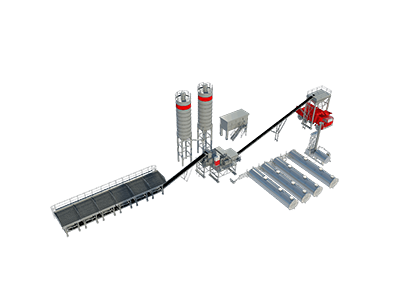

Cold Recycling Plant Mixing Equipment

group nameCold Recycling Plant Mixing Equipment

-

Min Order1 piece

brand nameD&G Asphalt Plant Manufacturer

modelMultiple Models

payment methodL/C, T/T

-

update timeFri, 08 Nov 2024 09:51:04 GMT

Paramtents

Capacity (t/h) 500-800

Origin of Place China

Color Customizable

Packging & Delivery

Min Order1 piece

Briefing

Detailed

|

Model

|

CRP500

|

CRP600

|

CRP800 |

|

Theoretical Production Rate (t/h)

|

500

|

600

|

800 |

Mixing Machine | Double Horizontal Shaft Forced Mixer | Double Horizontal Shaft Forced Mixer | Double Horizontal Shaft Forced Mixer |

Single Mixing Machine Power (kw) | 75 | 2x55 | 2x55 |

Number of Mixers | 2 | 2 | 2 |

Maximum Aggregate Particle Size (mm) | 60 | 60 | 60 |

Aggregate Measurement Accuracy | ±2% | ±2% | ±2% |

Filler Measurement Accuracy | ±1% | ±1% | ±1% |

Water Measurement Accuracy | ±1.5% | ±1.5% | ±1.5% |

Bitumen Measurement Accuracy | ±1.5% | ±1.5% | ±1.5% |

Bitumen Scale Capacity | 400L | 450L | 500L |

Aggregate Bin Volume | 4×10m³ | 5×13m³ | 5×15m³ |

Filler Silo Capacity | 2×100T | 2×100T | 2×100T |

Hot Mix Storage Bin Volume | 7m³ | 7m³ | 10m³ |

Discharge Height | 3.7m | 3.7m | 4m |

Bitumen Tank Volume | 2×50m³(optional) | 2×50m³(optional) | 2×50m³(optional) |

Emulsified Asphalt Tank Volume | 2×50m³(optional) | 2×50m³(optional) | 2×50m³(optional) |

Installed Power (Incl. Optional Equipment) | 366kW | 451kW | 474kW |

Overall Dimensions (Length × Width × Height) | 48m×34m×20.5m | 56m×34m×21m | 67m×34m×21.5m |

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A, Cash