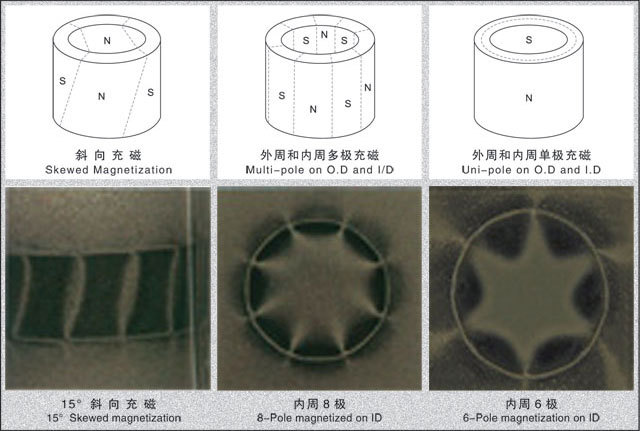

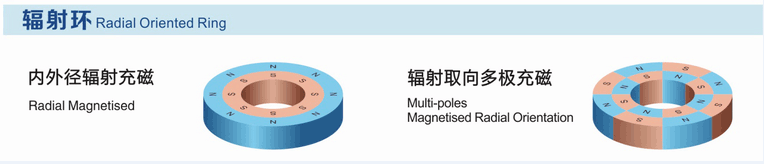

Radial ring is a whole radial oriented ring magnet.It can be magnetized by 3ways:Uni-pole on O.D and I.D、Multi-pole on O.D and I.D、Skewed Magnetization The ring is mainly used as induction magnet for motors.It imporves motors performance and effciency,and also radial ring is the market trends of motor.

Advantage of Radially oriented sintered NdFeB ring

1.Assenbly easiy,installation of one rings than glusing arcs into place,simple and quick.and good performance of dynamic blance.

2.Be kin to sine wave.

3.Radial sintering assures no "weak spots"

4.Magnets are multi-poled ring does not compromise the magnetic properties.

5.Be straight or skewed magnetized after assembly,provide a possibility of unique design by truly different magnetic circuit.

6.Radial ring direftly determines the shape tolerance,the tolerance of outer and inner diameter can achieve±0.04mm,and has the good coaxiality and verticality.

Radically Oriented Sintered NdFeB Ring & Arc Magnetic Property Table

材料 Grade | 剩 磁 Br Residual Induction | 矫顽力Hcb Coercive Force | 内禀矫顽力 Hcj Intrinsic Coercive Force | 最大磁能积 (BH)max Maximum Energy Product | 密度D Density | 工作温度Working Temp (L/D=0.7) | 温度系数 Temp Coefficient | 可逆磁导率Recoil Magnetic Permeability | 居里温度Curie Temp | 硬度 Hardness |

α Br | β Hcj | μrec | ℃ | (HV) |

KG | T | KOe | KA/m | kOe | KA/m | MGOe | KJ/m3 | g/cm3 | ℃ | % .℃-1 | | | |

| min | max | min | max | min | min | min | min | min | max | min | max | min | max | max | max | min | min | max | min | max | | min | ma x |

N35R | 11.8 | 12.9 | 1.18 | 1.29 | 9.5 | 756 | 11 | 876 | 31 | 37 | 247 | 295 | 7.45 | 7.6 | 80 | -0.11 | -0.12 | 0.65 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

N38R | 12 | 13.2 | 1.20 | 1.32 | 9.6 | 764 | 11 | 876 | 32 | 40 | 255 | 318 | 7.45 | 7.6 | 80 | -0.11 | -0.12 | 0.6 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

N42R | 12.2 | 13.5 | 1.22 | 1.35 | 9.7 | 772 | 11 | 876 | 34 | 42 | 271 | 334 | 7.45 | 7.6 | 80 | -0.11 | -0.12 | 0.6 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

N35MR | 11.8 | 12.9 | 1.18 | 1.29 | 9.5 | 756 | 12.5 | 995 | 31 | 37 | 247 | 295 | 7.45 | 7.6 | 100 | -0.11 | -0.12 | 0.6 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

N38MR | 12 | 13.2 | 1.20 | 1.32 | 9.6 | 764 | 12.5 | 995 | 32 | 40 | 255 | 318 | 7.45 | 7.6 | 100 | -0.11 | -0.12 | 0.6 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

N42MR | 12.2 | 13.5 | 1.22 | 1.35 | 9.7 | 772 | 12.5 | 995 | 34 | 42 | 271 | 334 | 7.45 | 7.6 | 100 | -0.11 | -0.12 | 0.6 | 0.65 | 1.05 | 1.1 | 310 | 500 | 600 |

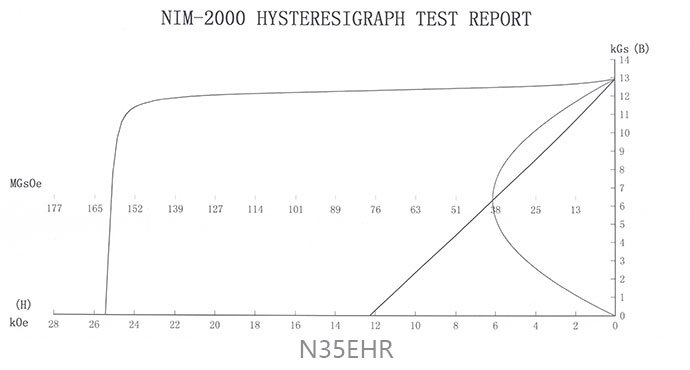

N35HR | 11.8 | 12.9 | 1.18 | 1.29 | 9.6 | 764 | 14 | 1114 | 31 | 37 | 247 | 295 | 7.45 | 7.6 | 120 | -0.1 | -0.11 | 0.58 | 0.62 | 1.05 | 1.1 | 320 | 500 | 600 |

N38HR | 12 | 13.2 | 1.20 | 1.32 | 9.7 | 772 | 14 | 1114 | 32 | 40 | 255 | 318 | 7.45 | 7.6 | 120 | -0.1 | -0.11 | 0.58 | 0.62 | 1.05 | 1.1 | 320 | 500 | 600 |

N40HR | 12.1 | 13.3 | 1.21 | 1.33 | 9.7 | 772 | 14 | 1114 | 33 | 41 | 263 | 326 | 7.45 | 7.6 | 120 | -0.1 | -0.11 | 0.58 | 0.62 | 1.05 | 1.1 | 320 | 500 | 600 |

N42HR | 12.2 | 13.5 | 1.22 | 1.35 | 9.8 | 780 | 14 | 1114 | 34 | 42 | 271 | 334 | 7.5 | 7.6 | 120 | -0.1 | -0.11 | 0.58 | 0.62 | 1.05 | 1.1 | 320 | 500 | 600 |

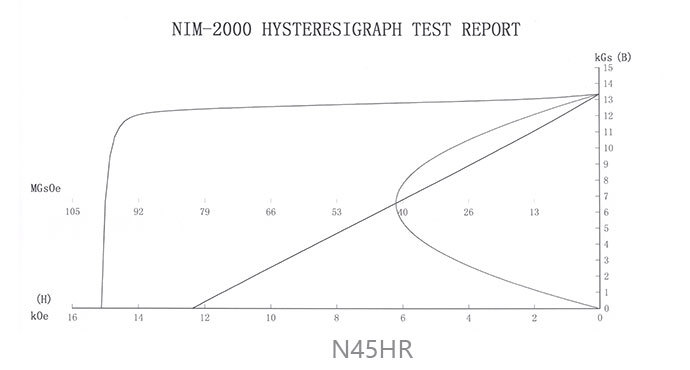

N45HR | 12.5 | 13.9 | 1.25 | 1.39 | 9.9 | 788 | 14 | 1114 | 36 | 45 | 287 | 358 | 7.5 | 7.6 | 120 | -0.1 | -0.11 | 0.58 | 0.62 | 1.05 | 1.1 | 320 | 500 | 600 |

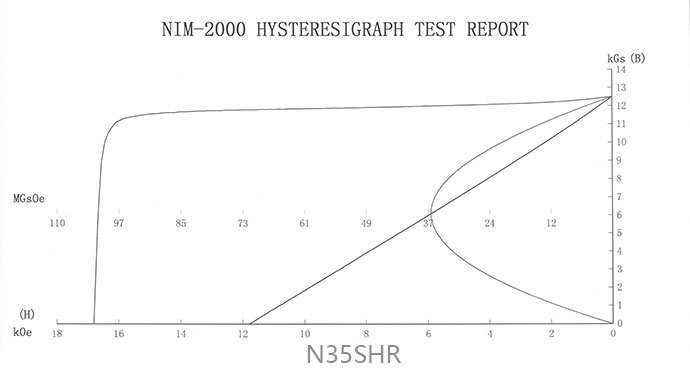

N-35SH | 11.8 | 12.9 | 1.18 | 1.29 | 9.7 | 772 | 16 | 1274 | 31 | 37 | 247 | 295 | 7.45 | 7.6 | 150 | -0.1 | -0.11 | 0.55 | 0.6 | 1.05 | 1.1 | 330 | 500 | 600 |

N-38SH | 12 | 13.2 | 1.20 | 1.32 | 9.8 | 780 | 16 | 1274 | 32 | 40 | 255 | 318 | 7.45 | 7.6 | 150 | -0.1 | -0.11 | 0.55 | 0.6 | 1.05 | 1.1 | 330 | 500 | 600 |

N-40SH | 12.1 | 13.3 | 1.21 | 1.33 | 9.8 | 780 | 16 | 1274 | 33 | 41 | 263 | 326 | 7.45 | 7.6 | 150 | -0.1 | -0.11 | 0.55 | 0.6 | 1.05 | 1.1 | 330 | 500 | 600 |

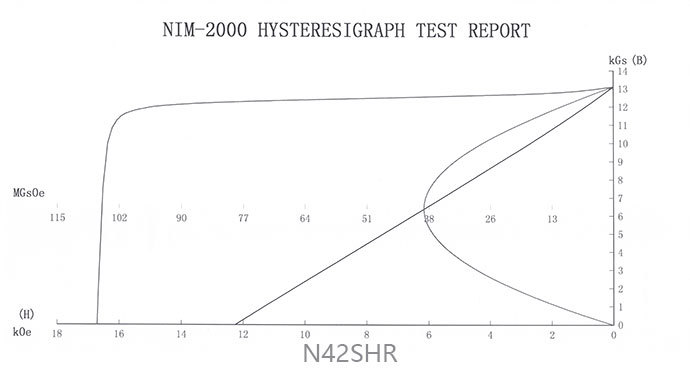

N-42SH | 12.2 | 13.5 | 1.22 | 1.35 | 10 | 796 | 16 | 1274 | 34 | 42 | 271 | 334 | 7.5 | 7.6 | 150 | -0.1 | -0.11 | 0.55 | 0.6 | 1.05 | 1.1 | 320 | 500 | 600 |

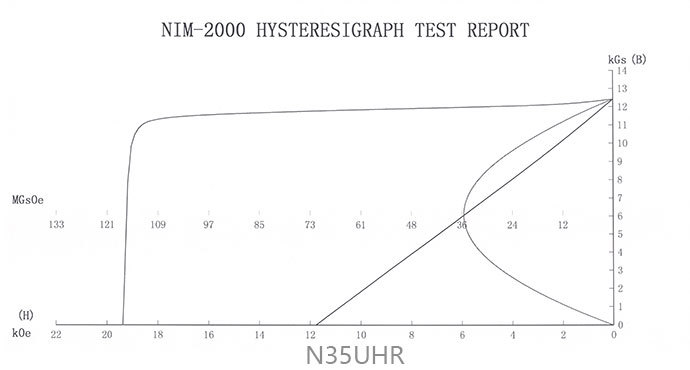

N-35UH | 11.8 | 12.9 | 1.18 | 1.29 | 9.8 | 780 | 19 | 1512 | 31 | 37 | 247 | 295 | 7.45 | 7.6 | 180 | -0.08 | -0.1 | 0.5 | 0.55 | 1.05 | 1.1 | 340 | 500 | 600 |

N-38UH | 12 | 13.2 | 1.20 | 1.32 | 10 | 796 | 19 | 1512 | 32 | 40 | 255 | 318 | 7.45 | 7.6 | 180 | -0.08 | -0.1 | 0.5 | 0.55 | 1.05 | 1.1 | 340 | 500 | 600 |