The physical, chemical and biological statement of the material state stay unchanged. The damage to volatility composition and denaturalization nutrition ingredient under heating condition is lowed. The material after processing is porous and volume is almost the same as before processing. So due to large contact are, when the material is added with water, it can recover quickly and has longer storage life in sealed container.

The freeze dry machine can be widely used for developing and producing various heat sensitive biological products, such as vaccine, medicines, fruit vegetable vacuum packing, etc.

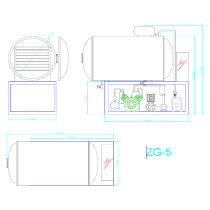

The freeze dry machine is of compact structure, full automatic control, easy to maintain and operate, with following advantages:

1. Vacuum state, the drying material quality is as good as frozen material.

2. PLC control with touchable human-computer operating interface, to realize real-time recording for multi-channel temperature data in drying processing and available for observation in curve form.

3. The shelf temperature control curve can be preset to realize the automatic sublimation.