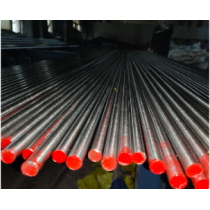

102Cr6 1.2067 ШХ15 Cold Work Tool Steel Round Bar

group nameTool Steel Bars

-

Min Order1 piece

brand namefushun

model102Cr6 1.2067 ШХ15

payment methodT/T, L/C, D/P D/A

-

update timeThu, 26 May 2022 14:08:31 GMT

Paramtents

Delivery Condition +N or +A or +QT

Surface Condition black or turned or polished

Packging & Delivery

Min Order1 piece

Briefing

Detailed

102Cr6 1.2067 ШХ15 Cold Work Tool Steel Round Bar

Grade :102Cr6

Number: 1.2067

Classification:Alloy cold-work tool steel

Our supply size :

Diameter : 80 to 600 mm ;

Length : 1000 to 9000 mm ;

Our capacity :

Delivery condition : Normalized, or Annealed, or Quenched and Tempered ;

Surface condition : Grounded, or Turned, or Polished

Our advantage :

1. High Quality, Reasonable Price

2. Over 40 Years Experience

3. ISO NQA Certificated Factory

4. Worldwide shipping

5. Emergency Orders and Fast Delivery

Equivalent grades of steel 102Cr6 (1.2067)

EU | USA | Germany | Japan | France | England | Italy | China | Sweden | Poland | Russia |

EN | - | DIN,WNr | JIS | AFNOR | BS | UNI | GB | SS | PN | GOST |

102Cr6 | 52100 | 100Cr6 | SUJ2 | 100Cr6 | 534A99 | 100Cr6 | Cr2 | 2258 | LH15 | KH |

100Cr6RR | 535A99 | GCr15 | ShKh15 |

Standard

EN 10132-4: 2000 Cold rolled narrow steel strip for heat treatment. Technical delivery conditions. Spring steels and other applications

EN ISO 4957: 2000 Tool steels

Chemical composition % of steel 102Cr6 (1.2067): EN 10132-4-2000

C | Si | Mn | Ni | P | S | Cr | Mo |

0.95 - 1.1 | 0.15 - 0.35 | 0.2 - 0.4 | max 0.4 | max 0.025 | max 0.025 | 1.35 - 1.6 | max 0.1 |

Heat treatment of 102Cr6, 1.2067 steel:

Softening annealing at 780 - 810 ℃ with furnace cooling to 550 - 600 ℃ at 10-20 ℃ hourly with subsequent air or isothermal cooling at 680 - 720 ℃ Tempering at 830 - 870 ℃ with cooling in oil or water at 820 - 850 ℃ Tempering at 150 - 170 ℃ in the air

Mechanical properties of steel 102Cr6 (1.2067)

Nominal thickness (mm): | 0.3 - 3 |

Rm - Tensile strength (MPa) (+A) | 750 |

Nominal thickness (mm): | 0.3 - 3 |

Rm - Tensile strength (MPa) (+QT) | 1300-2100 |

Nominal thickness(mm): | 0.3 - 3 |

Rp0.2 0.2% proof strength (MPa) (+A) | 590 |

Nominal thickness (mm): | 0.3 - 3 |

A - Min. elongation Lo = 80 mm (%) (+A) | 11 |

Vickers hardness ( HV): (+A) | 235 |

Vickers hardness ( HV): (+QT) | 405 - 630 |

Brinell hardness (HB): (+A) | 223 |

102Cr6 as a differently graded flat or round grade is used for the manufacture of cold forming dies and stamps, file cutters, wood and paper cutting knives, taps, scrapers, or broaches.

PRODUCT DESCRIPTION

The alloy is usually produced by EAF /VD /LF followed by electroslag refining (ESR) if necessary for special purpose.

Bars and, where applicable, forgings are subjected to ultrasonic examination based on the different level according to the buyers' requirements.

Bars are usually supplied bright in the softened condition.

Final heat treatment - heat treatment / QT

Mill′s test certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Smelting Option

1 EAF: Electric Arc Furnace

2 EAF+LF+VD: Refined-smelting and vacuum degassing

3 EAF+ESR: Electro Slag Remelting

4 EAF+PESR: protective atmosphere Electro Slag Remelting

5 VIM+PESR: Vacuum induction melting

Forming Option

1 Hot rolling process

2 Hot Forging: Electro-hydraulic; High-speed-hydraulic; Oil-hydraulic; Precision-forging

Heat-treatment Option

1 +A: Annealed (full/soft/spheroidizing)

2 +N: Normalized

3 +NT: Normalized and tempered

4 +QT: Quenched and tempered (water/oil)

Surface Option

1 Black Surface

2 Grounded: Bright but rough ; Not precision

3 Machining for plate: Bright and precision; Little turning scar

4 Peeled/Turned: Bright and precision; Little turning scar

5 Polished: Very Bright and precision size; Not turning scar

Other Services

1 Cutting: Small pieces

2 CNC Machine: Produce as your drawing

3 Package: Bare/Nylon/Canvas/Wooden

4 Payment:T/T, L/C, O/A(request credit)

5 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

You need a product

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A