steel structure building design

group nameSteel Structure Buildings

-

Min Order500 square meter

brand nameZYM steel structure building Manufacturer

modelZYM1

payment methodL/C, D/A, Western Union, T/T

-

update timeThu, 28 Dec 2023 02:55:32 GMT

Paramtents

Name Indonesia steel structure warehouse workshop

Key word Indonesia steel structure workshop with office

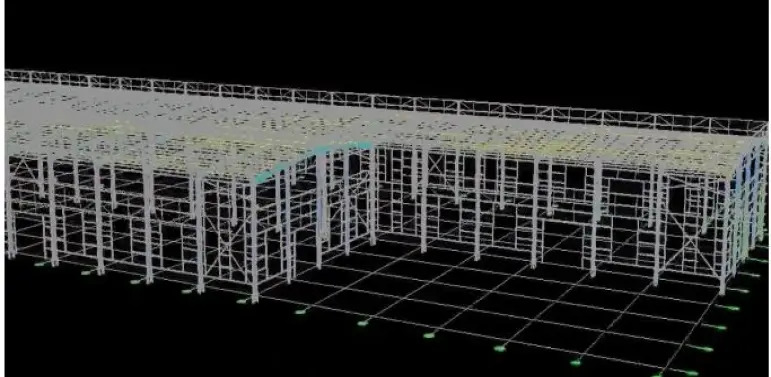

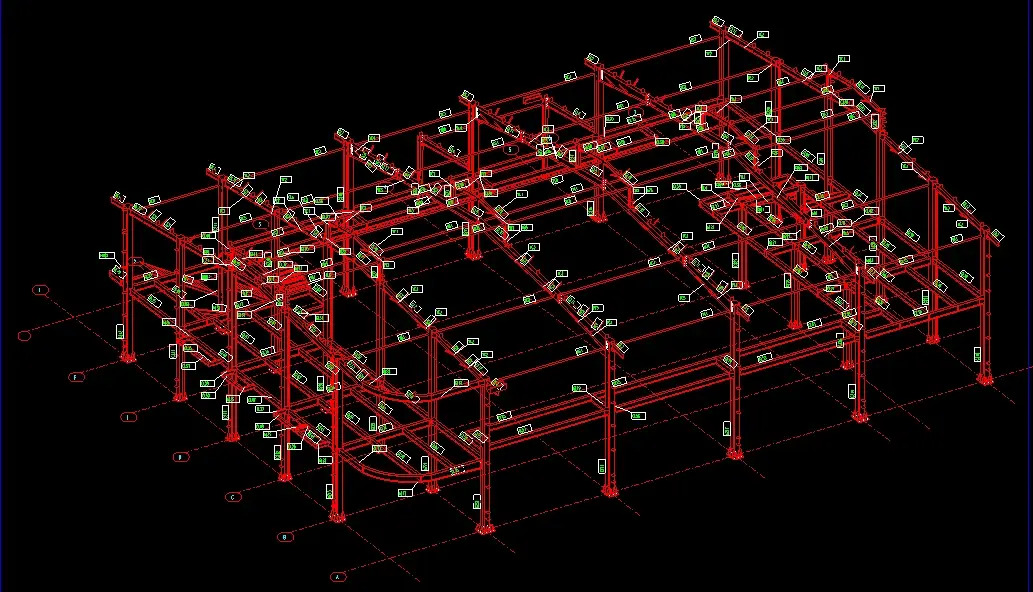

Design 3D max,CAD for steel structure frame

Material Q235,Q345B,SS400 steel structure

Foof Galvanized color sheet or sandwich panel

Wall Galvanized sheet for steel structure workshop

Place of project Indonesia steel structure workshop and warehouse

Delivery time 30 days after steel structure drawing confirmation

Package Steel structure frame pallet for 40HQ container

Application workshop,warehouse,office,commercial bulding,shop

Packging & Delivery

Min Order500 square meter

Briefing

Detailed

ZhengYuanming Construction Engineering Co., Ltd. now is one the prestigious company specializing in Steel Structure | sandwich panel steel structur warehous workshop,workshop light steel structure,warehouse building,light metal structure workshop,high quality steel structure workshop and warehouse,prefabricated modern design steel structure workshop.All of our products comply with international quality standards and clients come from a variety of different markets throughout the world.such as Kazakhstan etc

| Product name |

steel structure building design |

|---|---|

| Brand Name |

ZYM |

| Material |

and stainless steel,Thin-walled steel box beam etc |

| Brand |

ZYM steel structure building design Manufacturer |

| Keyword |

steel structure of the building,Industrial Steel Structure Warehouse,steel structure brick workshop |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| OEM&ODM |

YES |

| Application |

light steel structure warehouse for sale,high quality steel structure warehouse,prefab light big steel structure warehouse |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Cape Verde,Northern Mariana Islands,Monaco,Guyana,Namibia,Micronesia, Federated States of,Swaziland |

ZYM One-Stop Steel Structure Material

ZYM After-Sale Service , we will still provide the service after the steel structure building design installation.

ZYM provide the integrated solutions for our clients . After the steel structure design , we arrange the steel sandwich panel steel structur warehous workshop,workshop light steel structure,warehouse building,light metal structure workshop,high quality steel structure workshop and warehouse,prefabricated modern design steel structure workshop . In the process , we provide the best quality steel structure and the quality is approved steel structure building design services FAQs GuideAre you looking for a quick review guide about steel structure building designservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding steel structure building design services.Let’s continue!

2.Do you offer service for installation?

3.What is the insulation and energy efficiency of steel structure building design?

4.How does the weight of a steel structure building affect site preparation and construction?

5.What are the advantages of prefabricated steel structure building design?

6.What type of maintenance is required for steel structure building design?

7.What is the maximum height that can be achieved with a ?

8.Are steel structure building design resistant to pests and termites?

9.Can steel structure building design be relocated or disassembled?

10.What are the most common applications for steel structure building design?

1.What is the process for constructing a steel structure building?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Design: The first step in constructing a steel structure building is to design the building. This includes determining the size, shape, and layout of the building, as well as the type of steel to be used. 2. Fabrication: Once the design is complete, the steel components must be fabricated. This includes cutting, bending, and welding the steel into the desired shapes and sizes. 3. Erection: Once the steel components are fabricated, they must be erected on the building site. This includes assembling the steel components and connecting them to the foundation. 4. Finishing: The final step in constructing a steel structure building is to finish the building. This includes adding insulation, drywall, and other finishing touches.

2.Do you offer service for installation?

We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if neede.

3.What is the insulation and energy efficiency of steel structure building design?

We actively participate in the steel structure building design industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion Steel structure buildings are highly energy efficient and can be insulated to meet the highest energy efficiency standards. Steel is a great conductor of heat, so it is important to use insulation to reduce heat transfer. Steel structure buildings can be insulated with a variety of materials, including fiberglass, cellulose, and spray foam. Steel structure buildings can also be designed to meet the highest energy efficiency standards, such as LEED certification.

4.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of steel structure building design products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

5.What are the advantages of prefabricated steel structure building design?

We continue to invest in research and development and continue to launch innovative products. 1. Cost-Effective: Prefabricated steel structures are cost-effective and can be built quickly, saving time and money. 2. Durability: Steel is a strong and durable material that can withstand harsh weather conditions and is resistant to fire, termites, and other pests. 3. Flexibility: Prefabricated steel structures can be easily modified and adapted to fit any design or purpose. 4. Eco-Friendly: Steel is a recyclable material, making it an environmentally friendly choice for construction. 5. Low Maintenance: Steel structures require minimal maintenance and are easy to clean and repair. 6. Versatility: Prefabricated steel structures can be used for a variety of applications, from residential to commercial and industrial.

6.What type of maintenance is required for steel structure building design?

We enjoy high authority and influence in the industry and continue to innovate products and service models. Steel structure buildings require regular maintenance to ensure they remain structurally sound and safe. This includes inspecting the building for signs of corrosion, checking for loose or damaged fasteners, inspecting the roof and walls for signs of wear, and inspecting the foundation for signs of settlement or cracking. Additionally, it is important to regularly inspect the building for signs of pests or other infestations, and to check for any signs of water damage.

7.What is the maximum height that can be achieved with a ?

We focus on providing high steel structure building design quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

8.Are steel structure building design resistant to pests and termites?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, steel structure buildings are resistant to pests and termites. Steel is a non-porous material, which means that pests and termites cannot penetrate it. Steel is also highly durable and can withstand extreme weather conditions, making it an ideal material for buildings.

9.Can steel structure building design be relocated or disassembled?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services. Yes, steel structure buildings can be relocated or disassembled. Steel structures are designed to be easily dismantled and reassembled, making them ideal for relocation. Steel structures can be disassembled and reassembled quickly and easily, making them a great option for businesses that need to move or expand.

10.What are the most common applications for steel structure building design?

We have a good reputation and image in the industry. The quality and price advantage of steel structure building design products is an important factor in our hard overseas market. 1. Warehouses 2. Industrial Buildings 3. Agricultural Buildings 4. Retail Stores 5. Offices 6. Aircraft Hangars 7. Churches 8. Garages 9. Sports Facilities 10. Carports

You need a product

Related Searches

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Guangdong

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union