refrigerated air dryer specification

- US $600.00

1 - 1 unit

group nameRefrigerated air dryer

-

Min Order1 unit

brand nameSHANLI

modelSLAD-6NF

payment methodL/C, D/A, D/P, Western Union, T/T

-

update timeTue, 05 Nov 2024 11:52:19 GMT

Paramtents

Air inlet temp ≤60°C

Cooling way Air-cooled

Ambient temp ≤50°C

Pressure dew point 2~10°C

Air inlet pressure 0.6~1.6MPa

Heat exchanger plate-fin heat exchanger

Place of origin Hangzhou, China

Capacity 6.5m3/min

Warranty 18 months

Color depend on requirement

Packging & Delivery

Size105cm x 64cm x 76cm

Weight160.00kg / unit

Min Order1 unit

Briefing

Detailed

Product name: Air-cooled refrigerated air dryer

Product model: SLAD-6NF

Product Function

● Dry, quality air is vital for long-term, trouble-free operation of your processes. SHANLI SLAD series dryers protect your products and systems against damage or corrosion.

● They remove moisture from compressed air with a dew point as low as 2-10 °C/35.6-50 °F. Easy to install, simple to operate and reliable, they provide the dry air you need, allowing you to concentrate on your core business.

Technical Specifications

● Pressure range: 0.6-1.6 Mpa

● Max air inlet temp.: 60 Deg C

● Max ambient temp.: 50 Deg C

● Cooling method: air cooled type / water-cooled type

● Pressure dew point: 5 Deg C

● Power: 220/380V-1PH-50HZ

● Refrigerant: R-22 (R-407C, R-134A as optional)

Note: Refrigerated air dryer without metal box board for over 80 m3/ min. Other special standards can be customized.

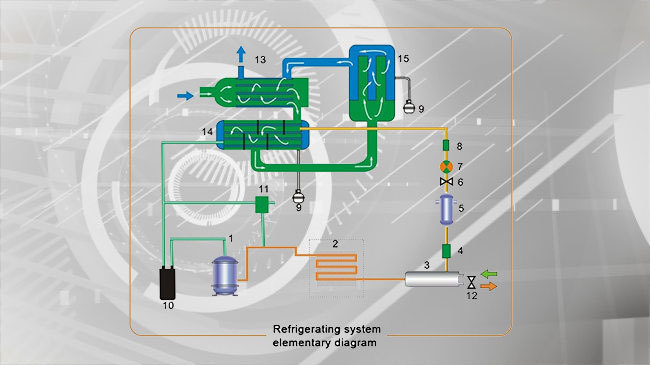

Working Principle

Refrigeration compressed air dryer makes the water vapor in the compressed air condenses into droplets through cooling so as to achieve the purpose of reducing moisture content. Condensed droplets are discharged by the automatic drainage system.

Annotation:

| 1. Cooling medium compressor | 6. Manual valve | 11. Hot gas by-pass valve |

|---|---|---|

| 2. Air condenser | 7. Cooling medium sight glass | 12. Water volume adjustable valve |

| 3. Water condenser | 8. Expansion valve | 13. Pre-cooling gas |

| 4. Magnetic valve | 9. Automatic drainer | 14. Evaporator |

| 5. Drying filter | 10. Gas water separator | 15. Effective separator |

Performance Parameters

| Refrigerated Compressed Air Dryer | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Flow Capacity (Nm3/min) | Voltage (V) | Fan Power (W) | Pipe Diameter | Air Inlet Pressure (Mpa) | Net Weight (Kg) | Length (mm) | Width (mm) | Height (mm) | Air Flow (N3/h) |

| SLAD-0.5NF | 0.65 | 220 | 1x67 | G1/2" | 0.6-1.0 MPa | 45 | 750 | 430 | 610 | 760 |

| SLAD-1NF | 1.2 | 220 | 1x67 | G1" | 70 | 780 | 450 | 610 | 760 | |

| SLAD-2NF | 2.5 | 220 | 1x95 | G1" | 110 | 800 | 460 | 720 | 1580 | |

| SLAD-3NF | 3.6 | 220 | 1x150 | G1" | 130 | 950 | 480 | 720 | 3150 | |

| SLAD-4.5NF | 5 | 220 | 1x240 | G1 1/2" | 150 | 1170 | 540 | 750 | 5580 | |

| SLAD-6NF | 6.8 | 220 | 2x150 | G1 1/2" | 160 | 1350 | 520 | 753 | 6300 | |

| SLAD-8NF | 8.5 | 220 | 2x195 | G2" | 200 | 1100 | 670 | 1098 | 8470 | |

| SLAD-10NF | 10.9 | 380 | 2x195 | G2" | 250 | 1200 | 670 | 1098 | 8470 | |

| SLAD-12NF | 12.8 | 380 | 2x195 | G2" | 300 | 1200 | 670 | 1048 | 8470 | |

| SLAD-15NF | 16 | 380 | 2x190 | DN65 | 320 | 1460 | 750 | 1630 | 8470 | |

| SLAD-20NF | 22 | 380 | 2x240 | DN65 | 420 | 1670 | 800 | 1663 | 11160 | |

| SLAD-25NF | 26.8 | 380 | 2x240 | DN80 | 550 | 1820 | 800 | 1713 | 11160 | |

| SLAD-30NF | 32 | 380 | 2x380 | DN80 | 650 | 1900 | 860 | 1875 | 15240 | |

| SLAD-40NF | 43.5 | 380 | 3x240 | DN100 | 2200 | 2200 | 930 | 1941 | 16740 | |

| SLAD-50NF | 53 | 380 | 3x380 | DN100 | 2450 | 2450 | 900 | 2110 | 22860 | |

| SLAD-60NF | 67 | 380 | 4x380 | DN125 | 2140 | 2140 | 1450 | 1787 | 30480 | |

| SLAD-80NF | 90 | 380 | 4x550 | DN125 | 2070 | 2070 | 1600 | 2029 | 42400 |

Contamination Reduces

Efficiency

The air we breathe contains contamination

in the form of water vapour and airborne

particles.

During the compression process an air

compressor concentrates these contaminants

and depending on the design and age will

even add to the contamination in the form

of oil carry over.

Modern air compressors generally have built

in aftercoolers that reduce the discharge

temperature of the compressed air and with

the help of water separators, remove the bulk

of liquid water.

In some applications this may be sufficient,

but the remaining dirt and moisture content

suspended in aerosol form, can, if not

removed, damage the compressed air system

and cause product spoilage.

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai, Guangzhou, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Cash