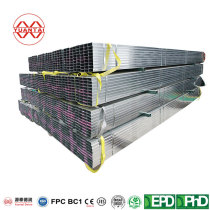

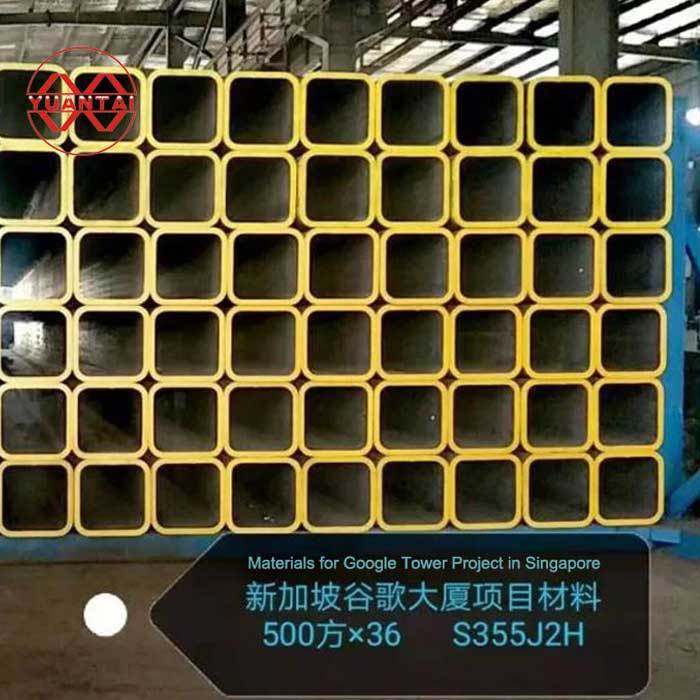

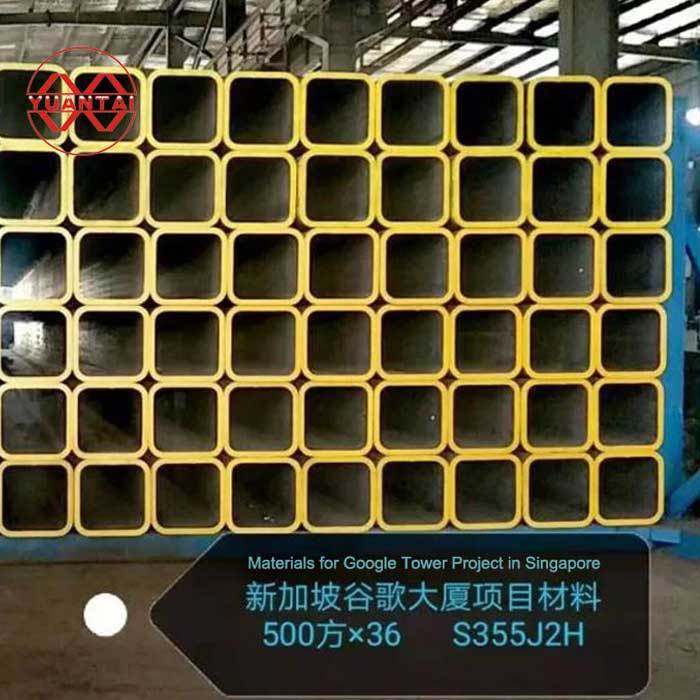

EN10219 Cold Formed Black Carbon Steel Welded Square Tube

group namesquare steel pipe

-

Min Order5 ton

brand nameYuantai Derun Steel Pipe Manufacturing Group

modelen10219 hollow section

payment methodL/C, T/T

-

update timeFri, 01 Nov 2024 09:26:56 GMT

Paramtents

Thickness 0.5- 60 mm

OD(Outer diameter) 10*10-1200*1200mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

Surface Treatment Black painted or REQUEST

Tolerance as required

Length 0.5-26.5M according to client requirement

Delivery Time 7-30 Days

Packging & Delivery

Min Order5 ton

Briefing

Detailed

EN10219 Cold Formed Black Carbon Steel Welded Square Tube

Complete EN10219 Cold Formed Black Carbon Steel Welded Square Tube Sizes For You

O.D.(mm) | THK(mm) | O.D.(mm) | THK(mm) | O.D.(mm) | THK(mm) | O.D.(mm) | THK(mm) |

20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

2.0 | 2.5-4.0 | 11.5-11.75 | | ||||

20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | | |||

1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | | ||

1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

2.2 | 2.20 | 13.5-13.75 | | ||||

2.5-3.0 | 2.5-2.75 | 15.5-30 | | ||||

20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | | |

1.4 | 5.5-6.3 | 4.5-4.75 | | ||||

1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

2.2 | 2.75 | 13.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | | ||

3.25-4.0 | 5.5-6.3 | 4.5-4.75 | | ||||

25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

1.8 | 3.0-3.75 | 12-13.75 | | ||||

2.0 | 4.5-4.75 | 15.5-30 | | ||||

2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | | ||

2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

5.75-6.3 | 3.0-4.75 | 15.5-30 | | ||||

40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 800*800 | | |

1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

2.2 | 2.75 | 15.5-30 | | ||||

2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | | ||

3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | | |||

1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | | ||

1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | | |||

3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | | ||

4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

1.5 | 12.25 | 15.5-40 | | ||||

1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 450*450 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | | |

1.8 | 4.5-6.3 | 9.5-9.75 | | ||||

2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

2.2 | 9.5-9.75 | 12-13.75 | | ||||

2.5-3.0 | 11.5-25 | 15.5-40 | | ||||

3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | | |

4.25-4.75 | | 3.5-3.75 | 11.5-11.75 | 20-60 | |||

5.0-5.75 | | 4.25-7.75 | 12-13.75 | | |||

7.5-8 | | 9.5-25 | 15.5-40 |

Types Of EN10219 Cold Formed Black Carbon Steel Welded Square Tube

Coating Of EN10219 Cold Formed Black Carbon Steel Welded Square Tube

Advantage Of EN10219 Cold Formed Black Carbon Steel Welded Square Tube

The weld seam is tight and sturdy

The surface of the pipe body is smooth and straight, with good straightness

Uniform thickness

The pipe end is flat and free of burrs

The inner wall of the pipe shall be flat and smooth without burrs

Safe transportation in its own fleet

Free EN10219 Cold Formed Black Carbon Steel Welded Square Tube Samples For You

Chemical Composition

Structural hollow sections of non-alloy quality steels - Chemicalcomposition and mechanical properties | ||||||

|

Steel Grade

|

% by mass, maximum |

|||||

C | Si | Mn | P | S | Nb | |

|

S235JRH

|

0.17 | - | 1.40 |

0.040

|

0.040

|

0.009

|

S275J0H | 0.20 | - | 1.50 | 0.035 | 0.035 | 0.009 |

S275J2H | 0.20 | - | 1.50 | 0.030 | 0.030 | - |

S355J0H | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

|

S355J2H

|

0.22 | 0.55 | 1.60 |

0.030

|

0.030

|

-

|

|

S355K2H

|

0.22 | 0.55 | 1.60 |

0.030

|

0.030

|

-

|

Mechanical Properties

Mechanical properties of non-alloy steel hollow sections in thicknesses ≤ 40 mm | ||||||||

|

Steel Grade

|

Minimum yield strength(MPa) | Tensile strength(MPa) | Minimum impact

energy | Minimum elongation |

||||

Specified thickness (mm) | Specified thickness

(mm) | at test temperature of | Specified thickness(mm) | |||||

≤16 | >16≤40 | <3 | ≥3≤40 | -20°C | 0°C | 20°C | ≤40 | |

|

S235JRH

|

235 | 225 | 360-510 |

360-510

|

-

|

-

|

27 | 24 |

S275J0H | 275 | 265 | 430-580 | 410-560 | - | 27 | - | 20 |

S275J2H | 275 | 265 | 430-580 | 410-560 | 27 | - | - | 20 |

S355J0H | 355 | 345 | 510-680 | 470-630 | - | 27 | - | 20 |

|

S355J2H

|

355 | 345 | 510-680 |

470-630

|

27

|

-

|

- | 20 |

|

S355K2H

|

355 | 345 | 510-680 |

470-630

|

40

|

-

|

- | 20 |

Value-Added Services

Capacity And Inventory

Strict Testing

Authoritative Certification

Packaging And Logistics

Application

FAQS

You need a product

You May Like

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash