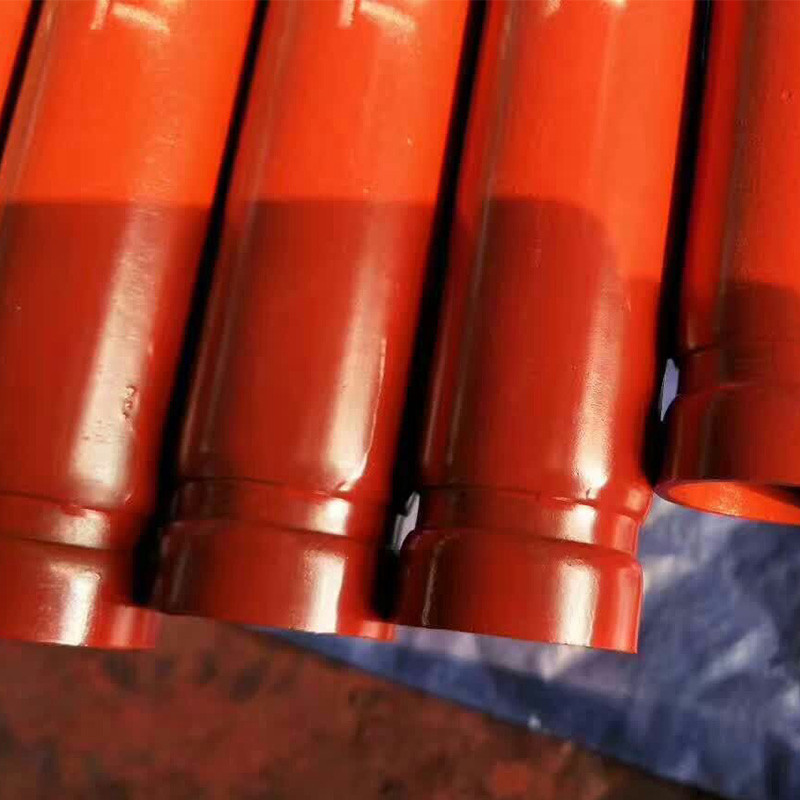

red painted Epoxy Sprinkler fire pipe with ul certificate

- US $850.00

5 - 25 ton

group nameGrooved End Steel Pipe

-

Min Order5 ton

brand nameYoufa Steel Pipe Manufacturer

payment methodL/C, Western Union, T/T, other payment by negonitation

-

update timeTue, 05 Nov 2024 14:43:35 GMT

Paramtents

Technic Standard ASTM A53 , ASTM A795

Pipe Length 5.8m, 6m, 6.4m, 7.3m, 19ft, 20ft, 21ft, 24ft

Other surface finished painted red color RAL3000 , Galvanized and then painted red color, black color painted, epoxy coated, anti-rust oiled , or bare no surface treatment

About surface finished the surface finished can be specified by customers

Packging & Delivery

Min Order5 ton

Briefing

Detailed

Fire Sprinkler Steel Pipe General Product Information

|

Commodity

|

Fire sprinkler ERW carbon steel pipes |

|

Usage | construction, building material, fire sprinkler steel pipeline | |

|

Size

|

1/2''-10'' (round hollow)

|

|

Wall thickness | 1.3mm-10mm | |

Length | 5.8m, 6m or cut into other length according to PI | |

Certificates international standard | ISO 9000-2001, UL certificate | |

Standards | ASTM A795, ASTM A53, GB/T3091, etc | |

|

Technique

|

Welded

|

|

Surface | Galvanized or Painted to prevent the rust | |

Pipe ends | Plain or threaded with sockets/coupling and plastic cap or grooved with caps | |

|

Packing

|

In bundles, or request.

|

|

Marking | As requested in PI, for example "UL LISTED YOUFA SCH10 / SCH40" | |

ASTM A795 ERW Carbon Steel Tube Standard Specifications Reference

NPS | DN | Outer Diameter(mm) | Schedule 10 | Schedule 40 | ||||

Wall Thickness (mm) |

Unit Weight (kg/m) | Test Pressure (kpa) | Wall Thickness

(mm) | Unit Weight

(kg/m) | Test Pressure (kpa) | |||

|

1/2"

|

15

|

21.3 |

-

|

- | - | 2.77 | 1.27 | 4800 |

|

3/4"

|

20

|

26.7 | 2.11 |

1.28 | 4800 | 2.87 | 1.69 | 4800 |

1" | 25 | 33.4 | 2.77 | 2.09 | 4800 | 3.38 | 2.50 | 4800 |

1-1/4" | 32 | 42.2 | 2.77 | 2.69 | 6900 | 3.56 | 3.39 | 6900 |

1-1/2" | 40 | 48.3 | 2.77 | 3.11 | 6900 | 3.68 | 4.05 | 6900 |

2" | 50 | 60.3 | 2.77 | 3.93 | 6900 | 3.91 | 5.45 | 6900 |

2-1/2" | 65 | 73 | 3.05 | 5.26 | 6900 | 5.16 | 8.64 | 6900 |

3" | 80 | 88.9 | 3.05 | 6.46 | 6900 | 5.49 | 11.29 | 6900 |

4" | 100 | 114.3 | 3.05 | 8.37 | 8300 | 6.02 | 16.09 | 8300 |

5" | 125 | 141.3 | 3.40 | 11.58 | 8300 | 6.55 | 21.79 | 8300 |

6" | 150 | 168.3 | 3.40 | 13.85 | 6900 | 7.11 | 28.29 | 8300 |

8" | 200 | 219.1 | 4.78 | 25.26 | 5500 | sch30 7.04 | 36.82 | 8300 |

10" | 250 | 273.1 | 4.78 | 31.62 | 4800 | sch30 7.8 | 51.05 | 6900 |

Pls don't hesitate to contact us if you need other sizes. | ||||||||

ERW Carbon Steel Fire Sprinkler Pipes Surface and Pipe Ends

ASTM A795 Fire Sprinkler Pipes Test and Quality Control

Chemical Composition |

for Type E (electric-resistance-welded pipe)

|

|||

|

C, Max, %

|

Mn, Max, % |

P, Max, %

|

S, Max, %

|

|

|

Grade A

|

0.25

|

0.95 |

0.035

|

0.035

|

|

Grade B

|

0.30

|

1.20 |

0.035

|

0.035

|

Mechanical Properties |

for thickness sch10 and sch40

|

||

|

Tensile strength, min [MPa]

|

Yield strength, min [MPa]

|

Elongation, min, %

|

|

|

Grade A

|

330

|

205

|

24

|

|

Grade B

|

415

|

240

|

24

|

You need a product

You May Like

- Nearest port for product export

- Tianjin Port, Shanghai Port,etc.

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A