High Capacity and Flexible Rail-Mounted Telescopic Ship Loader for Bukl Material Handling

group nameShip Loading Belt Conveyor

-

Min Order1 piece

brand nameSKE

payment methodL/C, Western Union, T/T

-

update timeFri, 19 Jul 2024 22:12:27 GMT

Paramtents

color customized

Packging & Delivery

Min Order1 piece

Briefing

Detailed

High Capacity and Flexible Rail-Mounted Telescopic Ship Loader for Bukl Material Handling

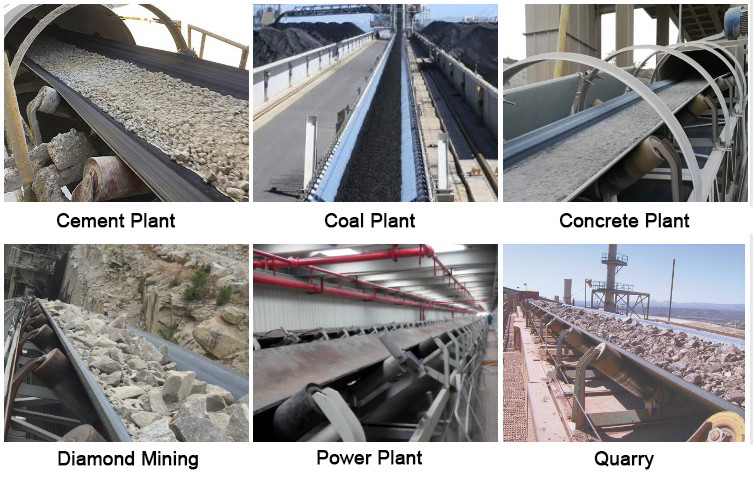

Application:

Advantages:

Tech Datasheet

| Rail mounted Radial Telescopic Ship Loader Conveyor System | |

|---|---|

| Barge Loading Capacity (t/h) | 3000 tons per hour |

| Full Conveyor Length (m) | 58 (Full extended Length in Working) |

| Driving Power | Fully integrated generators to power entire ship loading system. |

| Environment Protection | Dust Suppression Measures – Galvanised / Canvas Dust covers, Telescopic dust covers, dust extraction, Integrated telescopic chutes (Free-fall – Cascade Design), 360 degree trimmer chutes, Rubber ‘sock’ chutes, water suppression and many more. |

| Traveling Method | Parallel travelling |

| Electrical Integration | Communication interlinks, radio remote controls, Ethernet connections and many more. |

| Belt Upgrade | Heavy duty conveyor belt, Chevron belt, etc. |

You need a product

You May Like

- Nearest port for product export

- Shanghai,China

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union