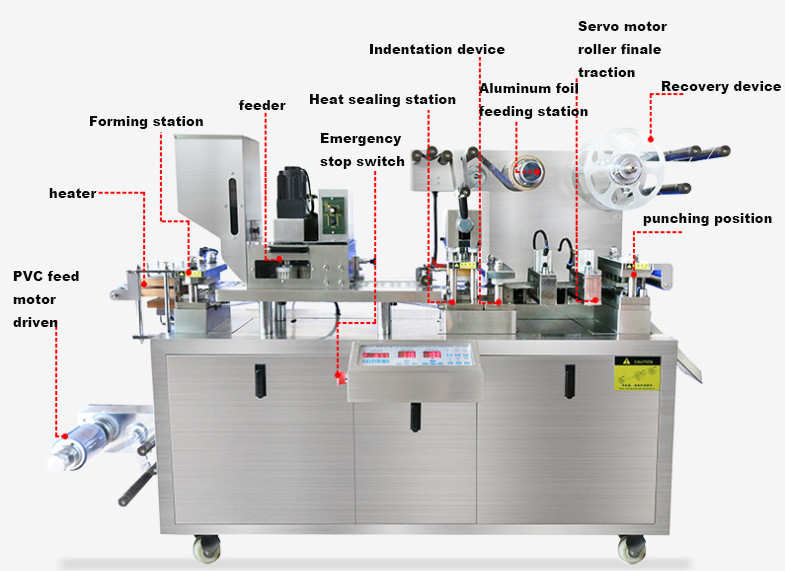

High Quality Medicine Jelly Food Blister Packer Packing Machine

group nameMultifunction packing machine

-

Min Order1 piece

brand nameZQS

modelZQS-2027

payment methodT/T

-

update timeWed, 31 May 2023 18:22:47 GMT

Paramtents

Material 304 Steel

Function Food Medicine Packing

Air Pressure 0.6mPa

Packing Materials PP PVC plate

Packging & Delivery

Min Order1 piece

Briefing

Speed: 360-720 boxes per hours depended on the machine type

Detailed

Model: 350/480 vertical

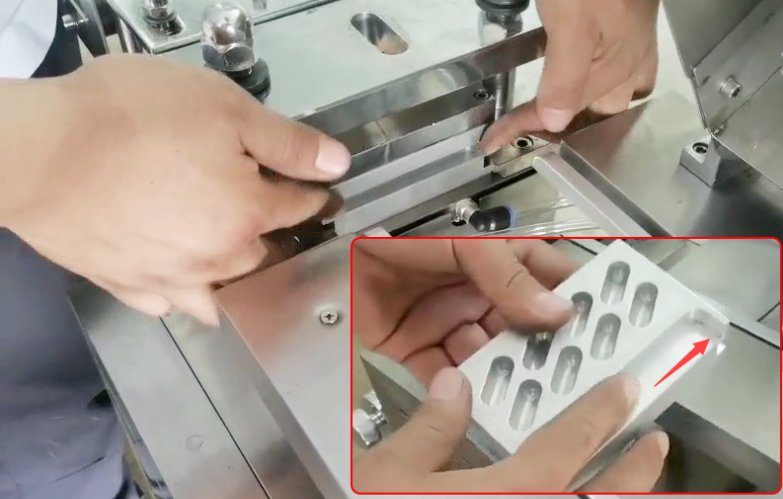

Mold: 6061 food grade aluminum alloy

Vacuum pump: 63/100 pump

Chassis: 304 stainless steel

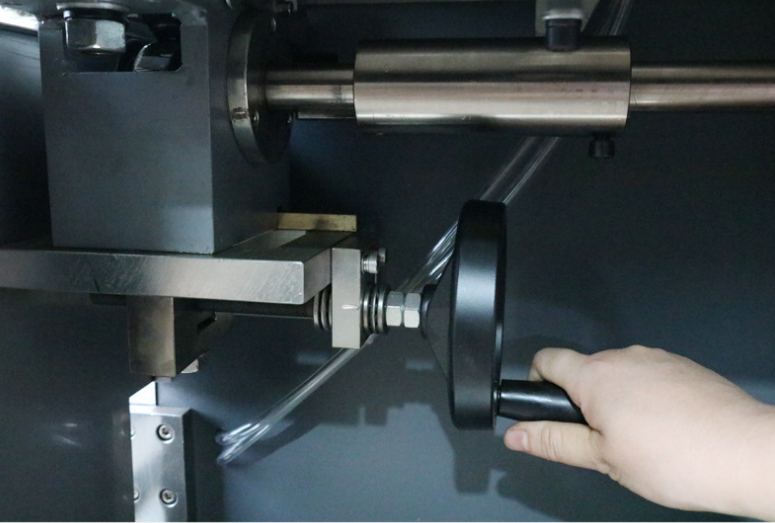

Working air pressure:>0.6Mpa

Film width: 330mm/480mm

Maximum size of vacuum chamber: 400x290x50mm/550x390x50mm

Machine dimensions: 1000x1200x1510mm/1200x1300x1560mm

Work efficiency: 360/720 boxes/hour

Machine weight: 350kg

Advantages :

If you are in food, drugs, or chemical industries, chances are you may not be sure whether to buy a blister packaging machine or not. To make things crystal clear, here are the top benefits of using a blister packaging machine:

Guarantees product integrity: At this point, you can tell that this blister packing is used for very sensitive applications. They include food and drug industries. Blister packs provide an air-tight seal to the products. They won’t be exposed to moisture nor air. In doing so, the end product will retain its quality.

Tamper proof: Lister packages cannot be interfered with by any external physical forces. This also goes a long way in preserving the integrity of the pills and capsules.

Cost-effective: Blister packaging can save you a significant amount of money, especially when you want to cut down on the cost of packing capsules and pills. It is cheaper than plastic packaging.

Accurate dosage: Since the pills and tablets are in their designated packages, maintaining the accuracy of the dosage won’t be a challenge in any way. It will be easy for one to keep track of the drug dosage.

Improves identification: As we have stated, labeling is one of the activities that are highlighted by the blister packing machine process. It ensures that the products are easily identified by their names among other information.

You need a product

You May Like

6YRS Zhongshan Zhiqingsong Automatic Machinery Co.,Ltd

- Nearest port for product export

- GUANGZHOU, SHENZHEN, ZHONGSHAN, HONGKONG

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash