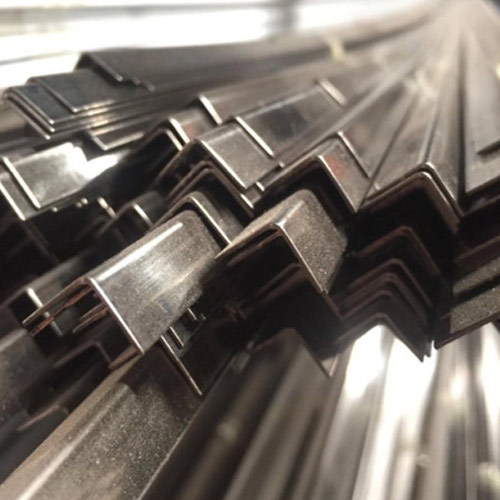

hot rolled steel angle

group namesteel profile

-

Min Order2 ton

brand nameYuantai Derun Steel Pipe Manufacturing Group

modelhot roll steel angle

payment methodL/C, T/T

-

update timeSun, 03 Nov 2024 05:35:04 GMT

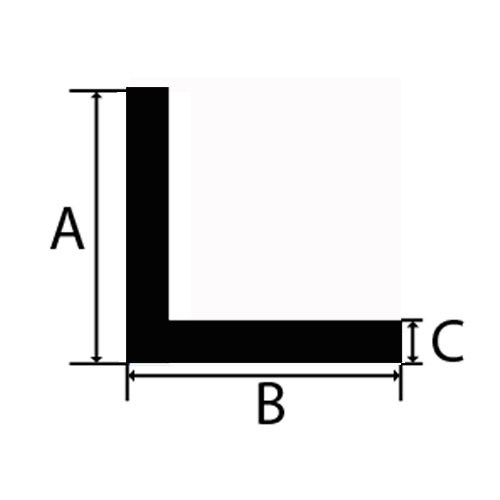

Paramtents

steel grade s275jr/s355jr,etc

Packging & Delivery

Min Order2 ton

Briefing

Detailed

Hot Rolled Steel Angle

Hot Rolled Steel Angle Sizes

Hot Rolled Steel Angle Type

Hot Rolled Steel Angle Price

Hot Rolled Steel Angle Characteristics

Hot Rolled Steel Angle Manufacturing Process

Hot Rolled Steel Angle Surface Treatment

Hot Rolled Steel Angle Application

FAQ:

You need a product

You May Like

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash