DG-PM Asphalt Mixing Plant

group nameBatch Type Asphalt Mixing Plant

-

Min Order1 piece

brand nameD&G Asphalt Plant Manufacturer

modelDG1300PM-DG2000PM

payment methodL/C, T/T

-

update timeFri, 08 Nov 2024 07:37:14 GMT

Paramtents

Rated capacity 80t/h-160t/h

Dust collector Primary gravity+ Bag filter

Place of origin China

Total Power 192-262 KW

Transport and Installation 10-15 pcs 40HC and quick erection

Packging & Delivery

Min Order1 piece

Briefing

Detailed

- If you are planning to establish an asphalt mixing plant and would like to know about cost budgeting and how to select and price asphalt mixing plants, we will provide you with more technical support regarding the early stages of your asphalt mixing plant. Additionally, if you wish to become a distributor of D&G's localized asphalt mixing plant, we will offer you more support to expand your local market. Contact us now for more information about D&G Machinery asphalt mixing plant consultations.

DG-PM asphalt mixing plant has complete product lineup including stationary, mobile asphalt batch mix plant and continuous drum mix plant. Thanks to the compact design it can be proper for some tight space with fully functions. Accurate control system, fast responding active and stable quality can satisfy almost all customer's need in more economical way. It designed and manufactured in accordance with Europe quality standard with CE&EAC certification. The plants adopted the top-class components to ensure the running stability and long service life.

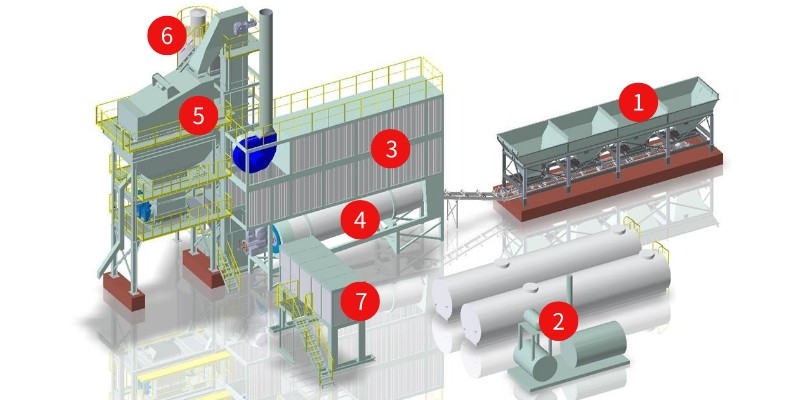

1. Cold feeder system

2. Bitumen storage & heating system

3. Dust collecting system

4. Drying system

5. Mixing tower system

6. Filler system

7. Control Room

1) Foldable coaming to be loaded into 40‘HC. Quick removable structure of the belt conveyor. Easy maintenance. D&G owned Patent.

2) Extract endless belt with skirt to prevent aggregate from spilling.

1) The drum with chassis (base plate) can be loaded into a 40'HC.

2) High transmission efficiency with 4 units direct-connection powertrain system.

3)Drying drum with thermal insulation to avoid energy loss.

1) Foldable handrails & platforms and stairs are integrated with mixing tower.

2) Elevator are fixed with mixing tower by positioning bolt. Easy to be relocated.

3)Each module can be packed in a 40'HC standard container and trailer. Quick installation and delivery.

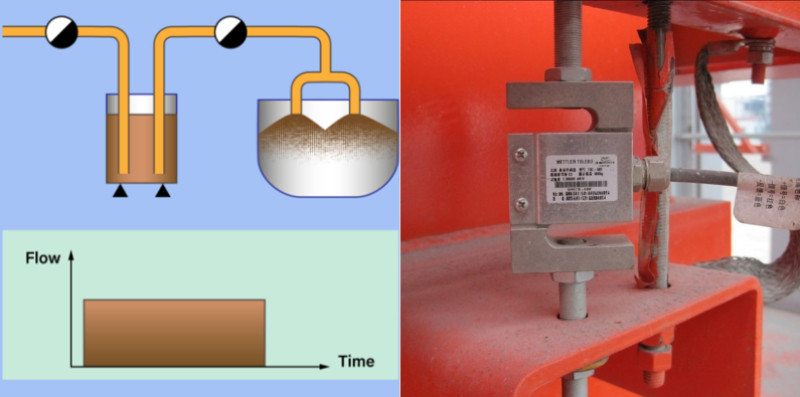

1) Weighing system adopt 3-points weighing sensor (load cell), signal is directly transmitted to control computer; weighing system has auto compensation function.

2) Secondary intelligent bitumen measurement.

1) Mixing arms, paddles and liners are made of wear resistant material.

2) Synchronized twin shafts driven by Rossi gearbox.

1) Dust collector is placed upon the dryer drum to save space.

2 NOMEX filter bags.

3) Two stages dust collecting system: primary gravity+ bag filter.

4) All handrails can be folded up.

1) ABS burner imported from Italy.

2) Automatic, low noise, less emission, low energy consumption and cost saving.

3) Various fuel available: diesel, coal, heavy oil or natural gas.

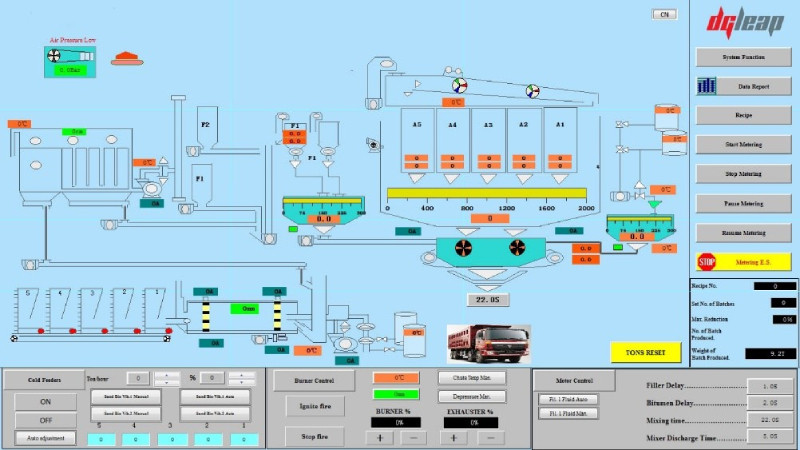

1) "DG LEAP" Automatic and manual control can be switched.

2) System configured with Siemens PLC.

1) Double vibrating motors.

2) Special designed wear-proof clapboard.

MODEL-Modular Series | DG1300PM | DG1500PM | DG2000PM |

Rated Production Capacity | 105t/h | 125t/h | 160t/h |

Cold Feeder Bin | 6.5m³ x 4 | 8m³ x 4 or 5 | 8m³ x 5 or 6 |

Dry Drum Size | Ø 1.8m x 7.5 m | Ø 1.9m x 7.5m | Ø 2.0m x 8.5m |

Dust Collector | Primary gravity+ Bag filter | ||

|

Screen

|

4

|

4 or 5 |

5 or 6

|

Screening Area | 14.88 ㎡ | 13 ㎡ | 20 ㎡ |

Hot Bin Volume | 18.2 m³ | 14 m³ | 20 m³ |

Mixer Capacity | 1300kg | 1550kg | 2000kg |

Control System | DG Leap + PLC | ||

Emission Rank | ● Dust Density ≤ 20 mg/Nm³ | ||

● Cabin Noise ≤ 70 dB | |||

|

● Ringelmann Blackness Class Ⅰ

|

|||

|

Note:

|

|||

|

●Some specifications / options might not be available in some countries due to local regulations.

|

|||

● Specifications / options are constantly updated and subject to change. | |||

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A, Cash