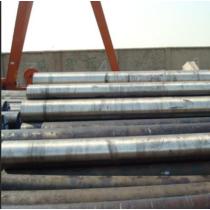

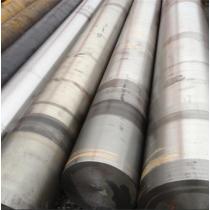

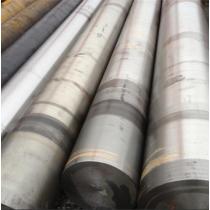

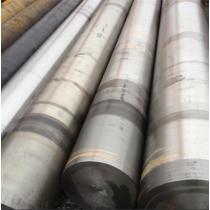

21CrMoV5-11 1.8070 21CrMoV5-7 1.7709 Hot Forged Alloy Steel Round Bar

group nameRound Forgings

-

Min Order1 metric ton

brand namefushun

model21CrMoV5-11 1.8070 21CrMoV5-7 1.7709

payment methodL/C, D/A, D/P, T/T

-

update timeMon, 25 May 2020 14:01:00 GMT

Paramtents

Standard EN 10269

Applications steam turbines, rotor blades, shaft forgings, etc

Heat treatment Normalized,Quenching and Tmenpering

Surface condition Black or bright surface

Packging & Delivery

Min Order1 metric ton

Briefing

Detailed

You need a product

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A