DGX Asphalt Mixing Plant

group nameRAP Batch Asphalt Mixing Plant

-

Min Order1 piece

brand nameD&G Asphalt Plant Manufacturer

modelDGX2000-DGX5000

payment methodL/C, T/T

-

update timeFri, 08 Nov 2024 17:38:22 GMT

Paramtents

Mixer Capacity 2000-6000kg

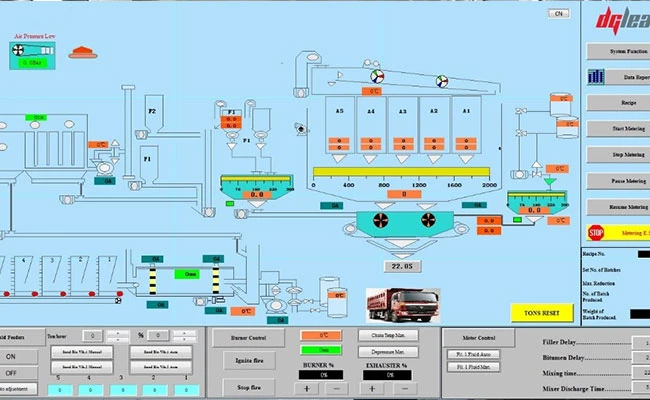

Control System DG Leap + PLC

Dust Collector Primary gravity + Bag filter

Place of Origin China

Feature Best performance, High Productivity

Packging & Delivery

Min Order1 piece

Briefing

Detailed

- If you are planning to establish an asphalt mixing plant and would like to know about cost budgeting and how to select and price asphalt mixing plants, we will provide you with more technical support regarding the early stages of your asphalt mixing plant. Additionally, if you wish to become a distributor of DG's localized asphalt mixing plant, we will offer you more support to expand your local market. Contact us now for more information about DG asphalt mixing plant consultations.

DGX asphalt mixing plant adopts the idea of cross model on planning and design, which can realize the conversion of different equipment styles and functions and meet the requirements of different production conditions with each functional module is combined according to different modes. For the need of production, which can be assembled according to its type.

SPECIFICATION | |||||

MODEL-DGX Series | DGX2000 | DGX3000 | DGX4000 | DGX4500 | DGX5000 |

Rated Production Capacity | 180 t/h | 240 t/h | 320 t/h | 360 t/h | 400 t/h |

Cold Feeder Bin | 5 x 10m3 | 5 x 18m3 | 6 x 18m3 | 6 x 18m3 | 6 x 18m3 |

Dryer Drum Size | Ø 2.2m x 9m | Ø 2.5m x 9m | Ø 2.8m x 12m | Ø 2.8m x 12m | Ø 3.0m x 12m |

Dust Collector | Primary gravity + Bag filter | ||||

|

Screen

|

5 |

5 or 6

|

6 |

6

|

6 |

Hot Bin Volume | 21m³ | 45m³ | 75m³ | 75m³ | 80m³ |

Mixer Capacity | 2000kg | 3300kg | 4200kg | 5500kg | 5500kg |

Control System | DG Leap + PLC | ||||

Emission Rank | ● Dust Density ≤ 20 mg/Nm³ | ||||

● Cabin Noise ≤ 70 dB | |||||

● Ringelmann Blackness Class Ⅰ |

|||||

|

Note:

|

|||||

|

● Some specifications / options might not be available in some countries due to local regulations.

