Cast & Sintered Alnico Magnets

group nameAlnico Magnets

-

Min Order1 piece

brand nameCINFER Magnet

payment methodT/T, L/C

-

update timeThu, 06 Dec 2018 13:35:03 GMT

Paramtents

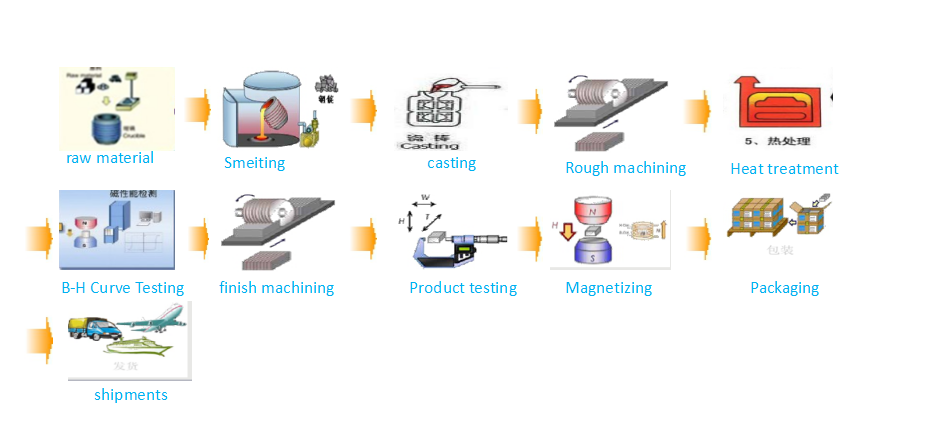

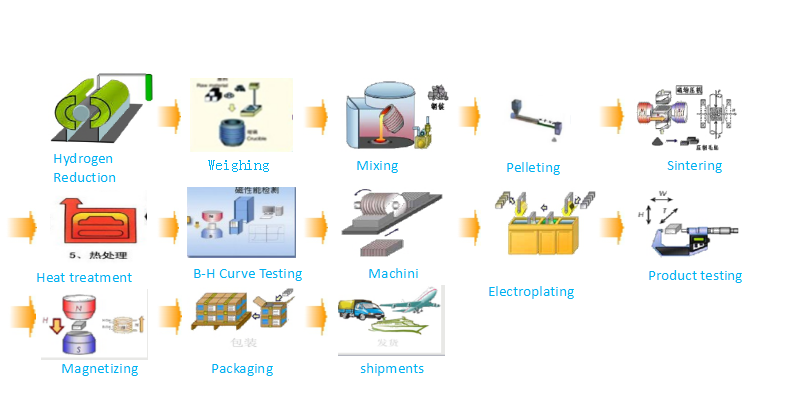

Material Cast AlNiCo ,Sintered AlNiCo

Shape Any shape Can be customized

Coating Ni, Ni-Cu-Ni, Electroless Nickel, Zinc, Colored Zinc, Epoxy

Magnetized direction Axially or Diametrical Magnetized, but Thickness, Multipoles and Radial magnetization are also available

Certificate ISO/TS 16949, ISO9001, ISO14001, RoHS, REACH

Packing Standard sea or air packing, such as carton, wooden box, pallet etc.

Packging & Delivery

Min Order1 piece

Briefing

Detailed

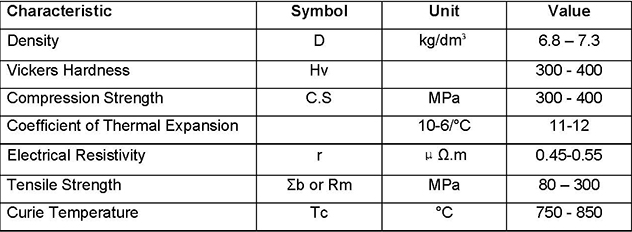

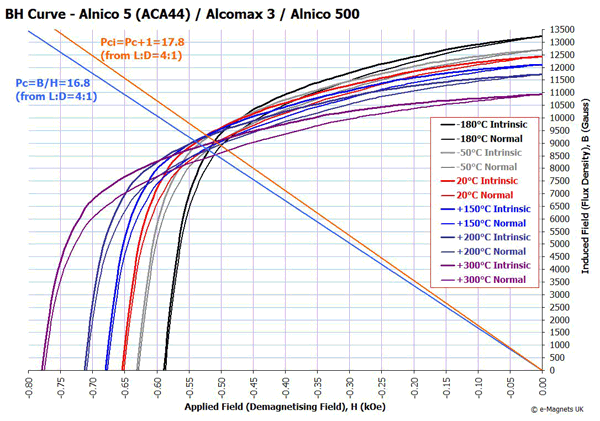

Alnico is an acronym referring to a family of iron alloys which in addition to iron are composed primarily of aluminium (Al), nickel (Ni) and cobalt (Co), hence al-ni-co. They also include copper, and sometimes titanium. Alnico alloys are ferromagnetic, with a high coercivity (resistance to loss of magnetism) and are used to make permanent magnets. Before the development of rare earth magnets in the 1970s, they were the strongest type of magnet. Other trade names for alloys in this family are: Alni, Alcomax, Hycomax, Columax, and Ticonal.

The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe. The development of alnico began in 1931, when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminum had a coercivity of 400 oersted (Oe; 32 kA/m), double that of the best magnet steels of the time.

AlNiCo can be divided to cast AlNiCo and sintered AlNiCo. When compared with cast AlNiCo, sintered AlNiCo perform with lower magnetic properties but better mechanical properties. AlNiCo are brittle and hard, not suitable for traditional maching processes except grinding processing.

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C