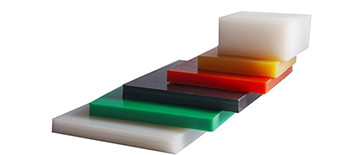

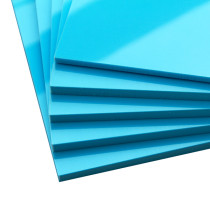

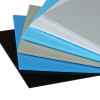

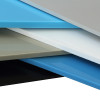

Professional Custom HDPE High Density Polyethylene Plastic Solid Sheet

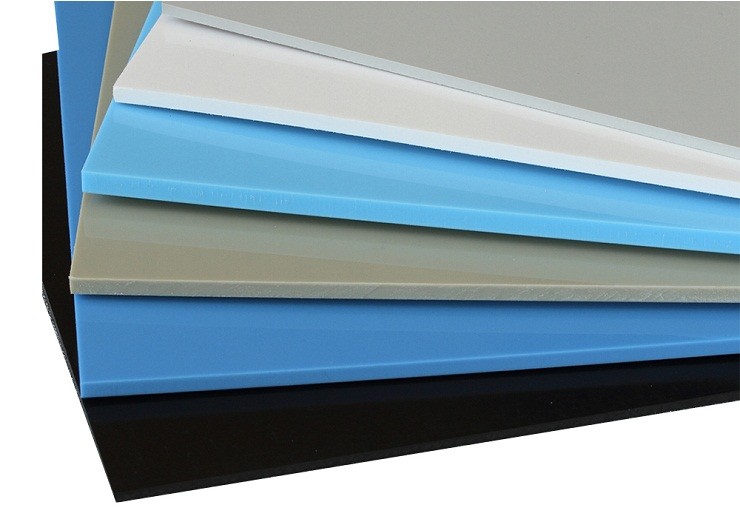

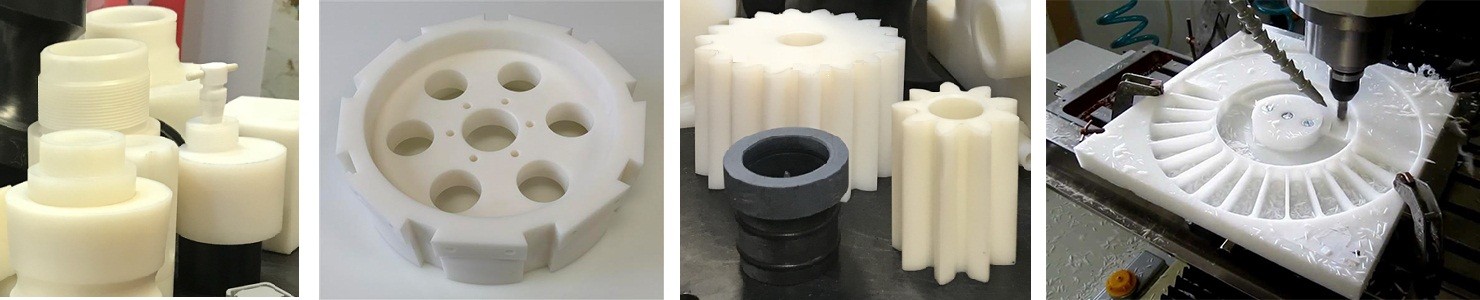

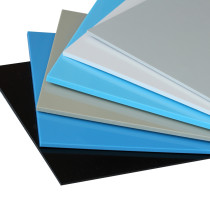

is a durable and versatile thermoplastic, which could offer high impact strength, high friction resistance, toughness with wide temperature range from -50ºC to 80ºC.

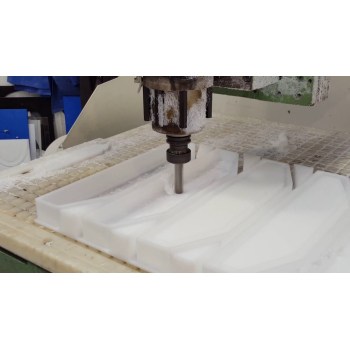

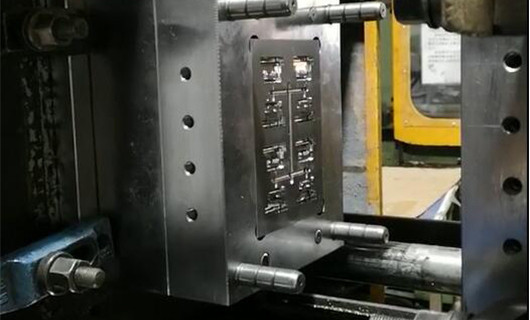

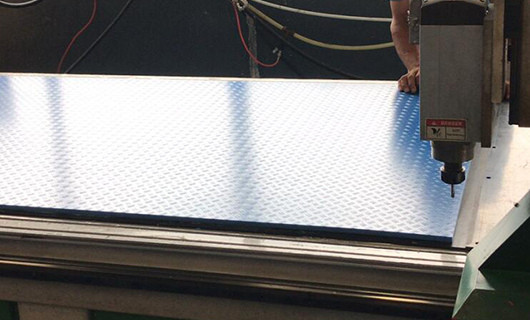

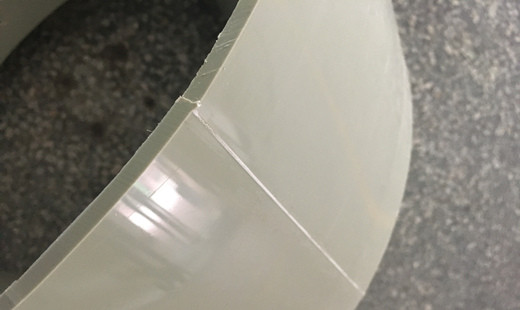

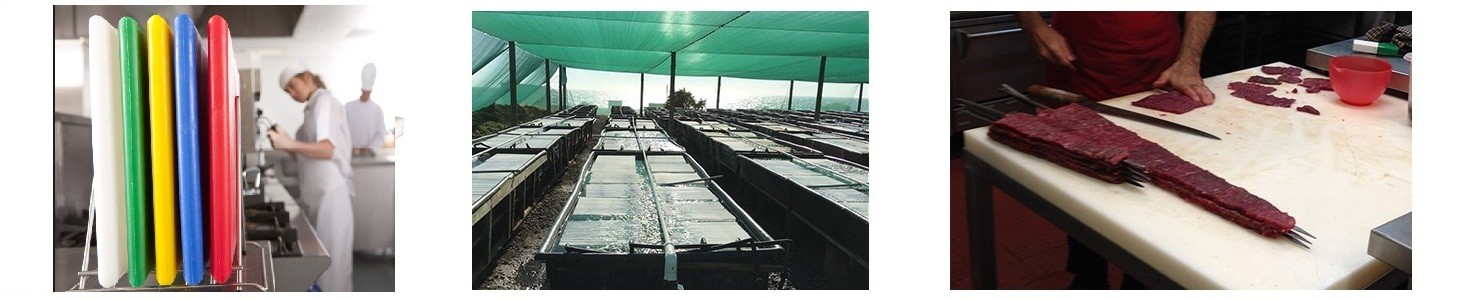

HDPE sheet has effective resistance to chemicals and good welding ability, so it can be easily welded into chemical tanks. HDPE is resistant to corrosion, mold, mildew, and rotting, this makes it extremely durable in various environments. At the same time HDPE board is widely used for light industry, it is an ideal material for replacing metal to make mechanical parts.

These are just a few of the popular HDPE applications. However, it can be useful in nearly any application where strength, moisture resistance, and chemical resistance are necessary.