Standard Helical Spur Gear Mod 3 | 32/48 Pitch Gear | Stainless Steel | Aluminum | Metal | Gear Manufacturer |Customized Service

- US $0.50

1 - 10,000 piece

group nameMetric Spur Gear

-

Min Order1 piece

brand nameCTS-ChinaTransmissionS

payment methodL/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal

-

update timeThu, 07 Nov 2024 23:53:43 GMT

Paramtents

product name spur gear

colour natural

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

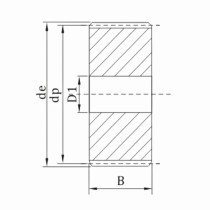

Mod No.

|

External diameter(de)

|

Pitch

Diameter (dp) |

Number of Teeth

|

Width between inner plates(D1) | Hub diameter (dm) | Tooth width "A" (mm) | Tooth width "B" (mm) |

Mod.1 | 14-129 | 12-127 | 12-127 | 8-12 | 9-50 | 25 | 15 |

Mod.1.5 | 21-193.5 | 18-190.5 | 12-127 | 8-16 | 14-70 | 30 | 17 |

Mod.2 | 28-258 | 24-254 | 12-127 | 10-20 | 18-80 | 35 | 20 |

Mod.2.5 | 35-155 | 30-150 | 12-127 | 10-20 | 22-100 | 45 | 25 |

Mod.3 | 42-387 | 36-381 | 12-127 | 12-30 | 27-100 | 50 | 40 |

Mod.4 | 56-464 | 48-456 | 12-127 | 14-30 | 35-80 | 60 | 40 |

Mod.5 | 70-580 | 0-570 | 12-127 | 20-30 | 45-110 | 75 | 50 |

Mod.6 | 84-252 | 2-240 | 12-127 | 20-25 | 54-110 | 80 | 60 |

Spur gears

Spur gears are the simplest type of gear,which consist of a cylinder or disk with teeth projecting radially and used in industrial equipment to transfer mechanical motion as well as control speed,power,and torque.Spur gears can be made of many materials, such as metal, aluminum, stainless steel, etc., and have helical tooth and straight tooth,all depending on your needs.

Our company can supply precision gears. According to the needs of different working conditions, it can be used for normalizing, quenching and tempering, carburizing and quenching. The company has high-precision grinders, CNC forming grinders, surface grinders, cylindrical grinders, gear hobbing machines and other finishing equipment, which can grind straight gears, helical gears, spiral bevel gears, gear shafts and other gear products. At the same time, various non-standard special transmission machinery products can be produced according to user requirements. The quality of materials used is good, and the processing precision is high.

We provide 7*24 online service, and there is a dedicated person in charge to provide one-to-one service, and it can be shipped within 48 hours at the fastest. The products will be strictly inspected before leaving the factory, and passed the product quality certification, only to provide you with satisfactory products.

Application industries

√Manufacturing

√Agriculture

√Building Material

√Oil and Gas

√Technology and Science

Package

Plastic bag+Neutral box +Plywood box

Pressure angle:20°

Quality Assurance

ISO9001: 2015 and GB/T24001-2016 / ISO14001: 2015.

You need a product

You May Like

- Nearest port for product export

- Shanghai, Ningbo, Tianjing, Guangzhou

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash