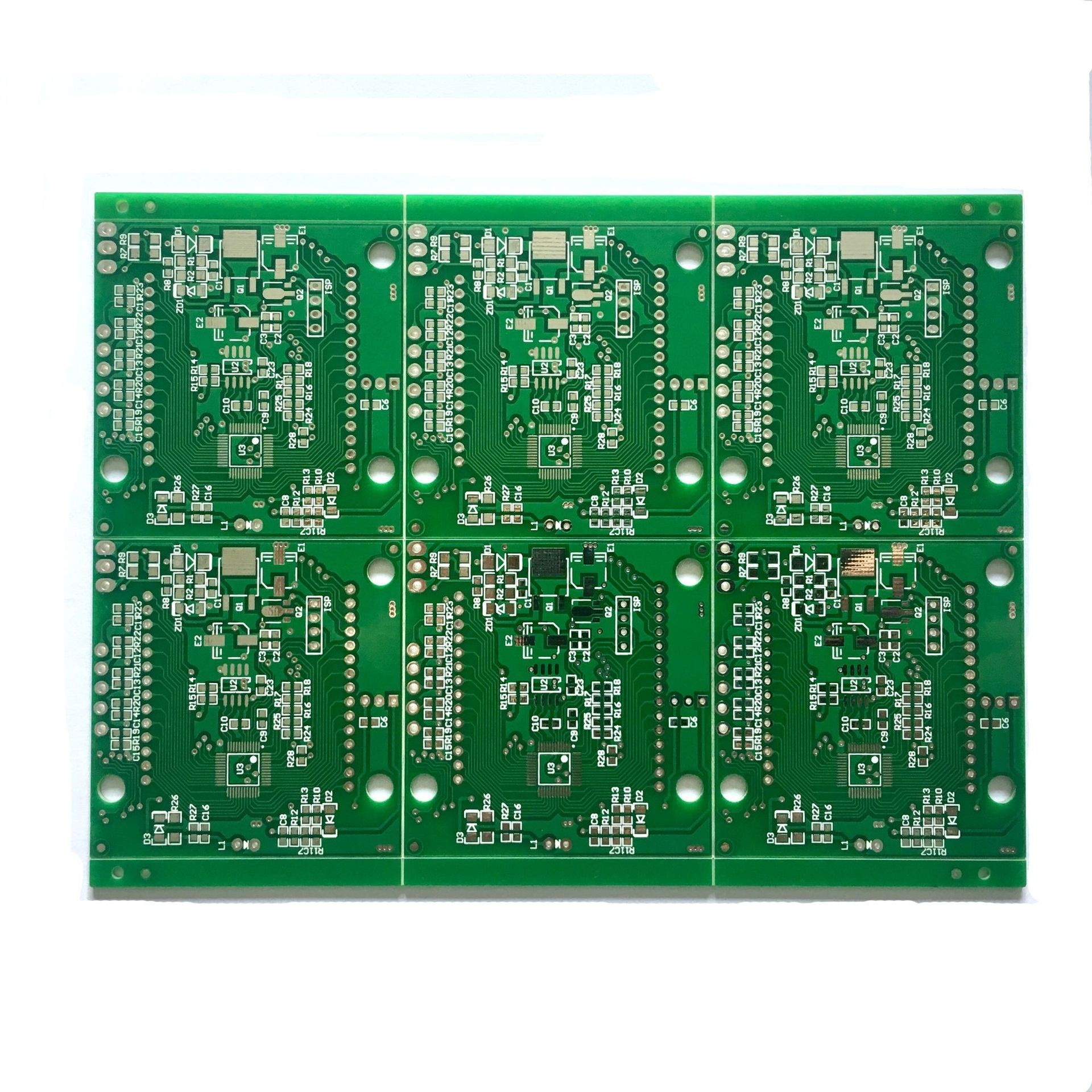

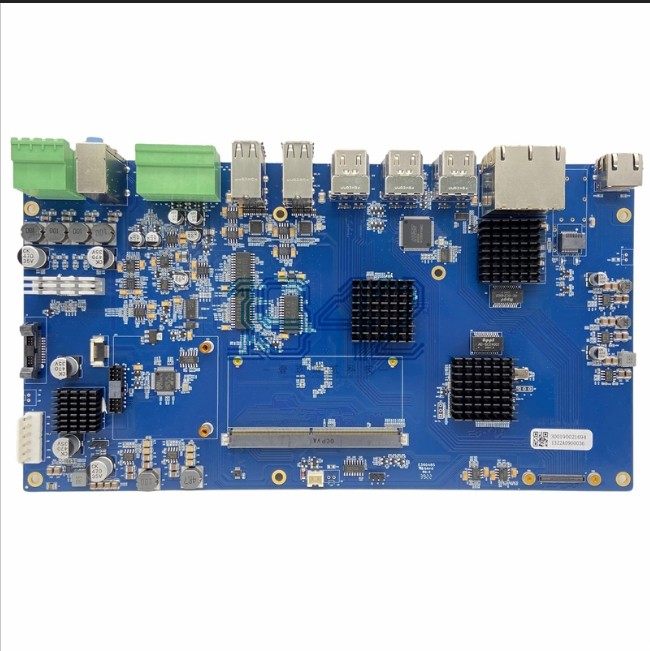

TAOXING Semi-Automatic Flat Screen Printer TX-4050T For PCB Boards and SMT Patch Solder Paste Printing

group nameSemi-Automatic Flat Screen Printing Machine

-

Min Order1 set

brand nameTAOXING Screen Printing Machines Manufacturer

modelTX-4050T

payment methodT/T

-

update timeTue, 05 Nov 2024 02:23:47 GMT

Packging & Delivery

Weight200.00kg / set

Min Order1 set

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union