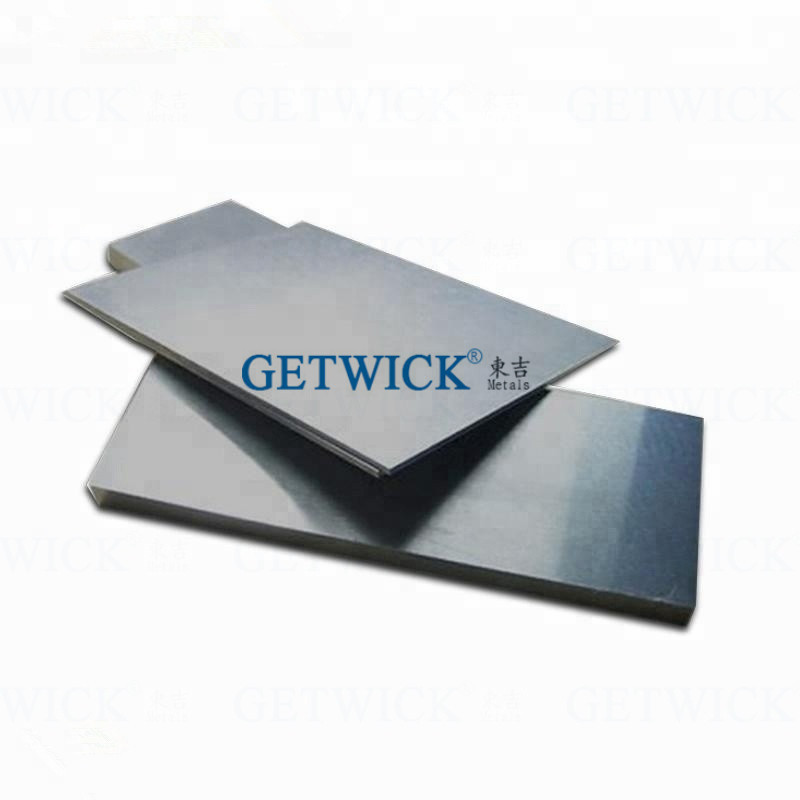

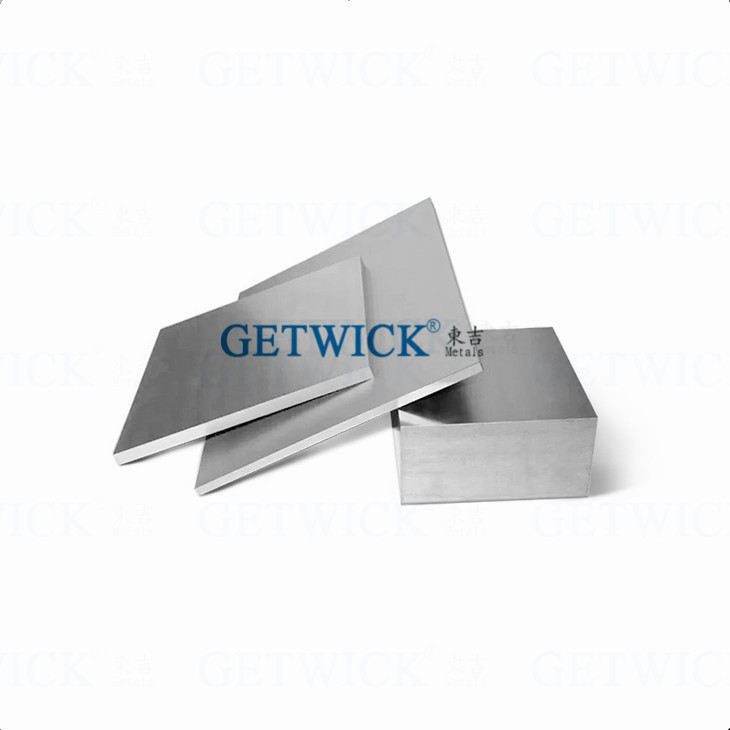

Selling 99.95% Rolling Molybdenum Plate and Sheet with Good Price

group nameMOLYBDENUM PLATE

-

Min Order1 kilogram

brand nameGETWICK 東吉

model364, MLa

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeMon, 08 Apr 2019 16:01:59 GMT

Paramtents

Key product Mo-1 new type Molybdenum sheet price

Material Molybdenum Lanthanated Alloy Sheet

Feature High temperature resistance

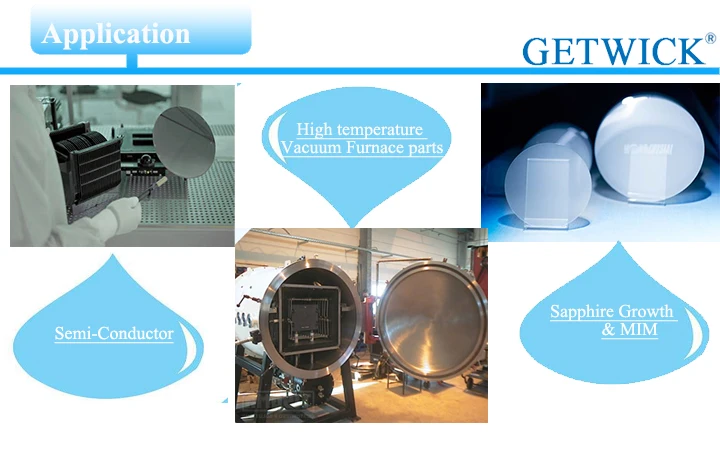

Application Vacuum furnace heatsheild

Standard ASTM B386

Grade 361, Mo1

Purity 99.95% Min

Working temperature 1700 - 1900

Advantage Factory supply price

Packging & Delivery

Min Order1 kilogram

Briefing

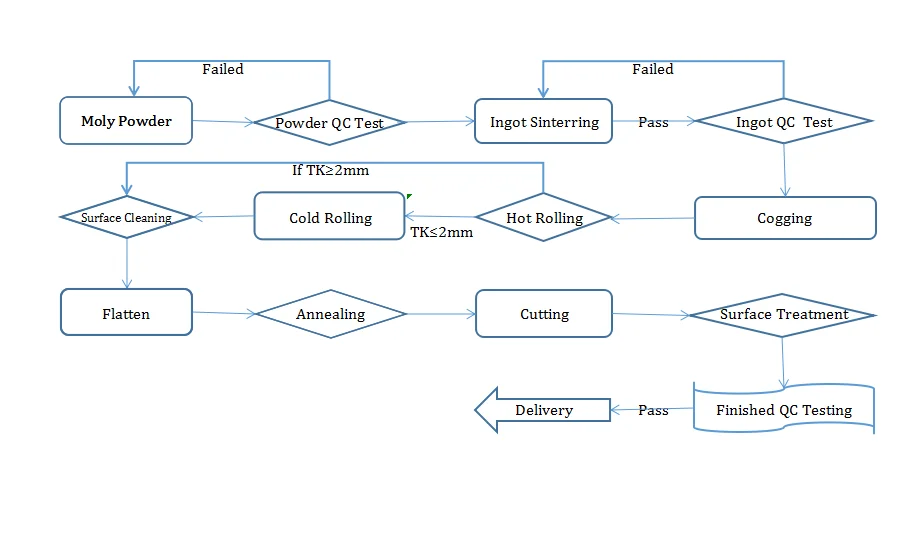

Alkali Bright Cold Rolling Molybdenum Plate

Hot-Rolled Molybdenum Sheet for Vacuum Furnace

Detailed

Selling 99.95% Rolling Molybdenum Plate and Sheet with Good Price

You need a product

You May Like

- Nearest port for product export

- Shanghai,, Guangzhou, Qingdao, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, Credit Card, PayPal, Westem Union, Cash, Escrow