erw mild steel tube

group nameERW steel pipe

-

Min Order5 ton

brand nameYuantai Derun Steel Pipe Manufacturing Group

modelerw tube

payment methodL/C, T/T

-

update timeSat, 21 Sep 2024 11:25:13 GMT

Paramtents

Thickness 0.5- 16 mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN10210,EN10219,ISO9000,AST

Surface Treatment REQUEST

Tolerance as required

Length 0.5-26.5M according to client requirement

Delivery Time 7-30 Days

Packging & Delivery

Min Order5 ton

Briefing

Detailed

ERW Mild Steel Tube

Complete Types Of ERW Mild Steel Tube For You

More ERW Mild Steel Tube Sizes For You

|

Shape

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

ERW square tube

|

10*10-200*200

|

0.5-16

|

0.5-26.5

|

|

ERW rectangular tube

|

10*15-100*300

|

0.5-16

|

0.5-26.5

|

|

ERW round tube

|

10.3-609

|

0.5-16

|

0.5-24

|

ERW irregular tube | Customized | Customized | Customized |

More Coatings For You

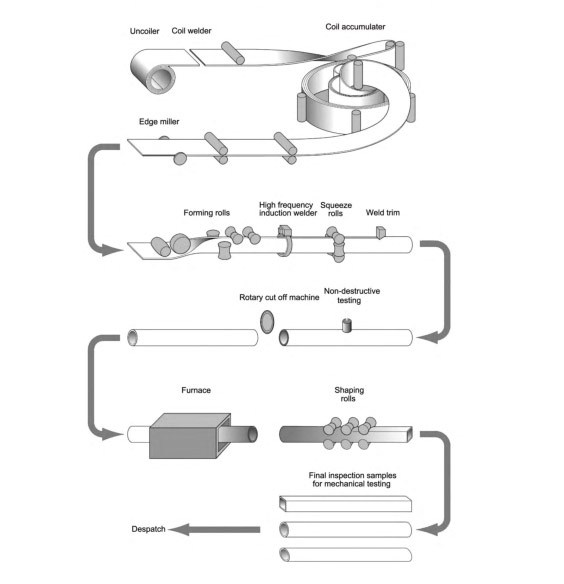

ERW Steel Tube Making Process

Strict Layer By Layer Inspection

Authoritative Certification

FAQ

You need a product

You May Like

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash