Fully Automatic NdFeB Magnet Printing Machine and UV light Curing Equipment

group nameAutomatic Flat Screen Printing Machine

-

Min Order1 set

brand nameTAOXING Screen Printing Machines Manufacturer

modelTX-SF3045HDU

payment methodT/T

-

update timeFri, 01 Nov 2024 09:23:18 GMT

Paramtents

Fixture area 250x460mm

Max printing area 250 x 460mm

Maximum screen frame size 600x1000mm

Scraper/ink knife adjustment angle 0 ~ 45 ℃

Screen frame thickness 25~40mm

Table fine-tuning range ± 10mm

Height from the ground 850 ±50 mm

Washing height 220mm

Voltage/ Power AC380V/ 3KW

Table suction have

Air source pressure 0.5~0.7 Bar

Print thickness 1-50mm (servo adjustable)

Printing repeatability ±0.1mm

Machine size L2580xW1200xH1650mm

Packging & Delivery

Min Order1 set

Briefing

Detailed

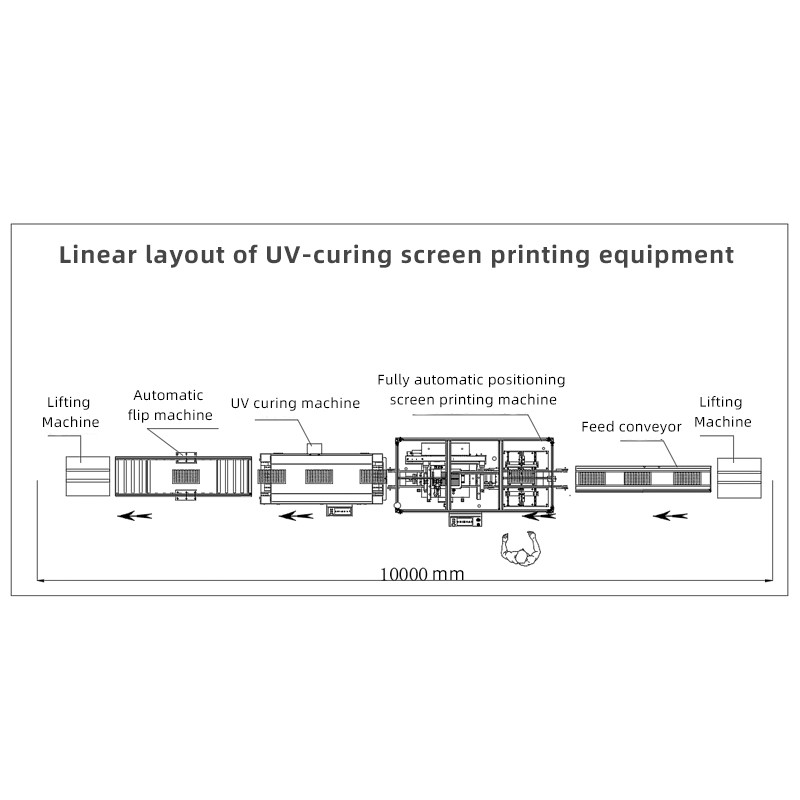

1. Overall layout design plan

2. Screen printing machine working process:

3.Main parameters of printing press

Main performance

4. UV Light curing dryer

5. Automatic turning machine: 1 set

6. Feeding rotary production line: 1 set

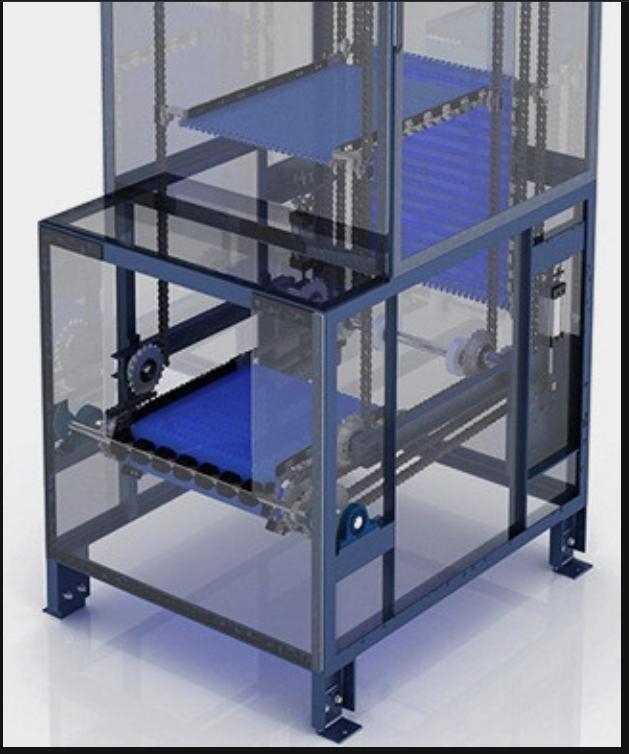

7. Vertical hoist: 2 sets

8. Machine maintenance

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo, Shenzhen, Yiwu

- Delivery clauses under the trade mode

- FOB, CFR, EXW

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union