Hammer mill pulverizer manufacturers in india

- US $12000.00

1 - 10 set

- US $10000.00

11 - 25 set

- US $8000.00

26 - 50 set

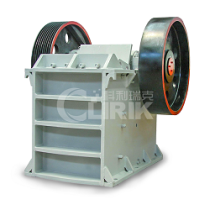

group namecrusher

-

Min Order1 set

brand nameClirik

modelPCC

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal, Cash

-

update timeMon, 16 Dec 2019 14:45:22 GMT

Paramtents

Color as request

Warranty 1 year

Motor Brand Siemens

Motor Type AC

Control System PLC

Feeding Size 25-300 mm

Output Size 0-25 mm

Application coarse powder crushing

After Sales Service engineer online or abroad service

Sales Range worldwide

Packging & Delivery

Size500cm x 400cm x 500cm

Weight800.00kg / set

Min Order1 set

Briefing

Detailed

Application of Hammer mill pulverizer manufacturers in india

Hammer mill pulverizer manufacturers in india is engaging in crushing various rocks and stones(such as Limestone, calcite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, medical stone, rock phosphate, manganese ore, quartz, active carbon,glass and so on) with comprehensive strength not higher than 320 MPa into coarse powder and small particles, it is widely used in metallurgy, mining, chemical, cement, coal, sand-making, c construction, refractory materials and ceramic industries.

Working principle of Hammer mill pulverizer manufacturers in india

Hammer mill pulverizer manufacturers in india mainly consists of frame, rotor, support iron and grate bars. The frame is divides into two parts: upper part and low part, which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out. The rotors consist of turn plates, pin shafts, and hammers which are grouped regularly in the main shaft. The main unit drives the main shaft through the motor and triangle belts, which, in turn, rotates the rollers. Large materials entering the crusher through the feed inlet are firstly crushed by the high-speed hammers, and the thrown fiercely to the support iron for further crushing. Qualified materials crushed will be screened out and exit from the gap of the grate bars while the unqualified will be left in the crushing cavity to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the grate bars. The gap between the rotors and the grate bars can also be adjusted according to different requirement. To avoid the plugging of the crusher, the proportion of water for the crushing material is no more than 20%.

Advantages of Hammer mill pulverizer manufacturers in india

1. Uniform particle size with high crushing ratio;

2. High capacity and decrease power consumption by 20-30%;

3. Simple structure; Easy operation;

4. Low investment and environment friendly.

Technology Data of Hammer mill pulverizer manufacturers in india

Type | PC4008-75 | PC4012-90 | PC4015-132 |

Rotor Diameter /mm | 750 | 900 | 1150 |

Rotor Width/ mm | 800 | 1200 | 1500 |

Rotor Speed/ r/min | 800-1000 | 800-1000 | 550-800 |

Max Feeding Size/mm | <50 | <60 | <80 |

Finished particle size /mm | 0-3 | 0-3 | 0-8 |

Capacity / t/h |

10-30 |

30-60 | 50-100 |

Power /kw | 55-75 | 75-90 | 45 |

Hammer Number /pieces | 18 | 32 | 32 |

Dimension L*W*H/mm | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow