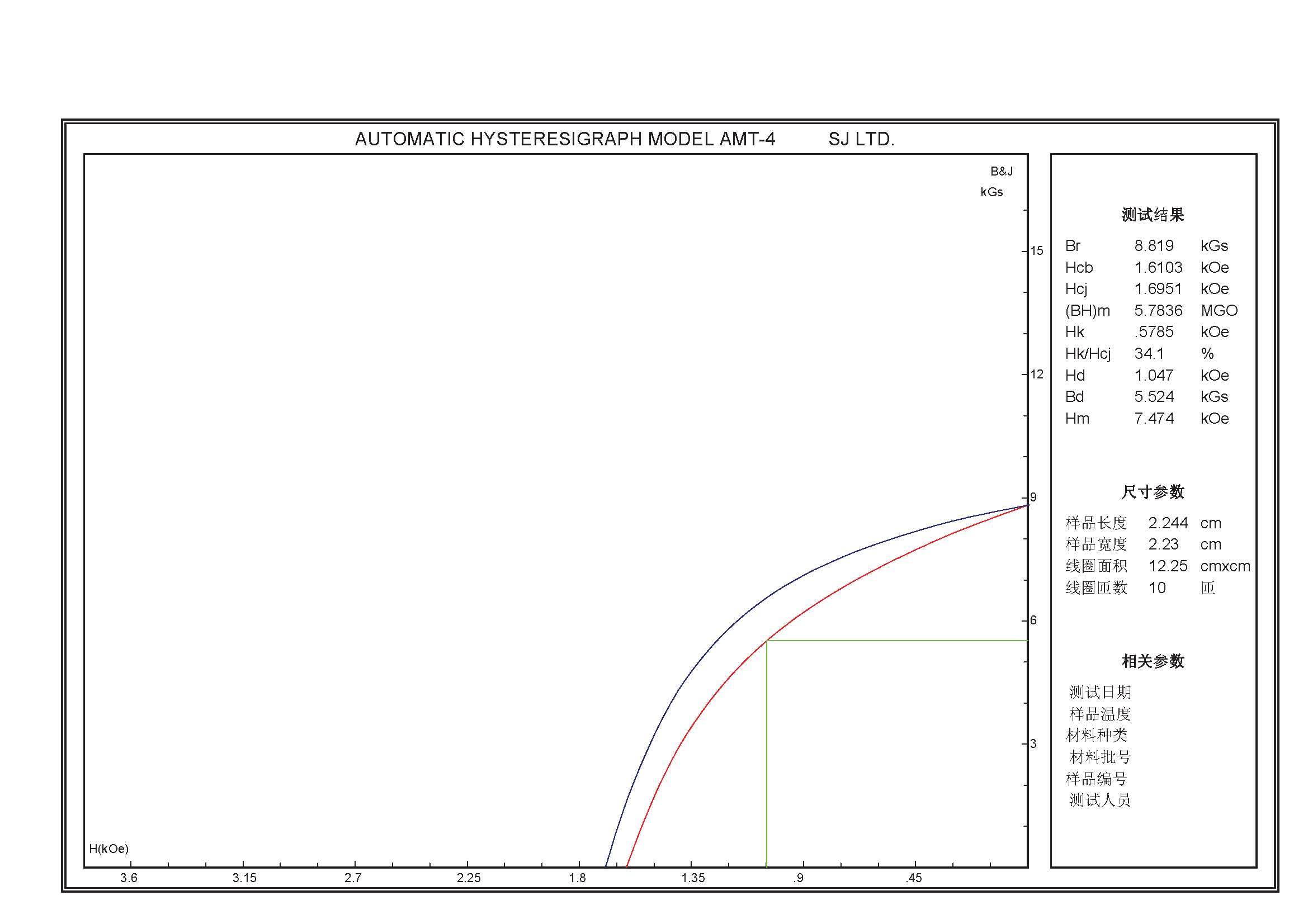

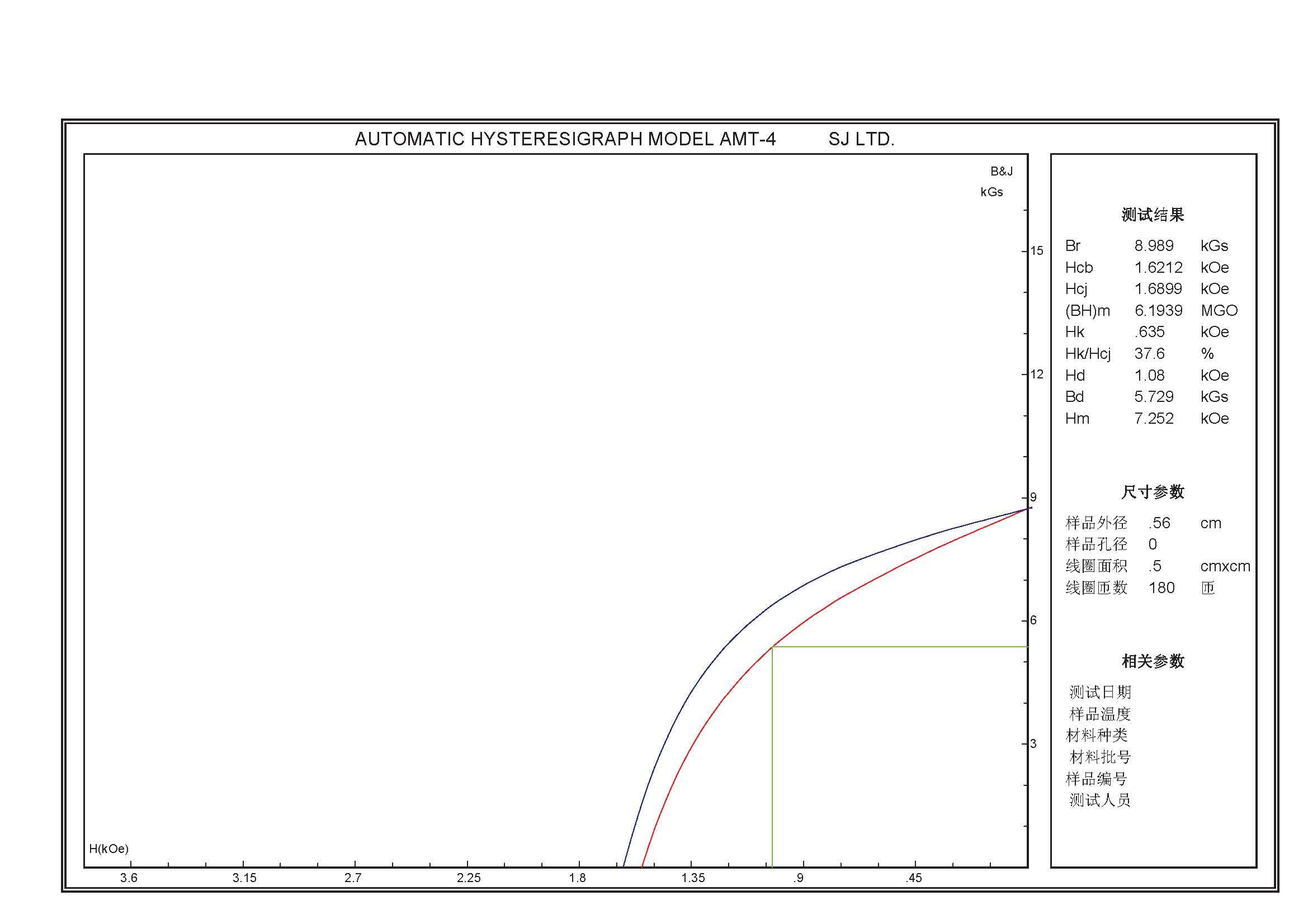

<p> Alnico's remanence (Br) may exceed 12,000 G (1.2 T), its coercivity (Hc) can be up to 1000 oersted (80 kA/m), its energy product ((BH)max) can be up to 5.5 MG·Oe (44 T·A/m). This means alnico can produce a strong magnetic flux in closed magnetic circuit, but has relatively small resistance against demagnetization. The field strength at the poles of any permanent magnet depends very much on the shape and is usually well below the remanence strength of the material.

<p> Alnico alloys have some of the highest Curie temperatures of any magnetic material, around 800 °C (1,470 °F), although the maximum working temperature is normally limited to around 538 °C (1,000 °F). They are the only magnets that have useful magnetism even when heated red-hot. This property, as well as its brittleness and high melting point, is the result of the strong tendency toward order due to intermetallic bonding between aluminium and its other constituents. They are also one of the most stable magnets if they are handled properly. Alnico magnets are electrically conductive, unlike ceramic magnets.<p>1、High Magnetic Property: the magnet property of bonded NdFeB magnet is between that of sintered NdFeB and ferrite, and with good consistency and stability.<p>

<p>2、Large Freeness of Product Shapes and High Precision of Dimension: the magnet shape and dimension are decided by the tooling, like ring, segment, block, etc., without further sintering and mechanical machining processes.<p>

<p>3、Good Corrosion Resistance: after electrodeposited or through other special treatments, it can be used under normal or unfavorable environment conditions for a long time.<p>

<p>4、Diverse magnetization: Multi-pole magnetization and screw angle magnetization are available, and the field distribution could be square, sinusoid and so on. - <p>1. Inner magnetic voltmeter/ammeter, electronic type power energy measuring instrument, avometer, flowmeter<p>2. A wide range of magnetic sensor, polarized relay, temperature and pressure controller<p>3. Buzzer of Mobile phone, hearing aids, mini speaker<p>4. lighter of automobile, odometer of automobile and motorcycle, permanent motor, absorptive appliance. <p>5. Widely applied in high stability fields like aviation, spaceflight and military technology<p>6. Motorcycle, permanent motor, absorptive appliance

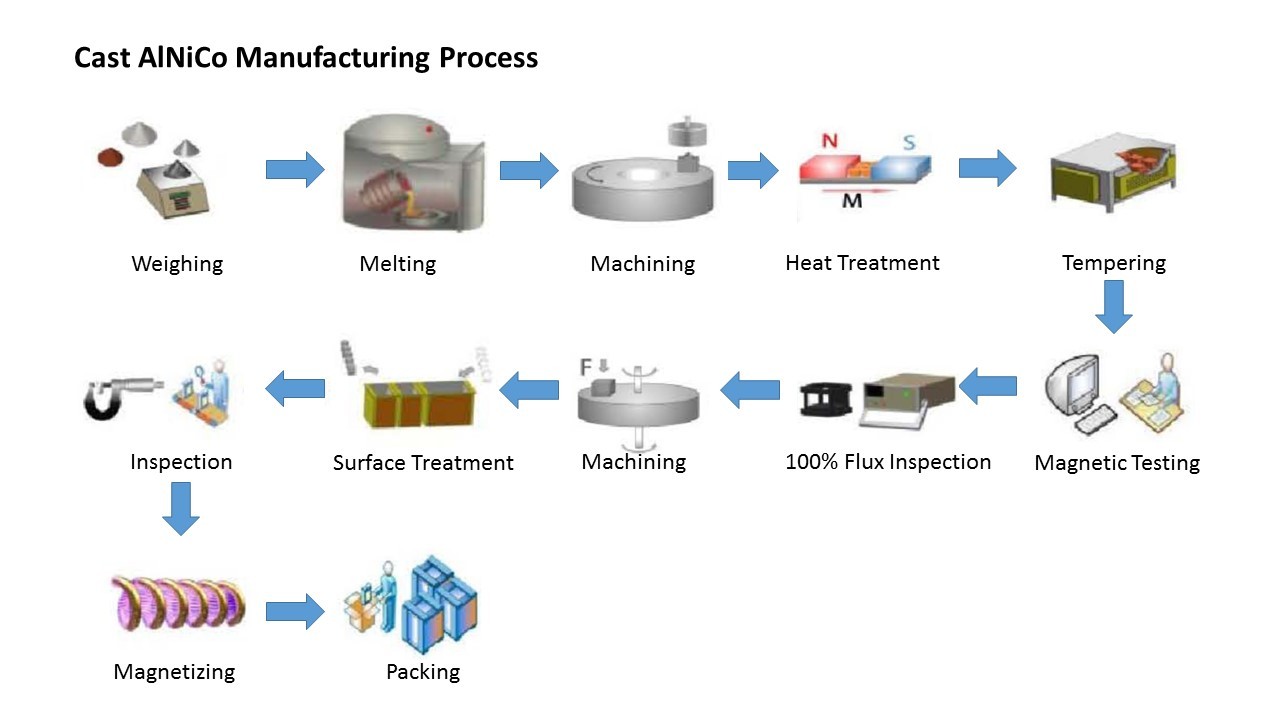

Cast AlNiCo Demagnetisation Curve

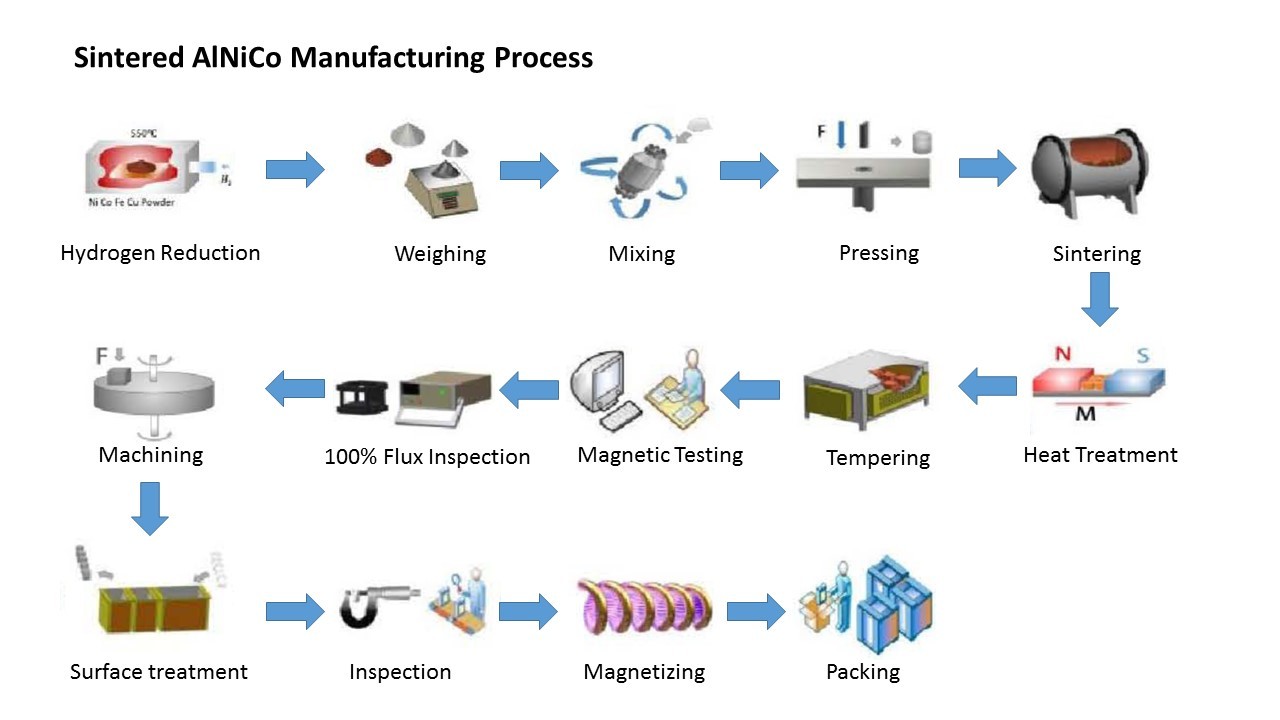

Sintered AlNiCo Demagnetisation Curve

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shanghai, Ningbo, Tianjin, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow