Widely used in petrochemical, thermal power plants and other oil, water pipe as a connect or cut off device

Brief Introduction

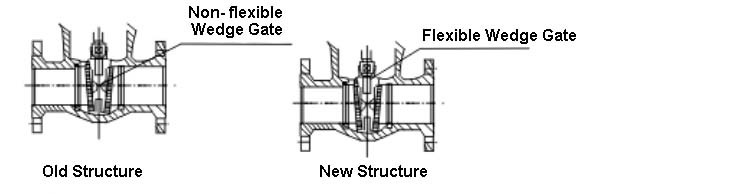

Traditional gate valve sealing structure has a big problem, the structure is inelastic, single gate seal, sealing surface is easy to scratch and leak, and also because of the casting steel valve body and gate internal stress is not completely eliminated, in the course of use, due to the impact of time and temperature, the valve body and the gate seal surface will deform under the action of its own internal stress, once the deformation happened, wedge gate sealing surface and the valve seat sealing surface can not fully contact each other, the sealing does not meet the requirements.

Our company introduced the United States advanced technology, the gate we use is a flexible structure, both sides the central around of the gate is made with specified elastic groove, so that the gate has a certain flexibility. When valve seat two side sealing surface and wedge gate sealing surface slightly deformed and can not be completely meet each other, elastic groove can be used to adjust sealing, completely solve the traditional structural defects. (See Figure Below)

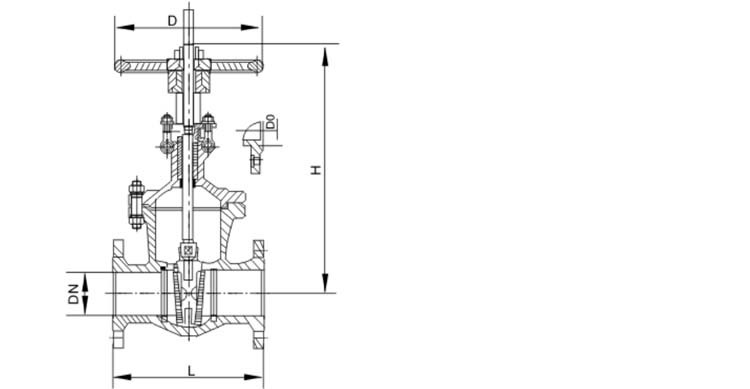

Compact structure, reasonable design, good valve rigidity, smooth flow path, flow resistance coefficient is small. Sealing surface uses stainless steel and hard alloy, long service life. With flexible graphite packing, sealing is reliable, and easy to operate. Actuator could be manual, electric, pneumatic, gear box. Structural type: Elastic wedge single gate, rigid wedge single gate and double gate model. Widely used in petrochemical, thermal power plants and other oil, water pipe as a connect or cut off device.

Main Material

Body, Bonnet | Gate | Seat | Stem | Packing | Medium | Temperature |

WCB | WCB+D507Mo | D577 | 2Cr13 | Flexible graphite | Water, oil, steam | ≤425℃ |

ZG1Cr5Mo | ZG1Cr5Mo+Stellite12 | 1Cr18Ni9+Stellite6 | 25Cr2Mo1VA | Flexible graphite | Water, oil, steam | ≤550℃ |

ZG1Cr18Ni9Ti | Cr1Ni2 | 1Cr18Ni9+Stellite6 | 1Cr18Ni9Ti | PTFE | Nitric acid, alkali | ≤200℃ |

ZG00Cr17Ni14Mo2 | 316L+ Stellite12 | 316L+ Stellite6 | 316L | PTFE | Urea, methylamine, phosphoric acid | ≤200℃ |

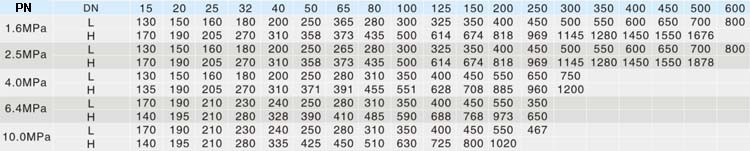

Dimension