Discover the Best in Schedule 40 Carbon Steel Pipes - Unmatched Quality, Versatility, and Competitive Pricing.

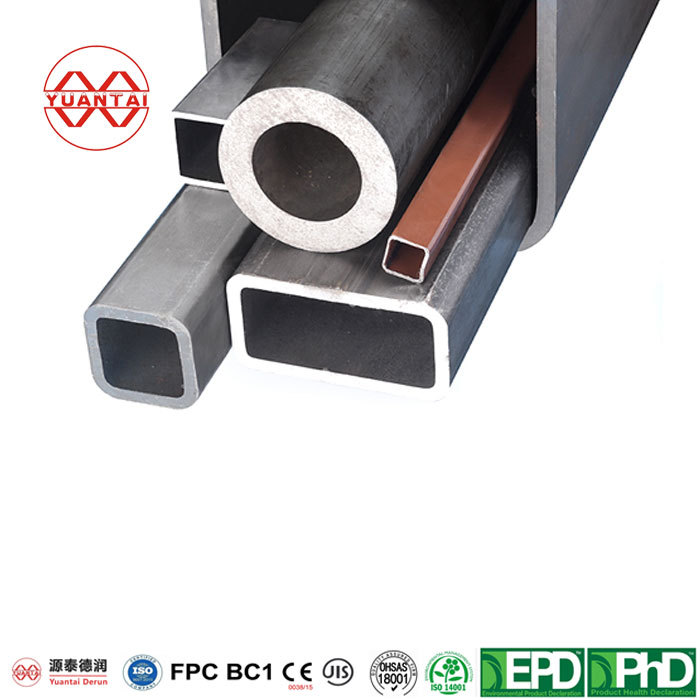

Schedule 40 carbon steel pipe a53 seamless steel pipe

When it comes to piping systems, it is essential to choose the right materials that offer durability, reliability, and performance. Schedule 40 seamless carbon steel pipes are widely used in various industries due to their exceptional properties. In this article, we will delve into the features, benefits, and applications of schedule 40 seamless carbon steel pipes. We will also explore the production process, comparisons with ASTM A53 seamless steel pipes, and tips for selecting the right supplier.

Understanding Schedule 40 Seamless Carbon Steel Pipe

What is a Schedule 40 Seamless Carbon Steel Pipe?

Schedule 40 seamless carbon steel pipe refers to a specific type of pipe that is made from carbon steel and does not have any welded seams. This type of pipe is known for its smooth interior and exterior surfaces, which allow for efficient flow and minimal pressure drop. Schedule 40 refers to the pipe's wall thickness, indicating its strength and capacity to withstand high pressures.

Advantages of Schedule 40 Seamless Carbon Steel Pipe

1.High Strength: Schedule 40 seamless carbon steel pipes are known for their exceptional strength, making them suitable for demanding applications.

2.Smooth Flow: The absence of welded seams ensures a smooth interior surface, minimizing friction and maintaining an efficient flow of fluids.

3.Resistant to Corrosion: Carbon steel pipes are highly resistant to corrosion, making them suitable for both indoor and outdoor applications.

4.Versatility: Schedule 40 seamless carbon steel pipes can be used for various purposes, including plumbing, oil and gas transportation, and structural applications.

Uses and Applications of Schedule 40 Seamless Carbon Steel Pipe

Schedule 40 seamless carbon steel pipes find applications in a wide range of industries. Some common uses include:

1.Plumbing systems in residential, commercial, and industrial buildings.

2.Oil and gas transportation pipelines.

3.Steam and water supply systems.

4.Structural support in construction projects.

5.Heat exchangers and condenser tubes in power plants.

6.Automobile manufacturing and exhaust systems.

Schedule 40 carbon steel pipe advantages and features

Steel pipe orifice leveling

Yuantaiderun steel pipe orifice is very flat,Tight weld

The steel pipe surface is smooth

The surface of the steel pipe shall be smooth without burrs

No joint, no cushion bar

There is no joint and backing bar in the finished steel pipe

Raw materials guarantee

Large factory direct supply

Each large diameter seamless steel pipe 100% complies with international standards

Each pipe is inspected layer by layer

OEM&ODM&OBM

Yuantai derun accepts OEM,ODM,OBM

Features and Specifications of Schedule 40 Seamless Carbon Steel Pipe

Yuantai Derun is one of astm a53 schedule 40 seamless steel pipe factory whice can produce all kinds of seamless steel pipe,low price,high quality.And we accept OEM/ODM/OBM.We accept mass customization

Specification sheet of astm a53 schedule 40 seamless steel pipe

| Product Name |

astm a53 schedule 40 seamless steel pipe |

| Size |

OD: 21.3mm-820mm |

| Wall Thickness: 2mm-50mm |

| Length: 3-12m or according to clients` requirements. |

| Steel material |

GrA, Gr B, GrC, SS330, S275J0H; S355JR ; S355J0H; S355J2H.SS400,S235JR,S235JO,S235J2,S420,S460 |

| Standard |

API 5L,ASTM A53/A106/A500/A501,EN10219, EN10210, GB/T6728, GB/T3094, GB/T3091,JIS G3466,GB/T9711 |

| Usage |

petroleum, chemical industry, steel, machinery, military industry, aerospace and so on |

| Ends |

1) Plain |

| 2) Beveled |

| 3) Thread |

| End protector |

1) Plastic pipe cap |

| 2) Iron protector |

| Surface Treatment |

galvanized or request |

| Technique |

seamless |

| Type |

thick wall |

| Section Shape |

Round |

| Inspection |

With Hydraulic Testing, Eddy Current , Infrared Test |

| Package |

1) Bundle, |

| 2) In Bulk |

| 3) Bags |

| 4) Clients' Requirements |

| Delivery |

1) Container |

| 2) Bulk carrier |

| Port of Shipment |

Xingang, Tianjin,China |

| Payment |

L/C T/T |

Schedule 40 seamless carbon steel pipes are available in various dimensions and sizes, making them suitable for different applications. The standard sizes range from 1/8" to 24" in nominal diameter, with a range of schedules to choose from based on the required pressure rating.

Schedule 40 seamless carbon steel pipes are primarily made from carbon steel, which contains iron and carbon as the main elements. Additionally, small amounts of other elements like manganese, silicon, and sulfur may be present to enhance specific properties.

The pressure ratings of schedule 40 seamless carbon steel pipes vary depending on the dimensions and sizes. These pipes can withstand high pressure levels, making them suitable for demanding applications that require efficient fluid transportation.

Benefits of Using Schedule 40 Seamless Carbon Steel Pipe

Schedule 40 seamless carbon steel pipes are known for their durability and strength. They can withstand high pressures and harsh operating conditions without compromising their structural integrity, ensuring long-term performance.

Carbon steel pipes are inherently resistant to corrosion, making them suitable for a wide range of applications. With proper maintenance and care, schedule 40 seamless carbon steel pipes can last for many years, even in corrosive environments.

Compared to other materials, schedule 40 seamless carbon steel pipes offer excellent cost-effectiveness. They have a long service life, require minimal maintenance, and are readily available, making them a cost-efficient choice for various industries.

ASTM A53 Seamless Steel Pipe and Schedule 40 Seamless Carbon Steel Pipe

Understanding ASTM A53 Standards

ASTM A53 is a widely recognized standard for steel pipe specifications in the United States. It covers both seamless and welded steel pipes, with different grades and types suitable for various applications. ASTM A53 seamless steel pipes meet specific requirements for mechanical properties, chemical composition, and dimensions.

Seamless Carbon Steel Pipe vs. ASTM A53 Seamless Steel Pipe

While schedule 40 seamless carbon steel pipes are primarily made from carbon steel, ASTM A53 seamless steel pipes may have additional alloying elements to enhance specific properties. It is important to consider the intended application and requirements when choosing between the two options.

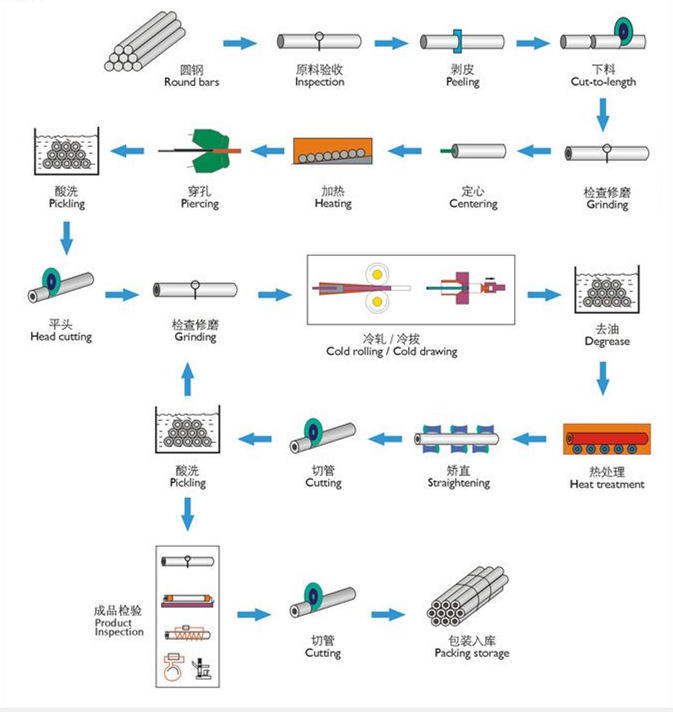

The Process of Producing Schedule 40 Seamless Carbon Steel Pipe

Raw Material Selection

The production of schedule 40 seamless carbon steel pipes starts with the selection of high-quality raw materials. The choice of carbon steel ensures the pipes' strength and resistance to corrosion, while proper sourcing and testing of the raw materials ensure consistent quality.

Pipe Manufacturing

The manufacturing process involves heating the raw material, followed by seamless pipe formation through extrusion or rotary piercing methods. The pipes are then heat-treated to enhance their mechanical properties, such as strength and durability.

Quality Control

To ensure the highest standards, schedule 40 seamless carbon steel pipe manufacturers implement stringent quality control measures. These include non-destructive testing, dimensional checks, and visual inspections to identify and eliminate any defects or imperfections.

Strict product inspection

Each steel pipe must pass the inspection layer by layer. Only the products that pass the inspection can leave the factory. Never let an unqualified product flow into the market

Choosing the Right Schedule 40 Seamless Carbon Steel Pipe Supplier

Reputation and Experience

When selecting a supplier for schedule 40 seamless carbon steel pipes, it is crucial to consider their reputation and experience in the industry. A reputable supplier with extensive experience is more likely to provide high-quality products and reliable services.

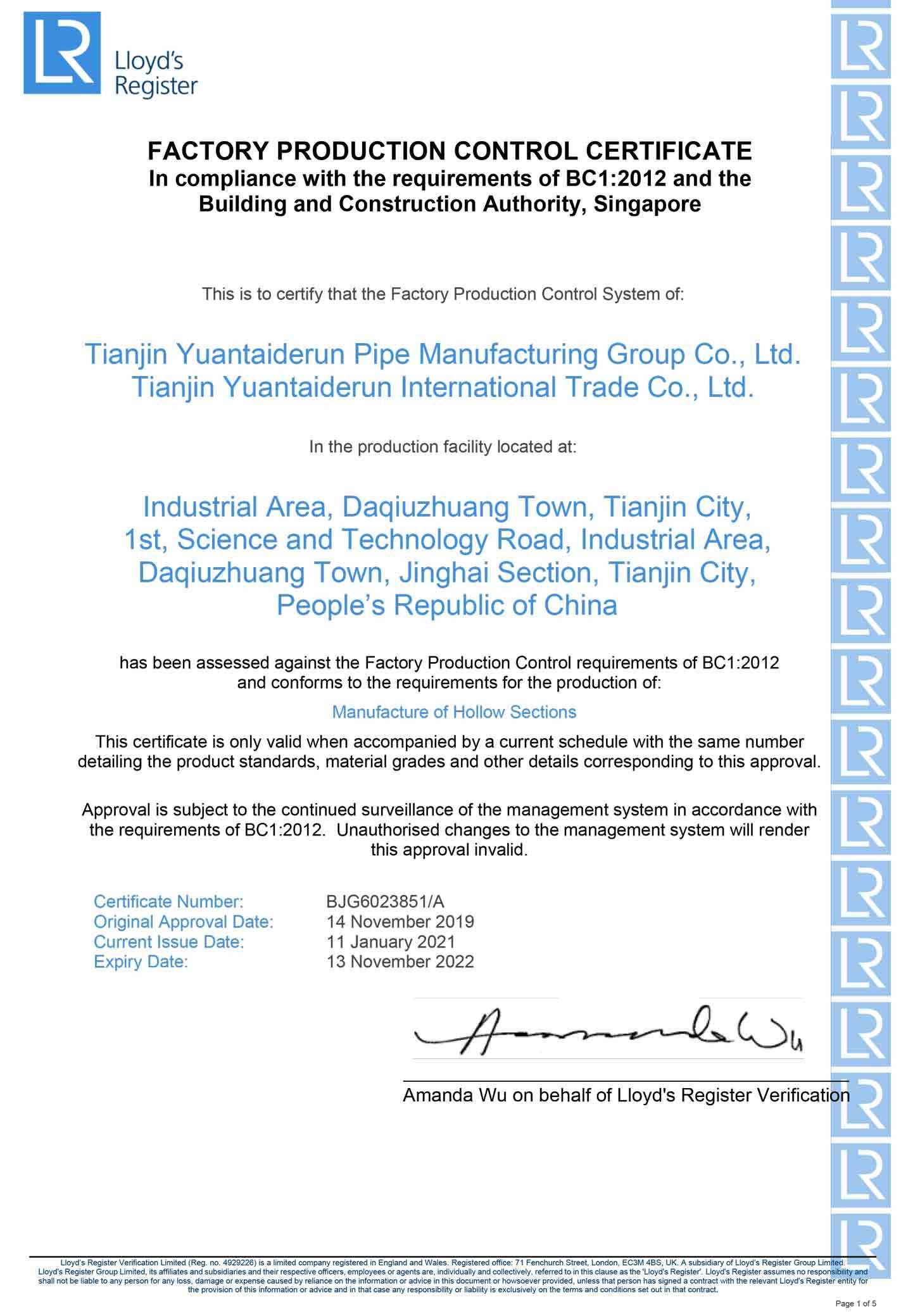

Certification and Compliance

Ensure that the supplier is certified and complies with relevant industry standards and regulations. This ensures that the schedule 40 seamless carbon steel pipes supplied meet the necessary quality and safety requirements.

Customer Service

Good customer service is essential when choosing a supplier. Look for a supplier that is responsive, provides timely deliveries, and offers excellent after-sales support, including technical assistance and warranty options.

BC1

FACTORY PRODUCTION CONTROL CERTIFICATE,ln compliance with the requirements of BC1:2012 and the Building and Construction Authority, Singapore

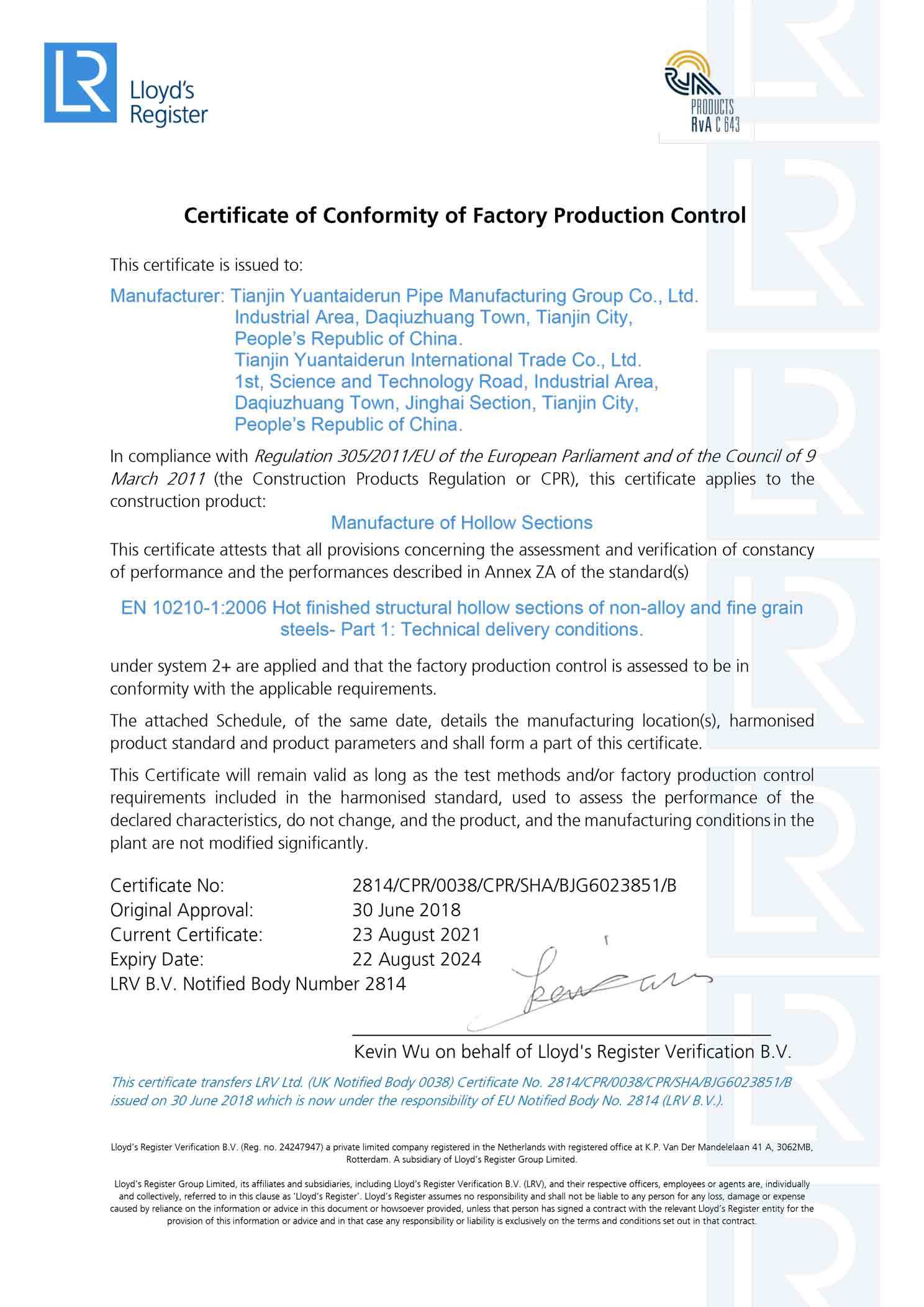

EN10210

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

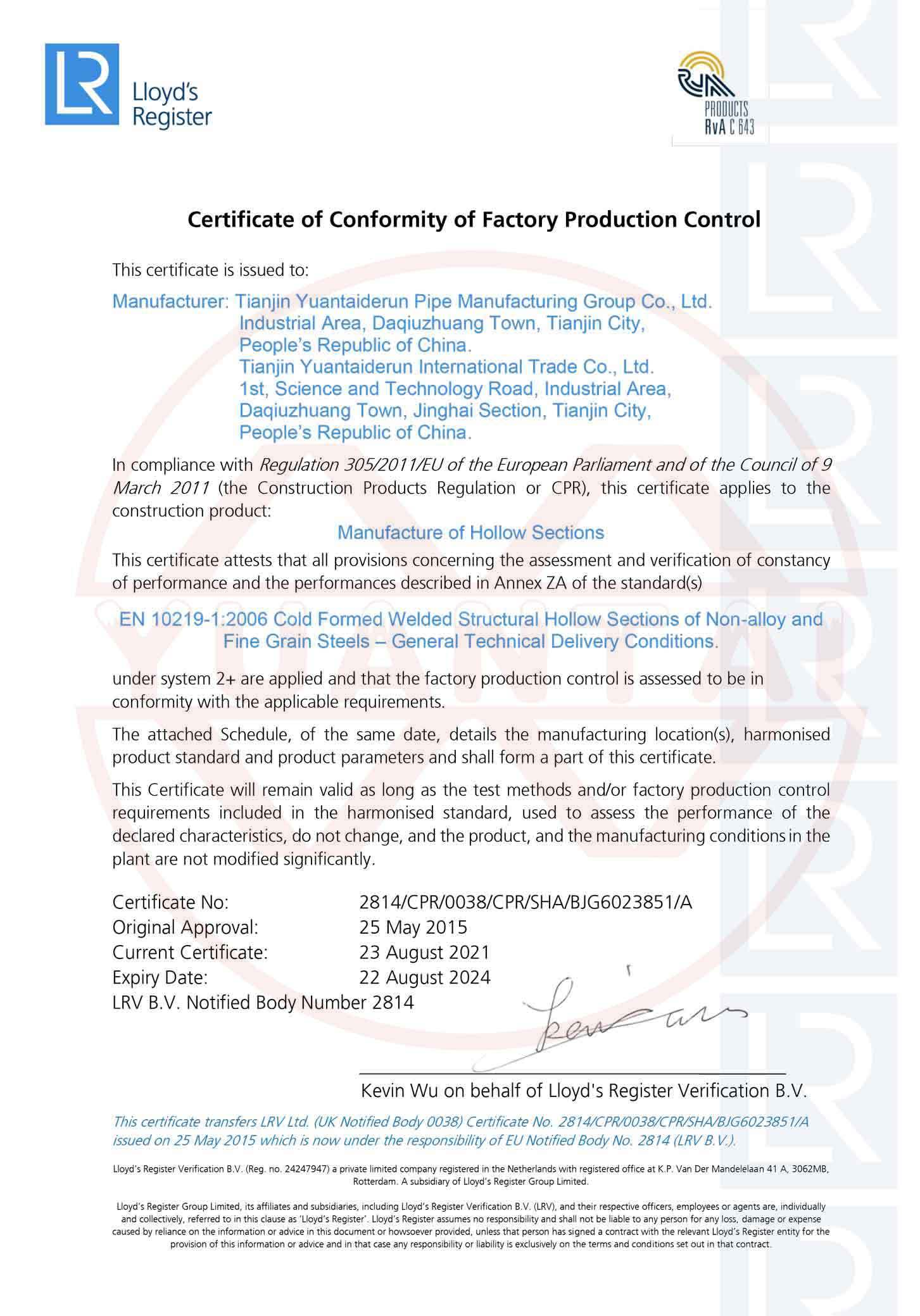

EN10219

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

BV

This certficate is issued to attest that Bureau Vveritas Marine & Ofishore has perormed, at the above company's request and in compliance withthe requirements of NR320,a satisfactory assessment of the manudacturing facilities and associated quality procedures related to the ranrge of therecogniition.

EPD

Environmental Product Declaration

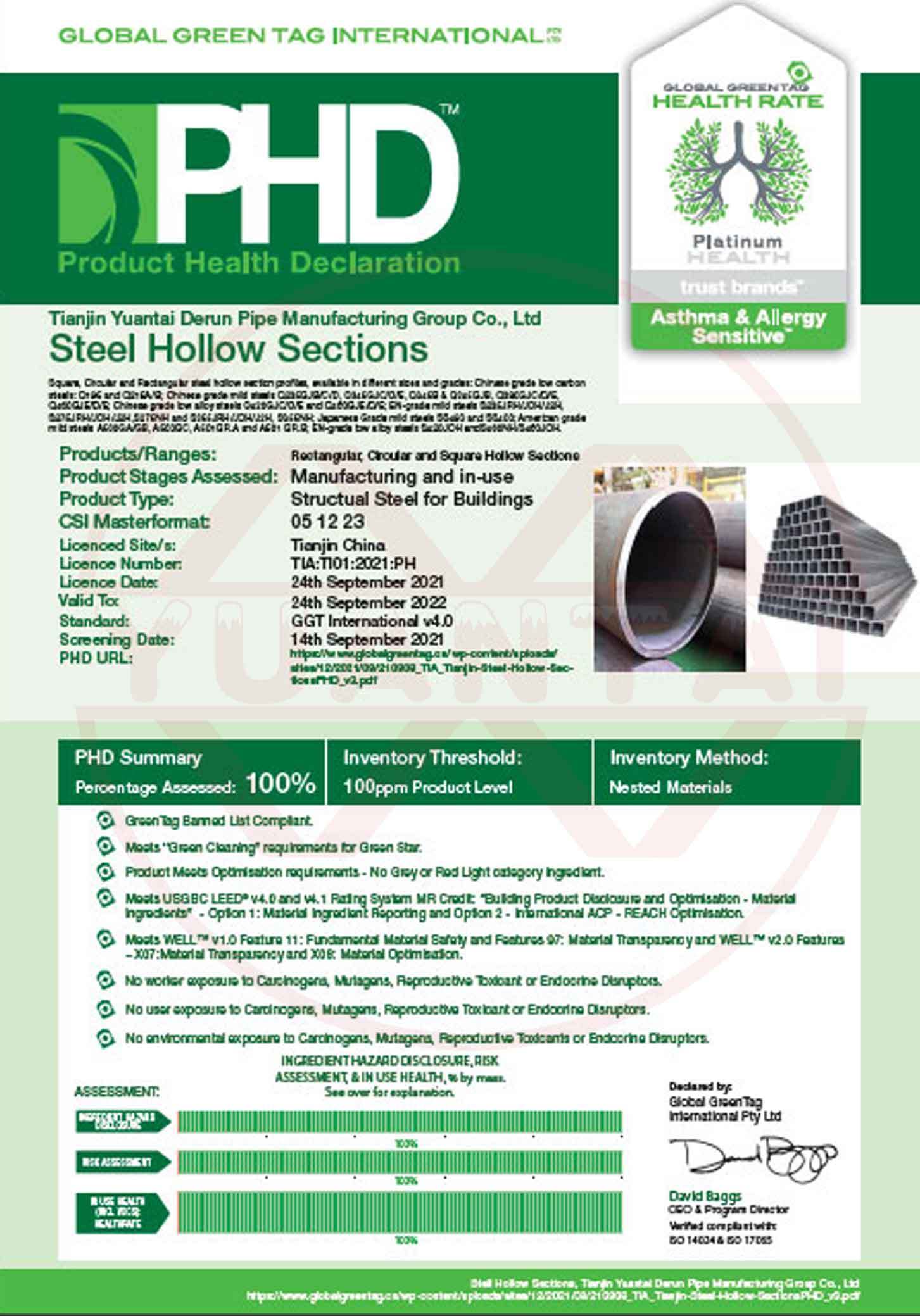

PHD

Product Health Declaration

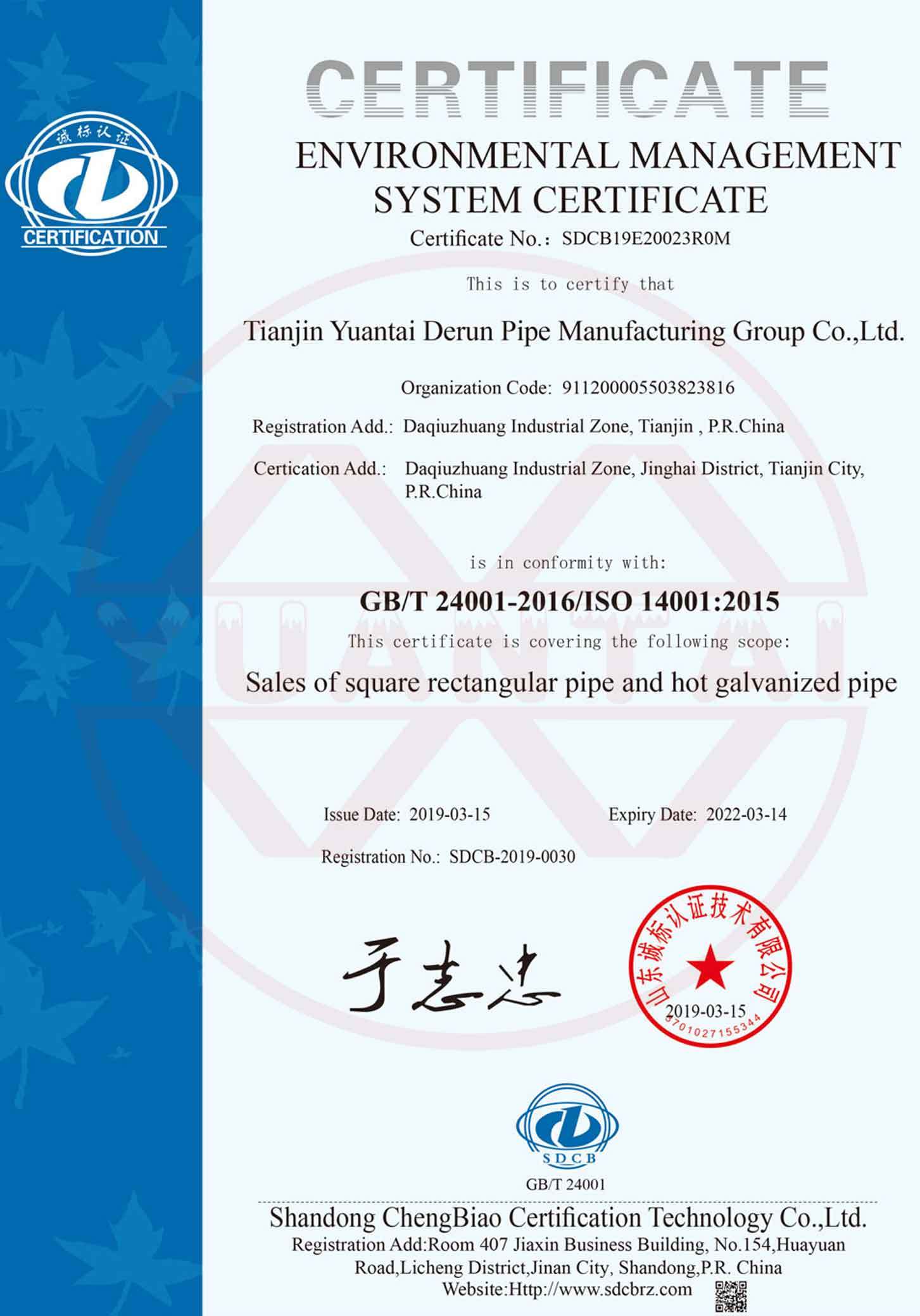

ISO14001(GB/T 24001)

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

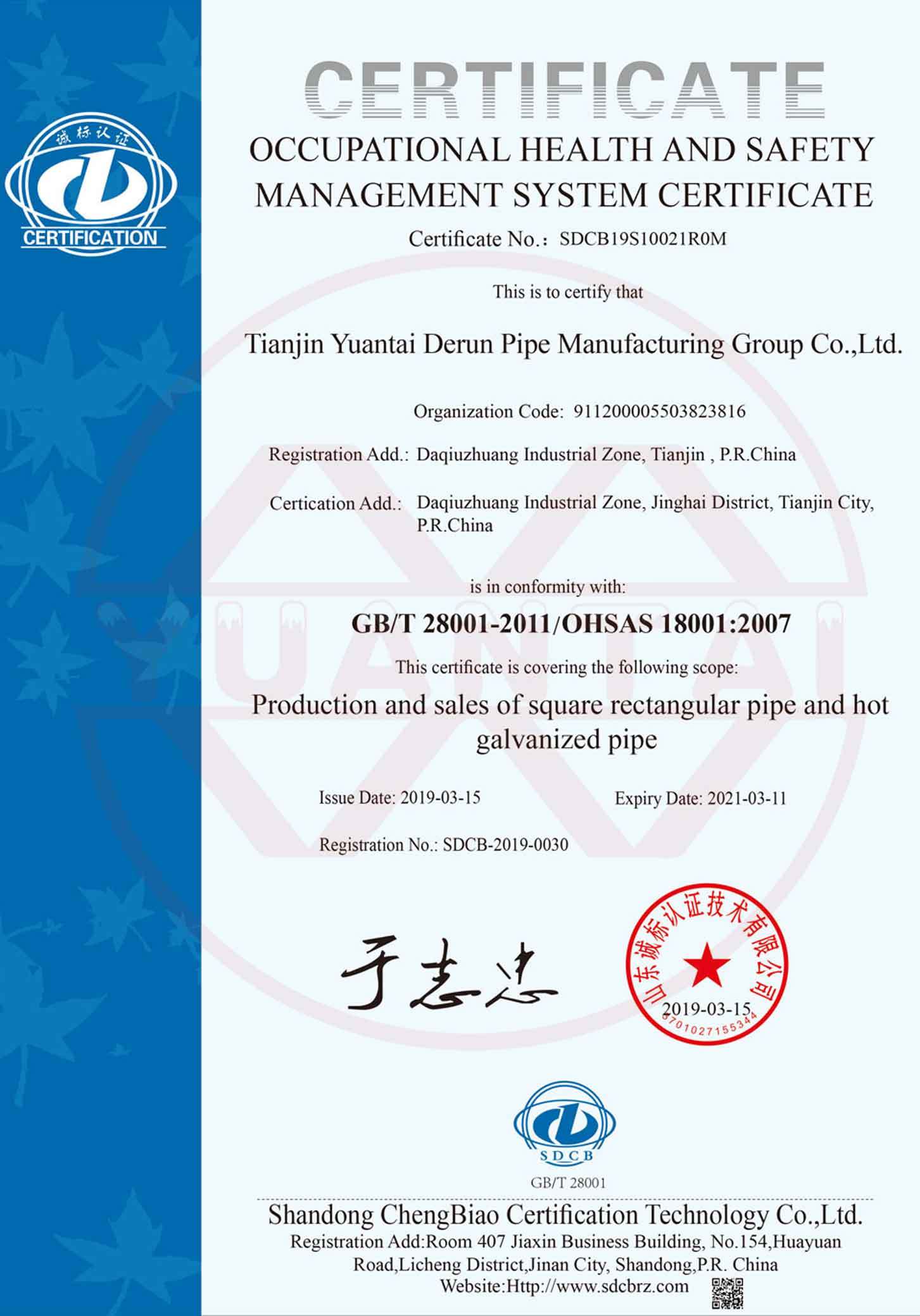

OHSAS 18001(GB/T28001-2011)

OCCUPATIONAL HEALTH AND SAFETYMANAGEMENT SYSTEM CERTIFICATE

ISO9001(GB/T19001)

The production of rectangular pipe and hot-dip galvanized pipe, the sales and service of metal materials, and the quality management system meet the requirements

GB / t19001-2016 / iso9001:2015

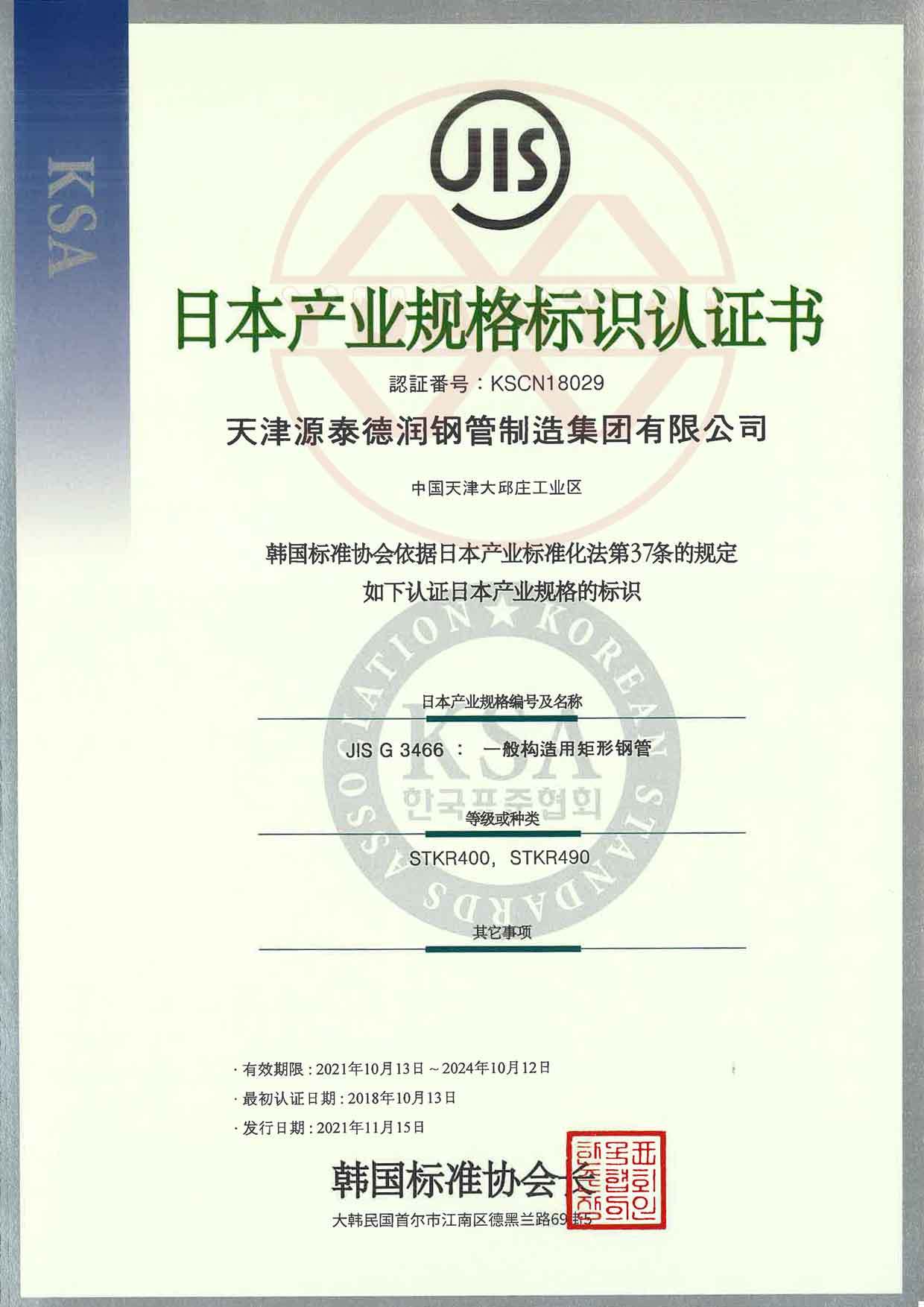

JIS G3466

Jis G 3466 : Carbon steel square and rectangular tubes for general structure meet JIS G3466 standard

Maintenance and Care of Schedule 40 Seamless Carbon Steel Pipe

Regular cleaning and inspections of schedule 40 seamless carbon steel pipes are crucial for maintaining their performance and longevity. Cleaning can involve removing debris and corrosive substances, while inspections help identify any signs of wear, erosion, or damage.

While schedule 40 seamless carbon steel pipes are resistant to corrosion, proper preventive measures can further enhance their longevity. This can include using protective coatings, implementing cathodic protection systems, or controlling the surrounding environment.

Comparison of Schedule 40 Seamless Pipe Dimensions

Please refer to the table below for a comparison of schedule 40 seamless pipe dimensions.

| Size (NPS) | Outside Diameter (mm) | Wall Thickness (mm) |

|---|

| 1/8" | 10.3 | 1.73 |

| 1/4" | 13.7 | 2.24 |

| 3/8" | 17.1 | 2.31 |

| ... | ... | ... |

Schedule 40 seamless carbon steel pipes offer numerous benefits and are widely used in various industries for different applications. Their durability, strength, corrosion resistance, and cost-effectiveness make them a reliable choice. Understanding the production process and selecting the right supplier are essential for obtaining high-quality pipes that meet specific requirements. By following proper maintenance and care practices, the longevity and performance of schedule 40 seamless carbon steel pipes can be significantly enhanced.

1. Can schedule 40 seamless carbon steel pipes be used for high-pressure applications?

Yes, schedule 40 seamless carbon steel pipes can withstand high pressures, making them suitable for a broad range of applications that require efficient fluid transportation.

2. Are schedule 40 seamless carbon steel pipes resistant to corrosion?

Yes, carbon steel pipes, including schedule 40 seamless pipes, are inherently resistant to corrosion. However, proper preventive measures should be taken to further enhance their resistance to corrosive environments.

3. How do I choose the right schedule 40 seamless carbon steel pipe supplier?

Consider the reputation, experience, certifications, and customer service of potential suppliers. A reliable supplier will ensure the delivery of high-quality products and provide excellent support throughout the purchasing process.

4. Can schedule 40 seamless carbon steel pipes be used in plumbing systems?

Yes, schedule 40 seamless carbon steel pipes are commonly used in plumbing systems for residential, commercial, and industrial buildings due to their durability and efficient flow characteristics.

5. What is the difference between schedule 40 seamless carbon steel pipes and ASTM A53 seamless steel pipes?

While schedule 40 seamless carbon steel pipes are primarily made from carbon steel, ASTM A53 seamless steel pipes may have additional alloying elements to enhance specific properties. The choice between the two depends on the intended application and requirements.