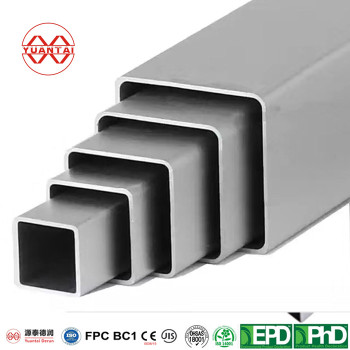

Square Metal Tubes by Yuantai Derun - China's Leading Manufacturer - Customize & Wholesale options available for your business.

Galvanized Square Metal Tubes: Yuantai Derun - China's Premier Manufacturer - OEM, ODM, Wholesale

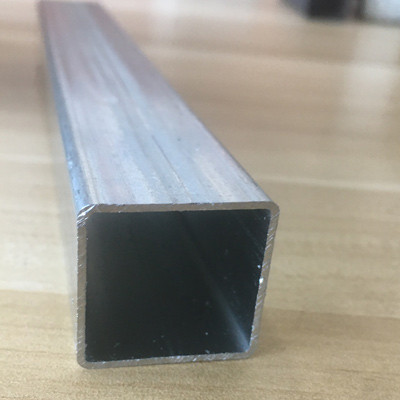

What is a Square Metal Tube?

Square metal tubes are versatile structural components widely used in various industries and applications. They offer unique benefits and are available in different sizes to suit specific needs. In this article, we will explore the features, advantages, sizes, and applications of square metal tubes, focusing particularly on 3x3 and 4x4 square tubes.

Advantages of Using Square Metal Tubes

Square metal tubes offer several advantages over other structural components. Firstly, their square shape provides enhanced stability and load-bearing capacity compared to round tubes. Additionally, square metal tubes are easy to work with, allowing for seamless connections and welding. They are also resistant to corrosion and can withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

Common Materials Used for Square Metal Tubes

Square metal tubes are available in different materials, each offering unique properties. Steel square tubes are the most common choice due to their strength, durability, and cost-effectiveness. Aluminum square tubes, on the other hand, are lightweight and corrosion-resistant, making them suitable for applications where weight is a concern. Other materials, such as stainless steel and brass, are also used for specific applications that require their specific qualities.

Sizes and Dimensions of Square Metal Tubes

Square metal tubes come in a wide range of sizes and dimensions, allowing for customized solutions. Common sizes include 1x1, 2x2, 3x3, and 4x4 square tubes. The size and wall thickness of the tube determine its strength and load-bearing capacity. It is essential to select the appropriate size based on the specific requirements of the project

O.D. mm | W.T.mm | O.D mm | W.T. mm | O.D mm | W.T. mm | O.D mm | W.T. mm |

20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 |

1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 |

1.7 | 2.00 | 5.5-7.75 | 12-13.75 |

1.8 | 2.20 | 9.5-9.75 | 15-50 |

2.0 | 2.5-4.0 | 11.5-11.75 | |

20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | |

1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |

1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 |

1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 |

1.8 | 1.70 | 11.5-11.75 | 12-13.75 |

2.0 | 2.00 | 12.5-12.75 | 15-50 |

2.2 | 2.20 | 13.5-13.75 | |

2.5-3.0 | 2.5-2.75 | 15.5-30 | |

20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | |

1.4 | 5.5-6.3 | 4.5-4.75 | |

1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 |

1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 |

1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 |

2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 |

2.2 | 2.75 | 13.5-30 | |

2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |

3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |

25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 |

1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 |

1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 |

1.7 | 2.75 | 11.5-11.75 | 15-50 |

1.8 | 3.0-3.75 | 12-13.75 | |

2.0 | 4.5-4.75 | 15.5-30 | |

2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |

2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 |

3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 |

4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 |

5.0-5.75 | 2.75 | 12-13.75 | 15-50 |

5.75-6.3 | 3.0-4.75 | 15.5-30 | |

40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 800*800 | |

1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 |

1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 |

1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 |

2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 |

2.2 | 2.75 | 15.5-30 | |

2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |

3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 |

4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 |

5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 |

1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | |

1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |

1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 |

2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

2.2 | 11.5-20 | 12-13.75 | 15-50 |

2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | |

3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |

4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 |

5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 |

1.5 | 12.25 | 15.5-40 | |

1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 450*450 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | |

1.8 | 4.5-6.3 | 9.5-9.75 | |

2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 |

2.2 | 9.5-9.75 | 12-13.75 | |

2.5-3.0 | 11.5-25 | 15.5-40 | |

3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1200*1200 | |

4.25-4.75 | | 3.5-3.75 | 11.5-11.75 | 20-60 |

5.0-5.75 | | 4.25-7.75 | 12-13.75 | |

7.5-8 | | 9.5-25 | 15.5-40 | |

Factors to Consider When Choosing Square Metal Tubes

Several factors should be considered when selecting square metal tubes. These include the material, size, wall thickness, and required load-bearing capacity. It is crucial to assess the specific project requirements and consult with experts to ensure the right choice is made. Factors such as cost, availability, and aesthetics may also influence the decision-making process.

Over view of Yuantai Derun steel pipe group

Universal structural steel pipe service provider

8 factories, 103 production lines, 80 patented technologies, China's top 500 private enterprises and China's top 500 manufacturing industries, with an annual output of 5 million tons and a perennial spot supply of 200000 tons. China's largest square tube manufacturer.

Yuantai Derun's main products include square steel pipe, rectangular steel pipe, Galvanized Square Metal Tubes, ERW steel pipe, large-diameter thick wall square rectangular pipe, LSAW steel pipe, spiral steel pipe, ZAM steel pipes,seamless steel pipe, stainless steel pipe, galvanized coil, PPGI coils and ZAM steel coil.

Tips for Proper Installation of Square Metal Tubes

Proper installation of square metal tubes is essential to ensure structural integrity and longevity. Here are some tips to consider:

1. Prepare the installation area by clearing debris and ensuring a level surface.

2. Use appropriate fasteners and connectors for secure connections.

3. Consider using protective coatings or finishes to prevent corrosion.

4. Follow manufacturer guidelines and recommended installation techniques.

5. Seek professional assistance if needed, especially for complex projects.

Applications and Uses of Square Metal Tubes

Square metal tubes find applications in various industries and projects. They are commonly used in construction for framing, support structures, and handrails. Square tubes are also used in the automotive industry for roll cages and chassis components. Additionally, they are utilized in furniture manufacturing, shelving systems, and machinery frames. The versatility of square metal tubes makes them suitable for both decorative and functional purposes.

AIRPORT VENUES

Black high-frequency welded pipes are indispensable in airport venue buildings,Black high-frequency welded pipes are indispensable in the airport venue buildings. This is our cooperation project Beijing Daxing International Airport

EXPO VENUES

2020 Dubai World Expo venue,The 2020 Dubai World Expo venue is one of the projects we participate in

BRIDGE CONSTRUCTION

Hong Kong-Zhuhai-Macao Bridge,Our products are involved in the construction of bridges. It is a bridge and tunnel project connecting Hong Kong, Zhuhai, Guangdong and Macao in China.

BUILDING CONSTRUCTION

SINGAPORE GOOGLE BUILDING,From 2018 to 2019, we provided steel pipes with hollow section profiles for the construction of Google building in Singapore

GREENHOUSE CONSTRUCTION

From 2017 to 2018, we provided 75000 tons of steel pipe products for the green house of the million feidan land improvement project in Egypt.

CBD business district building

From 2019 to 2020, we provided our steel pipe products for the building development of CBD business district buildings in Cairo, Egypt

THEATER CONSTRUCTION

Located in the west of Tiananmen Square in central Beijing, the National Grand Theatre is the largest theater complex in Asia.

High grade villa building

In 2018, we provided steel pipe products for Dubai Hill high-end villa construction project

Comparison between 3x3 and 4x4 Square Tubes

When choosing between 3x3 and 4x4 square tubes, several factors come into play. The primary difference lies in their size and load-bearing capacity. A 4x4 square tube has a larger cross-section, providing higher strength and stability compared to a 3x3 square tube. The choice depends on the specific application and the required load-bearing capacity.

Maintenance and Care for Square Metal Tubes

Regular maintenance and care can extend the lifespan of square metal tubes. It is important to keep them clean and free from debris that may cause corrosion. Regular inspections should be conducted to identify any signs of damage, such as rust or cracks. Prompt repairs or replacements should be made to avoid compromising the structural integrity of the tubes.

Unless there is a special explanation, we provide each of our customers with comprehensive consideration before product transportation. Firstly, in order to reduce oxidation, we will oil or paint the steel pipe products. Secondly, whether it is packaged or bulk cargo customers, we will wrap the products to prevent damage in the middle. Thirdly, we use our own fleet for transportation, And track and inspect the goods in the whole process to ensure that the products arrive at the designated port accurately. Fourth, we provide each customer with a customer specialist to deal with pre-sales, in-sales and after-sales problems

- 1. 100% after-sales quality and quantity assurance.

- 2. Professional sales manager quickly reply within 24 hours.

- 3. Large Stock for regular sizes.

- 4. Free sample 20cm high quality.

- 5. Strong produce capability and capital flow.

- 6. Small order accepted.

- 7. Brand name raw material

- 8. Support OEM or ODM

- 9. 22 years Manufacturing experience

- 10. It can manufacture steel pipes of different projects and standards in the world

- 11.Yuantai has a standing stock of more than 200000 tons, and the annual shipment specification is: 20*20*1.0—1000*1000*50mm,20*30*1.0—800*1200*50mm,Φ 219— Φ 3620mm,The black, hot-dip galvanized rectangular pipe and spiral welded pipe made of q195-q460 have an existing capacity of nearly 5 million tons.After the completion of the new base in Tangshan, the total production capacity will reach 10 million tons.

Square metal tubes are versatile and durable structural components used in various applications. They offer numerous advantages, including strength, stability, and resistance to corrosion. The choice between 3x3 and 4x4 square tubes depends on the specific requirements of the project. Proper installation, maintenance, and care are crucial for ensuring the longevity and performance of square metal tubes.

Are square metal tubes suitable for outdoor applications?

Yes, square metal tubes are resistant to corrosion and are suitable for both indoor and outdoor applications.

Can square metal tubes be welded together?

Yes, square metal tubes can be easily welded together, allowing for seamless connections in structural projects.

What materials are square metal tubes made from?

Square metal tubes are commonly made from materials such as steel, aluminum, stainless steel, and brass.

What are the advantages of using square metal tubes over round tubes?

Square metal tubes offer enhanced stability, load-bearing capacity, and ease of connection compared to round tubes.

How do I choose the right size of square metal tube for my project?

The size of the square metal tube should be selected based on the required load-bearing capacity and the specific project requirements. Consult with experts to make the best choice.