|

|||||

● Specifications / options are constantly updated and subject to change. | |||||

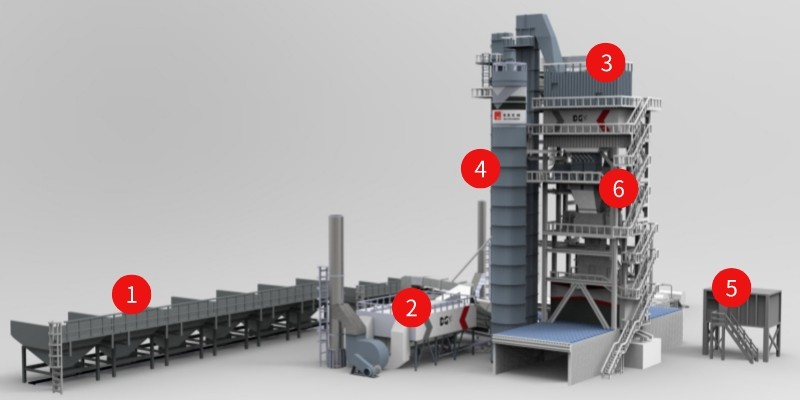

1. Cold feeder system

2. Dust collecting system

3. Vibrating screen

4. Filler system

5. Control room

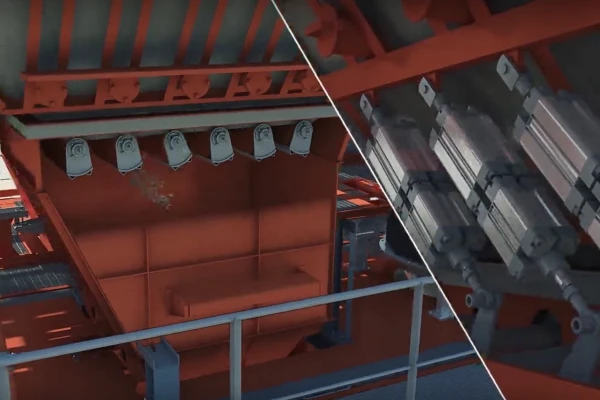

6. Mixing tower

1) Frequency inverter belt conveyor.

2) Each compartment is equipped with an aggregate shortage alarming device.

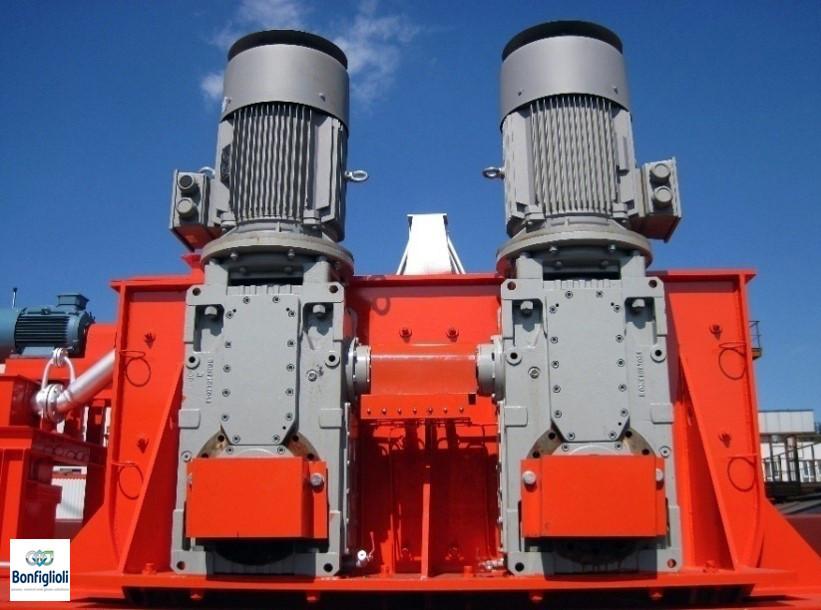

3) Belt driving system consisted of Siemens motor+ Bonfiglioli reducer+ SKF bearing.

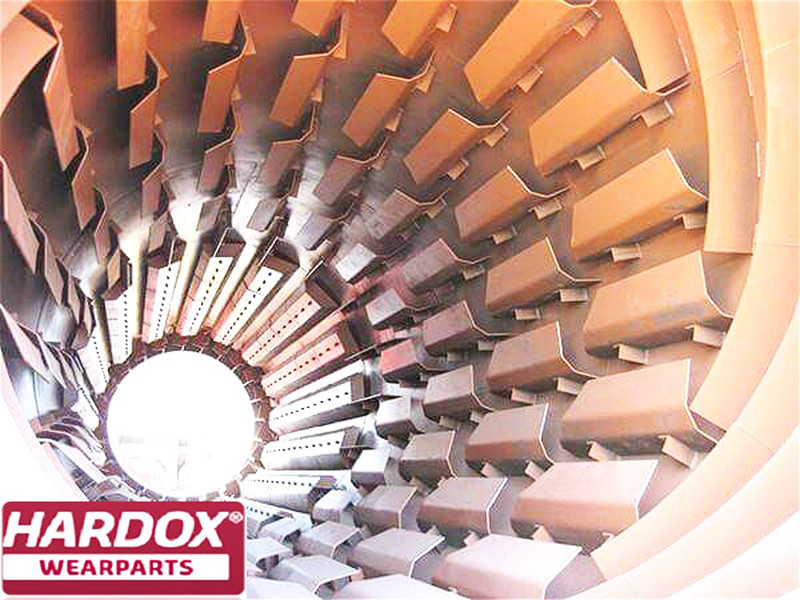

1) The drum flights are applied in HARDOX high strength wear-resistance steel to prove long service time.

2) Employing thermal insulating rock wool material that can keep the energy inside, reducing heat loss.

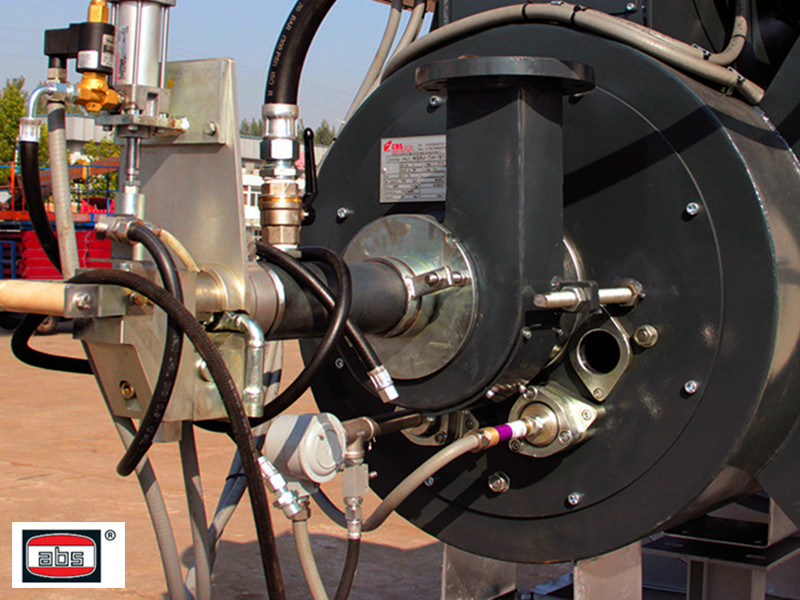

3) Multiple-function ABS burner, kinds fuel (gas, oil, diesel, coal) can be chosen as required.

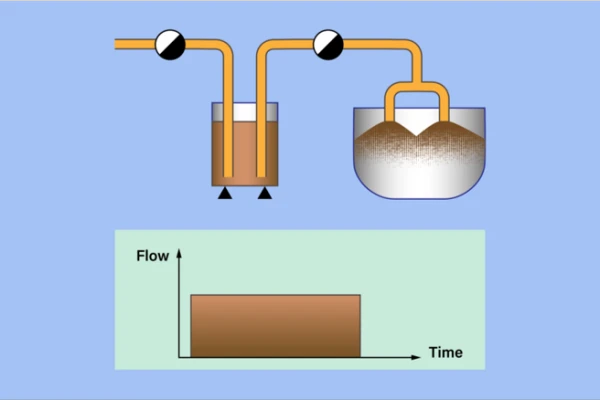

1) Two stage dust filtration system: primary gravity+ bag filter.

2) Frequency control exhaust fan.

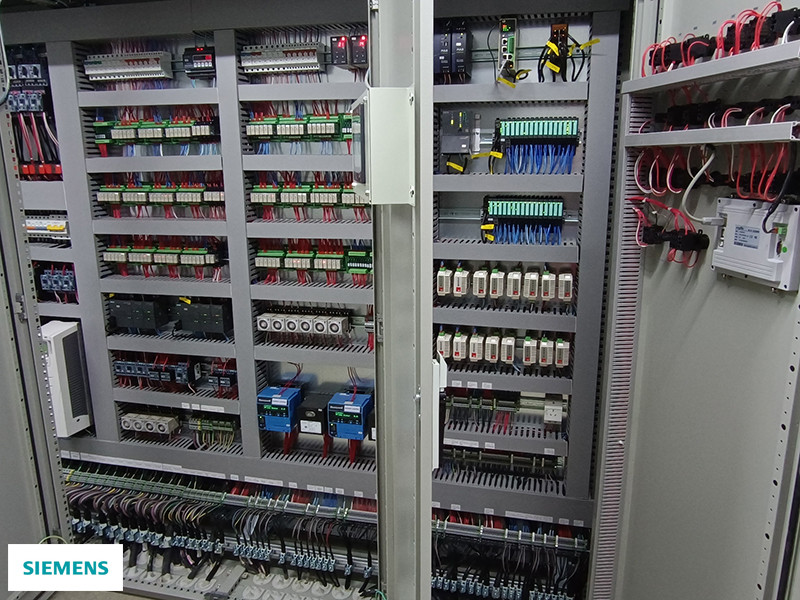

1) "DG LEAP" Automatic and manual control can be switched.

2) System configured with Siemens PLC.

1) Thick thermal insulation layer on bitumen tanks and pipes, minimal heat loss.

2) Liquid level indicators and thermometers are installed on bitumen tanks; easy for observation and operation.

3) Circulating pump to control the bitumen flow.

1) Double vibration motor.

2) Sufficient vibrating force to prove high sieving efficiency.

You need a product

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A, Cash