Galvanized Square Steel Pipe| China factory |EN10219 S420MH |rectangular steel pipe wholesaler

group namegalvanized steel pipe

-

Min Order30 ton

brand nameYuantai Derun Steel Pipe Manufacturing Group

modelhfw-yt-044

payment methodL/C, T/T

-

update timeTue, 05 Nov 2024 02:32:18 GMT

Paramtents

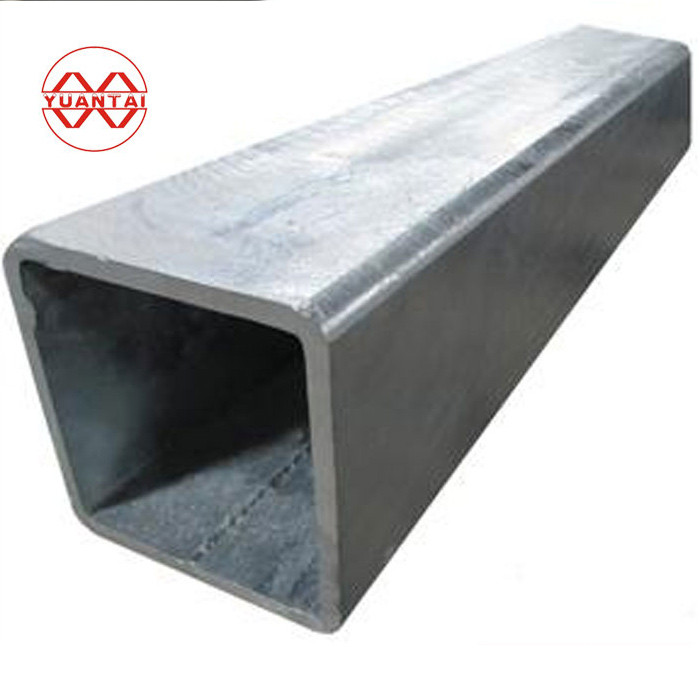

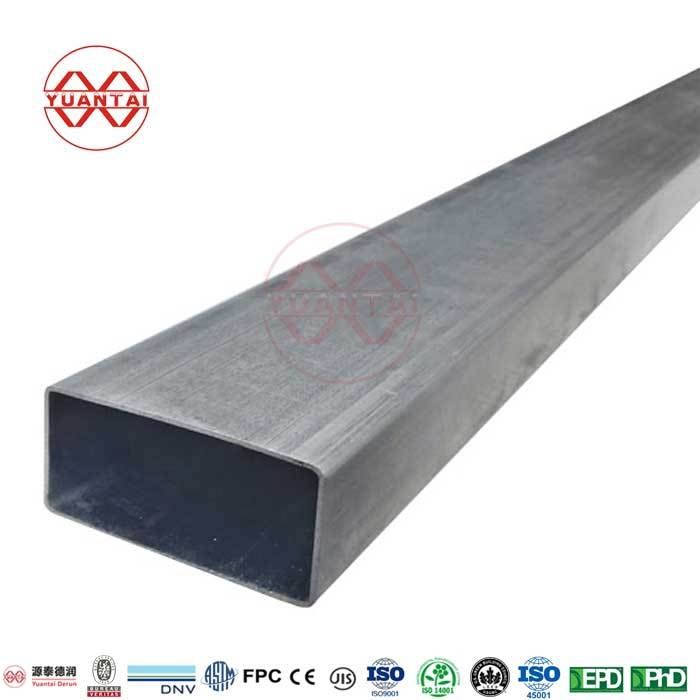

Thickness 0.5- 60 mm

OD(Outer diameter) 10*10-1000*1000mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

Surface Treatment galvanized

Tolerance as required

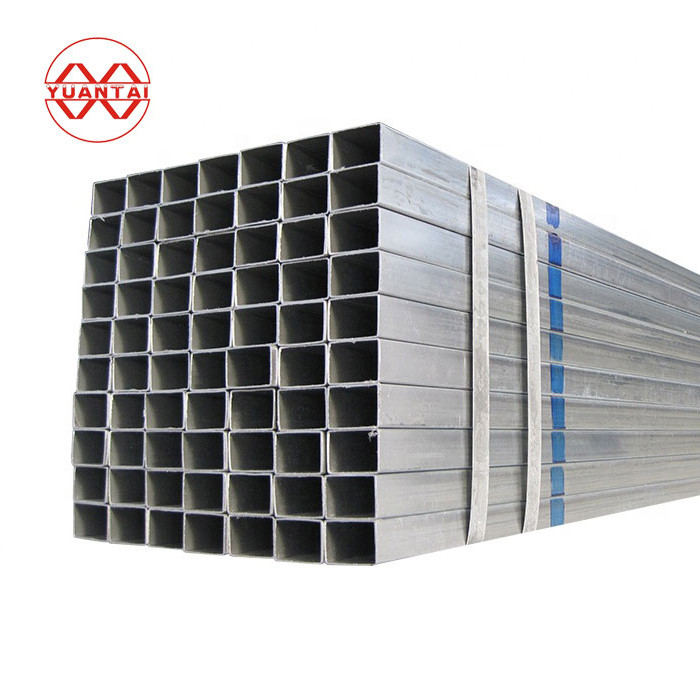

Length 0.5-24M according to client requirement

Materials S420MH

Delivery Time 7-30 Days

Packging & Delivery

Min Order30 ton

Briefing

Detailed

Galvanized Square Steel Pipe| China factory |EN10219 S420MH |rectangular steel pipe wholesaler

I. Galvanized Square Rectangular Steel Pipe Basic Infomation

EN10219 S420MH Galvanized Square Steel Pipe Chemical Composition

EN10219 S420MH Galvanized Rectangular Steel Pipe Mechanical Properties

Yuantai Derun Steel Pipe group-Top Galvanized Square Steel Pipe Manufacturer In China

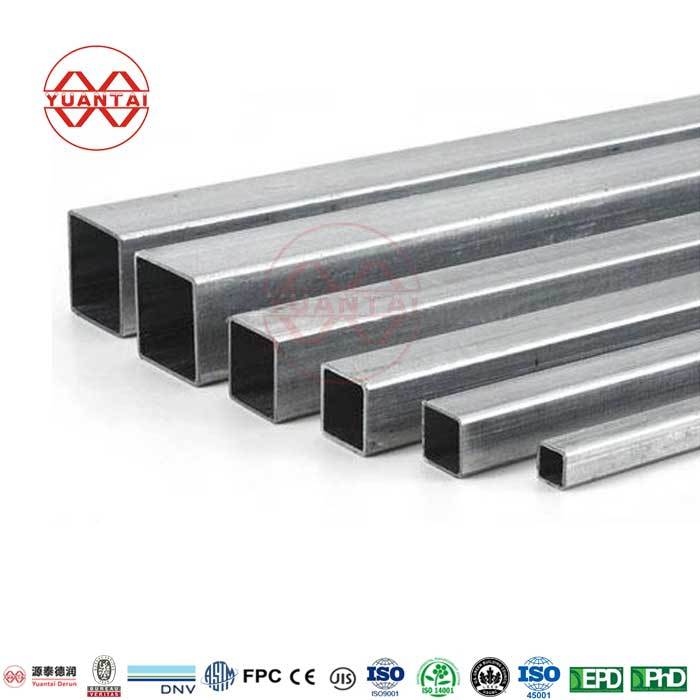

12 factories, 103 production lines, 80 patented technologies, China's top 500 private enterprises and China's top 500 manufacturing industries, with an annual output of 5 million tons and a perennial spot supply of 200000 tons. China's largest square tube manufacturer.

YuantaiDerun's main products include square steel pipe, rectangular steel pipe, hot-dip galvanized steel pipe, ERW steel pipe, large-diameter thick wall square rectangular pipe, LSAW steel pipe, spiral steel pipe, seamless steel pipe, stainless steel pipe, galvanized coil, ppgi coil and Zinc aluminum magnesium steel coil.

III. Qualification & Honor

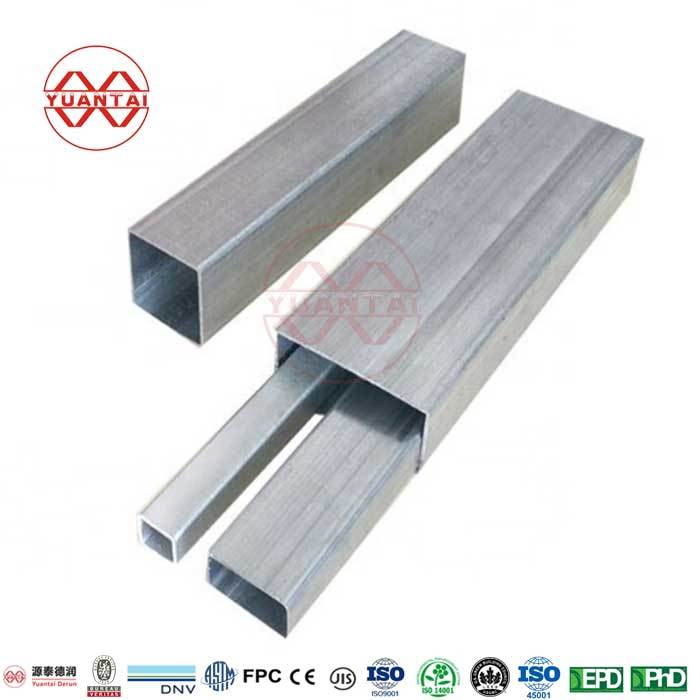

Pipe orifice leveling

Complete specifications

Uniform thickness

High yield

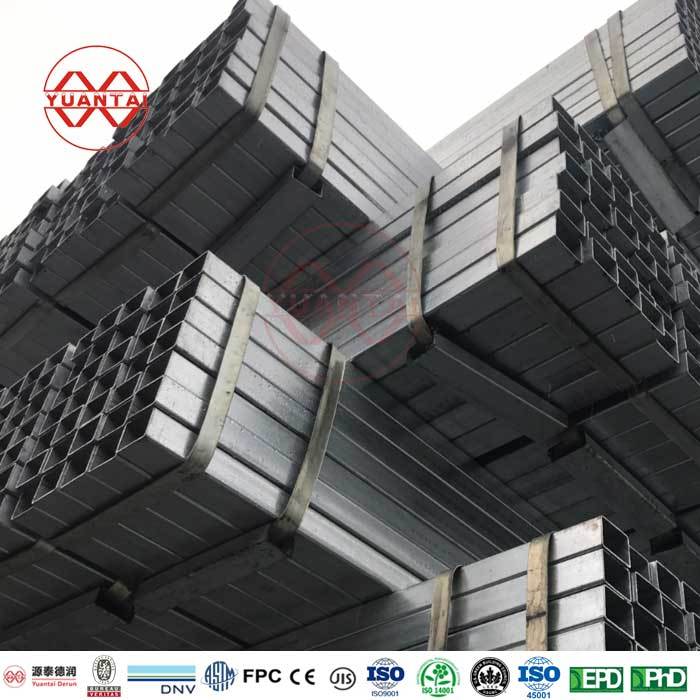

200000 tons of spot supply

The length can be customized

You need a product

You May Like

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash