Zheflon® PVDF FL2012—Extrusion grade

group namePVDF Extrusion Grade

-

Min Order1 kilogram

brand nameZheflon PVDF & Flurine FKM Manufacturer

modelFL2012

payment methodT/T, L/C

-

update timeFri, 08 Nov 2024 03:28:55 GMT

Paramtents

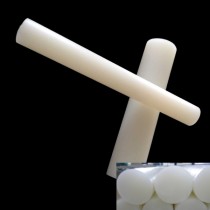

Appearance White and semi-transparent pellets

Features Homopolymer, low viscosity

Application Pipes and fittings, bars

Packging & Delivery

Min Order1 kilogram

Briefing

Detailed

Homopolymer, white granular resin, medium and low viscosity with high purity, good fluidity, good mechanical strength and toughness, suitable for extrusion process.

Physical properties | Unit | Typical Value | Test Method |

|---|---|---|---|

Appearance | —— | White and semi-transparent pellets | —— |

Density | g/cm3 | 1.75~1.77 | ASTM D792,23℃ |

Melt flow rate | g/10min | 1~10 | ASTM D1238, 230℃@5kg |

Intrinsic Viscosity | dl/g | 1.0~1.2 | 30℃,DMAC |

Molecular weight | —— | 280000~360000 | GPC,DMF,ISO 16014 |

Water absorption | % | ≤0.05 | ASTM D570 |

Molding shrinkage | —— | 0.0200~0.0400 | —— |

Mechanical properties | |||

Tensile yield strength | Mpa | ≥45 | ASTM D638 50mm/min@23℃ |

Yield elongation | % | ≥5 | |

Break Strength | Mpa | ≥25 | |

Elongation at break | % | ≥20 | |

Hardness | Shore D | 70~80 | ASTM D2240 |

Thermal properties | |||

Melting point | ℃ | 165~170 | ASTM D3418 |

Crystallizing heat | ℃ | 134~144 | ASTM D3418 |

You need a product

You May Like

- Nearest port for product export

- Ningbo, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C