Sintered Smco Magnets

group nameSmCo Magnet

-

Min Order1 piece

brand nameVector Magnets

payment method

-

update timeTue, 26 May 2020 16:15:21 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

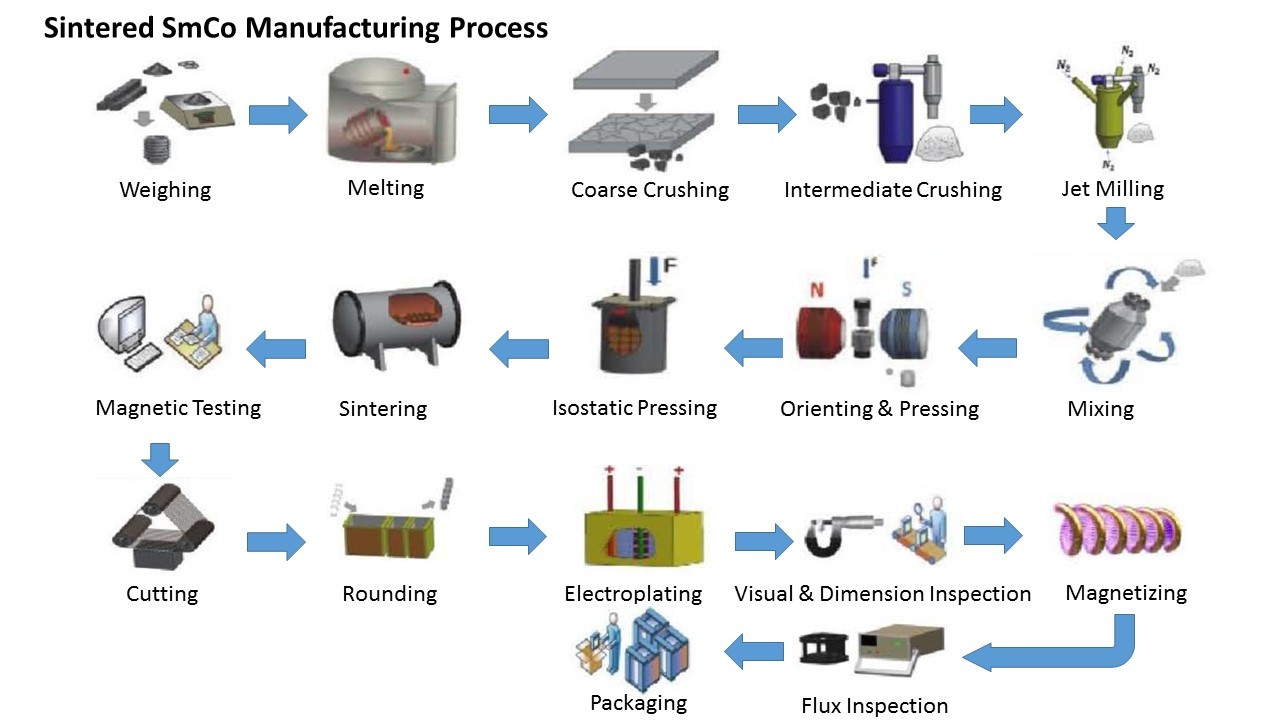

- <p> A samarium–cobalt (SmCo) magnet, a type of rare earth magnet, is a strong permanent magnet made of an alloy of samarium and cobalt. They were developed in the early 1970s by Albert Gale and Dilip K. Das of Raytheon Corporation. They are generally ranked similarly in strength to neodymium magnets, but have higher temperature ratings and higher coercivity. They are brittle, and prone to cracking and chipping. Samarium–cobalt magnets have maximum energy products (BHmax) that range from 16 megagauss-oersteds (MGOe) to 33 MGOe, that is approx. 128 kJ/m3 to 264 kJ/m3; their theoretical limit is 34 MGOe, about 272 kJ/m3. They are available in two "series", namely Series 1:5 and Series 2:17.<p><p> Sintered Samarium Cobalt magnets exhibit magnetic anisotropy, meaning they can only be magnetized in the axis of their magnetic orientation. This is done by aligning the crystal structure of the material during the manufacturing process.<p> SmCo assemblies can be fabricated by adhering magnets with adhesives to suit a range of environments, by mechanically fastening magnets, or by a combination of these methods. Due to the relatively brittle nature of these magnet materials, press fits are not recommended.<p> When multiple magnets are assembled in repelling positions, it is advisable to use mechanical fastening in addition to adhesives, since if adhesives were to give way, repelling magnets may dislodge and endanger personnel using them. Our design engineering team will be happy to assist you in designing housings for your magnet assemblies.

- <p>Series 1:5

<p> These samarium–cobalt magnet alloys (generally written as SmCo5, or SmCo Series 1:5) have one atom of rare earth samarium per five atoms of cobalt. By weight this magnet alloy will typically contain 36% samarium with the balance cobalt. The energy products of these samarium–cobalt alloys range from 16 MGOe to 25 MGOe, that is, approx. 128 - 200 kJ/m3. These samarium–cobalt magnets generally have a reversible temperature coefficient of -0.05%/°C. Saturation magnetization can be achieved with a moderate magnetizing field. This series of magnet is easier to calibrate to a specific magnetic field than the SmCo 2:17 series magnets.<p> In the presence of a moderately strong magnetic field, unmagnetized magnets of this series will try to align their orientation axis to the magnetic field, thus becoming slightly magnetized. This can be an issue if post-processing requires that the magnet be plated or coated. The slight field that the magnet picks up can attract debris during the plating or coating process, causing coating failure or a mechanically out-of-tolerance condition.

<p>Series 2:17

<p> These alloys (written as Sm2Co17, or SmCo Series 2:17) are age-hardened with a composition of two atoms of rare-earth samarium per 13–17 atoms of transition metals (TM). The TM content is rich in cobalt, but contains other elements such as iron and copper. Other elements like zirconium, hafnium, and such may be added in small quantities to achieve better heat treatment response. By weight, the alloy will generally contain 25% of samarium. The maximum energy products of these alloys range from 20 to 32 MGOe, what is about 160-260 kJ/m3. These alloys have the best reversible temperature coefficient of all rare-earth alloys, typically being -0.03%/°C. The "second generation" materials can also be used at higher temperatures. <p>Pros:

<p> 1. High (BH)max (energy product)<p> 2. With low temperature coefficient and excellent stability, SmCo magnets can operate at temperatures up to 350℃, depending upon the grade and permeance coefficient. Sm2Co17 materials exhibit superior temperature characteristics as compared to the Sm1Co5 types. In 180℃+ environment, SmCo magnets outclass NdFeB magnets in magnetic performance and stability.<p> 3. The corrosion resistance of SmCo is considered good while that of NdFeB is considered poor. Coatings for corrosion resistance are therefore not generally required for SmCo magnets.

<p>Cons:

<p> 1. SmCo is extremely brittle, and highly prone to chipping and cracking. They must therefore be handled very carefully to avoid damage and injury to personnel handling the magnets. Receiving and assembly personnel should be warned about the dangers of handling magnetized Rare Earth magnets. Special machining techniques, involving diamond-grinding techniques, must be used to machine this material.<p> 2. relatively higher cost - <p> SmCo magnets are liked by material engineers in high temperature applications, say magnetic bearing, magnetic couplings, sensors, high performance stepper, DC, servo, linear and voice coil motors, high-end loudspeakers, headphones, microphones, magnetic separation, instrumentation, switches, relays, magnetic resonance, sputtering vacuum deposition, charged particle beam guidance, particle accelerators, Halbach arrays, microwave components, etc in automobiles, airplanes, military defense, etc.<p>Other uses include:<p> 1. High-end electric motors used in the more competitive classes in slot car racing<p> 2. Turbo machinery<p> 3. Traveling-wave tube field magnets<p> 4. Applications that will require the system to function at cryogenic temperatures or very hot temperatures (over 180 °C)<p> 5. Applications in which performance is required to be consistent with temperature change<p> 6. Bench top NMR spectrometers

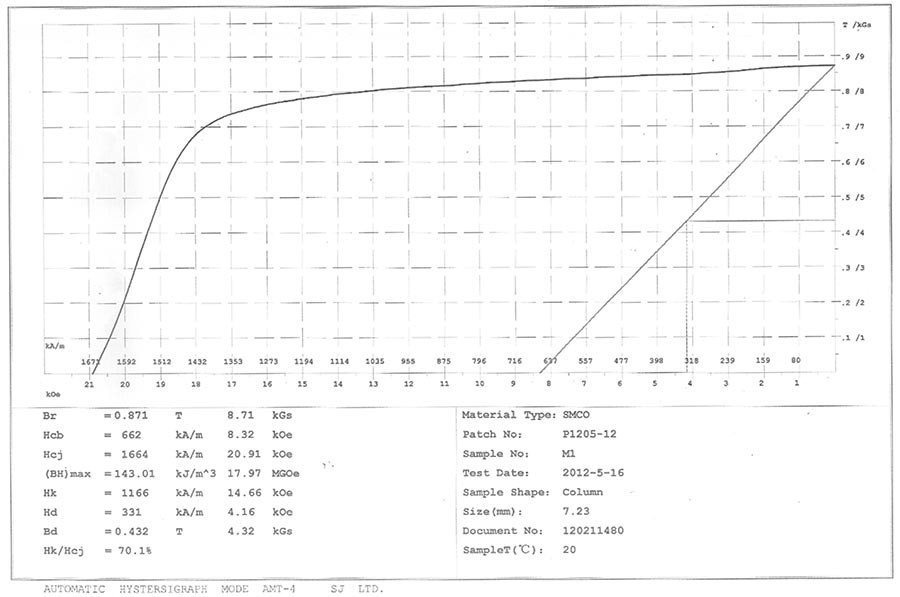

Sintered 1:5 Demagnetisation Curve (SmCo18)

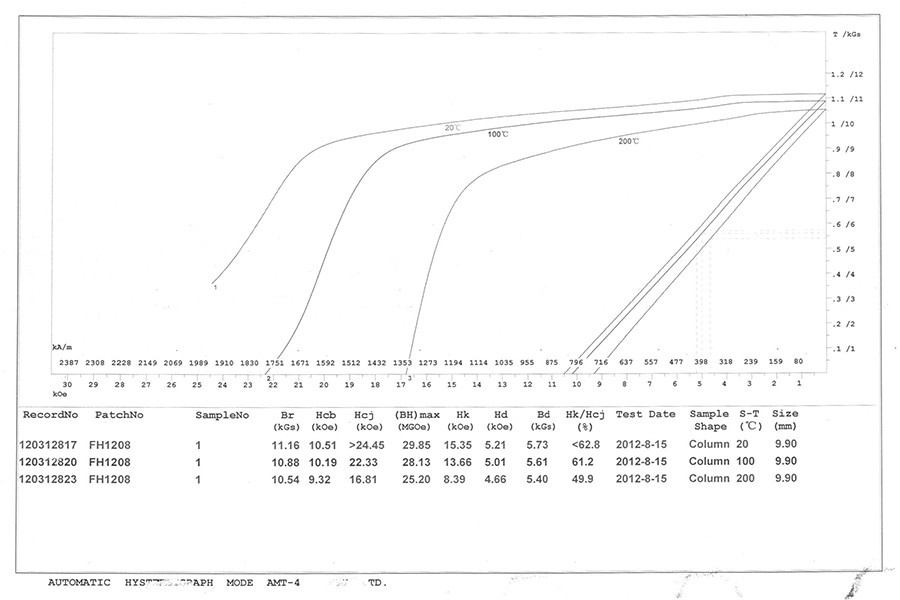

Sintered SmCo 2:17 Demagnetisation Curve (SmCo32H)

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo, Tianjin, Shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow