Custom Lightweight High Strength Plastic Polypropylene PP bubble board

group namePolypropylene (PP) Bubble Board

-

Min Order100 piece

brand namePolyreflex

modelPR-HO

payment methodL/C

-

update timeFri, 08 Nov 2024 06:33:14 GMT

Paramtents

Brand Polyreflex Polypropylene PP bubble board

Provided Service Die-cutting, CNC Engraveing,Sealing, Bending, Welding, Printing,Attaching Spunbond…

Custom Work Color, Width, Length, Size, Weight, Packing, Processing

Certificate RoSH, REACH, V0-V2 @UL94, No Lead, No Formaldehyde Content.

Main Application floor protection, side/back/roof panel for auto...

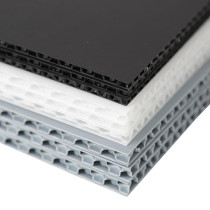

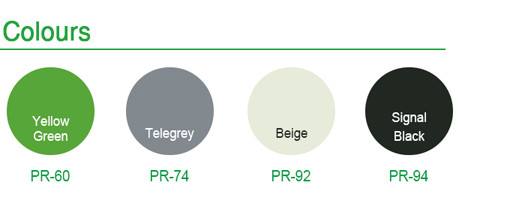

Main Colors black, dark grey, light grey, etc.

Update Time 2019-09-12

Packging & Delivery

Min Order100 piece

Briefing

provide any custom work, like color, size, cut, seal

Detailed

High impact

Flame retardant

Low VOC emission

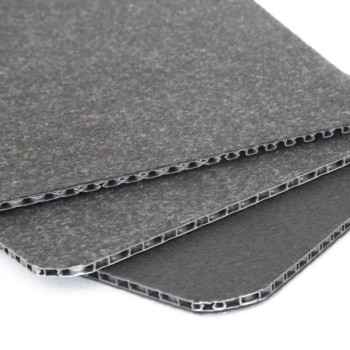

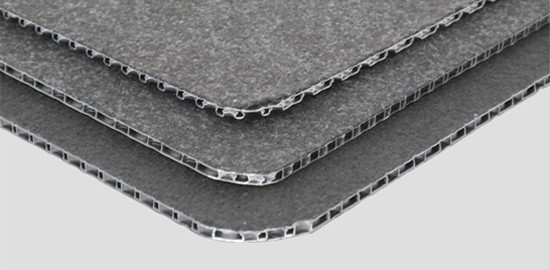

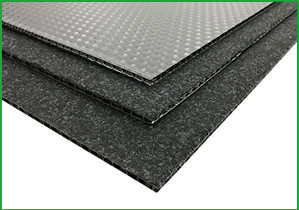

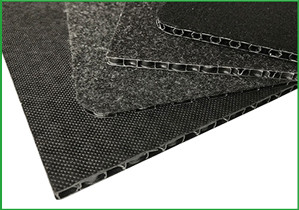

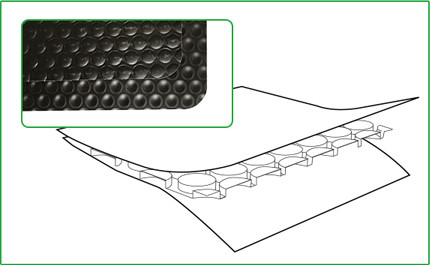

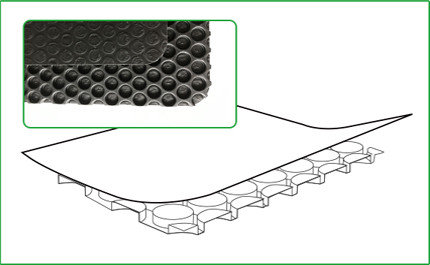

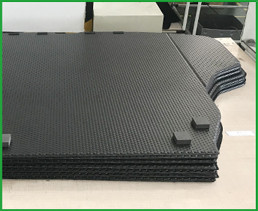

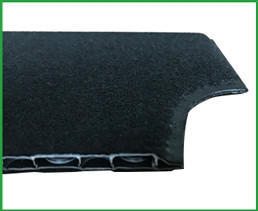

with a honeycomb structure inside and one/two flat surfaces with bubble

finish. It is Environment friendly, Flame retardant and durable.

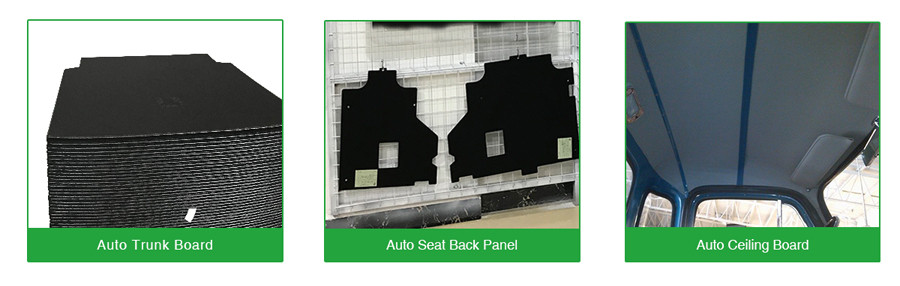

PP bubble board can be laminated with non-woven fabric. It is used as

spare wheel covers in the automobile luggage compartment, to achieve

the isolation function of spare tire and luggage compartment. It is also

used as luggage liner panel, seat back panel, side and roof panel of

mini-van, SUV, caravan etc.

It plays the role of body decoration, noise insulation, noise

reduction, load bearing and other.

- Light Weight – Approx. 50% Lighter Than Wood

- Numerous Options for Surface Finishing

- Dimension Stability and Waterproof

- Noise Insulation, Noise Reduction

- Excellent Compression Strength

- Corrosion and Rot Resistant

- Easy to Post Process

| Items | Modle | ||

| PP bubble board | PP bubble board with non-woven fabric | ||

| Thickness: | 3-11mm | 3-12mm | |

| Width: | Max. Width 1.5M. 900-1300mm are popular. Other width can be customized. | ||

| Size: | 1000x2000mm, 1200x2400mm, 1220x2440mm are standard. Other size can be customized. | ||

| Colour: | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. | Board | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. |

| Fabirc | Black, light black. | ||

| Weight: | 750-3800gsm. | Board | 750-3500gsm |

| Fabirc | 80-300gsm | ||

| Surface: | bubble surface | Single or double side for fabric lamination is available. | |

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal, Westem Union