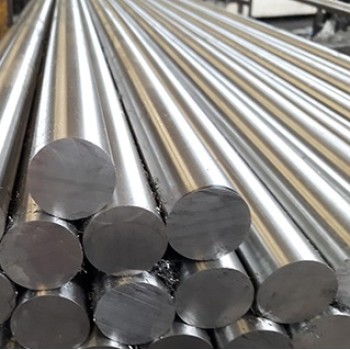

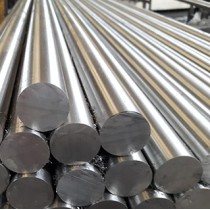

Inconel C276 N10276 2.4819 Corrosion Resistance Alloy Bar

group nameNickel Alloy Bar

-

Min Order1 piece

brand namefushun

modelInconel C276 N10276 2.4819

payment methodL/C, T/T

-

update timeMon, 27 Feb 2023 10:29:46 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Inconel C276 N10276 2.4819 Corrosion Resistance Alloy

C276 (UNS N10276) is a cold hardened nickel-based alloy intended for the most extreme well conditions up to 450°F.

In addition to its exceptional corrosion resistance under the most severe conditions, higher strengths may be achieved with C276 than other nickel alloys. It is therefore used for downhole tubular components, packers, and other subsurface equipment under the most extreme environmental conditions found in high-pressure, high-temperature (HPHT) wells, saltwater Injection wells, and Acid Gas Injection (AGI) wells. However, all environmental factors, including H2S, CO2 , temperature, pH, and chloride concentration, should be considered before final material selection.

The alloy is classified in MR0175/ISO15156 as a type 4e alloy, with no restrictions to a partial pressure of H2S below 400°F and resistant to 1000 psi H2S at 450°F.

Hastelloy C276 alloy (UNS N10276) was the first wrought, nickel-chromium- molybdenum material to alleviate concerns over welding (by virtue of extremely low carbon and silicon contents). As such, it was widely accepted in the chemical process and associated industries,

ALSO KNOWN AS

• C-276

• SMC276®

• INCONEL® Alloy C-276

• Hastelloy® C-276

• W.Nr. 2.4819

Applications

Typical chemical process industry (CPI) applications include reactors, heat exchangers, and columns, marine hardware, Chemical processing components Agrichemical and petrochemical production.

CHEMICAL COMPOSITION

C | Cr | Ni | Fe | Mn | Si | Mo | Co | P | S | V | W |

≤ 0.02 | 14.5 - 16.5 | BAL | 4 - 7 | ≤ 1 | ≤ 0.08 | 15 - 17 | ≤ 2.5 | ≤ 0.03 | ≤ 0.03 | ≤ 0.35 | 3 - 4.5 |

MANUFACTURING PROCESS

PROCESS | DESCRIPTION |

Steel Making | Made by electric furnace process or blast furnace followed by Vacuum Oxygen Decarburization (VOD) process or Argon Oxygen Decarburization (AOD) Process |

Pipe Making | Manufactured by traditional tube manufacturing processes, High strength tubulars should be furnished in cold worked condition |

Heat Treatment | Solution Annealing Process before final cold drawing |

API 5CRA / ISO 13680 Group 2 Category 15-60-16

Grade | Yield | Tensile | Elongation | Hardness | NACE MR0175/ISO 15156 | ||

min | max | min | min | max | |||

110 | 110 | 140 | 125 | 11 | 35 | Table A.14 | No limit ≤ 400°F, |

125 | 125 | 150 | 130 | 10 | 37 | ||

140 | 140 | 160 | 145 | 9 | 38 | 140 Grade not recommended for sour service | |

*Non-standard mechanical properties and grades are made available upon agreement. | |||||||

TYPICAL PHYSICAL PROPERTIES

70°F | 200°F | 400°F | ||

Density | lbs/in3 | 0.32 | ||

Thermal Expansion | X10-6/°F | 6 | 6.2 | 6.7 |

Elastic Modulus | psi x 106 | 29.8 | 29 | 28.3 |

Poisson Ratio | 0.3 | |||

Thermal Conductivity | Btu/ft h °F | 5.9 | 6.4 | 7.5 |

Specific Heat | Btu/lb °F | 0.1 | 0.1 | 0.1 |

Specification

HASTELLOY C-276 | ASTM | ASME | DIN |

Plate sheet and Strip | B575 / B906 | SB575 / SB906 | 17750 |

Seamless, Pipe and Tubing | B622 / B829 | SB622 / SB829 | 17751 |

Welded Pipe and Tubing | B626 / B751 B619 / B775 | SB626 / SB751 SB619 / SB775 | 17751 |

Rod, Bar and Forgings | B462 / B564 / B574 | SB564 / SB574 | 17752 / 17753 / 17754 |

Impact Strength

Type of Test | Test Temperature | Form | Thickness | Impact Strength | ||

in | mm | ft.lbf | J | |||

Charpy V-Notch | RT | Plate | 0.394 | 10 | 348 | 472 |

Charpy V-Notch | RT | Plate | 0.472 | 12 | 351 | 476 |

Hardness

Form | Hardness, HRBW | Typical ASTM Grain Size |

Sheet | 88 | 3.5 - 6 |

Plate | 88 | 1 - 5 |

Bar | 86 | 1 - 5 |

Welding and Fabrication

HASTELLOY C-276 alloy is very amenable to the Gas Metal Arc GMA/MIG), Gas Tungsten Arc (GTA/TIG), and Shielded Metal Arc (SMA/Stick) welding processes. Matching filler metals (i.e. solid wires and coated electrodes) are available for these processes, and welding guidelines are given in the “Welding and Fabrication” brochure.

HASTELLOY C-276 alloy can be hot forged, hot rolled, hot upset, hot extruded, and hot formed. However, it is more sensitive to strain and strain rates than the austenitic stainless steels, and the hot working temperature range is quite narrow. While cold work does not usually affect the resistance of HASTELLOY® C-276 alloy to general corrosion, and to chloride-induced pitting and crevice attack, it can affect resistance to stress corrosion cracking. For optimum corrosion performance, therefore, the re-annealing of cold worked parts (following an outer fiber elongation of 7% or more) is important.

You need a product

Related Searches

You May Like

6YRS FUSHUN Metals

- Nearest port for product export

- Tianjin, Qingdao, Shanghai, Huangshi

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, CPT, DDP, DDU, DAF

- Acceptable payment methods

- T/T, L/C, D/P D/A