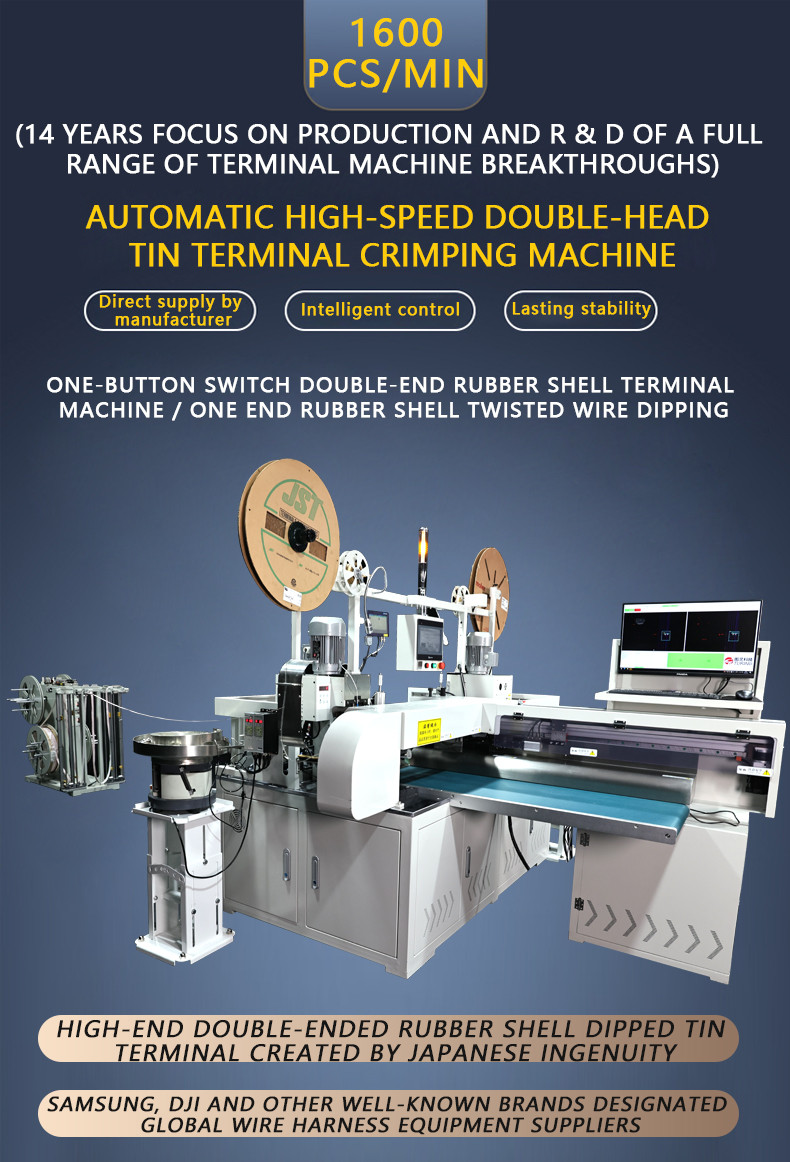

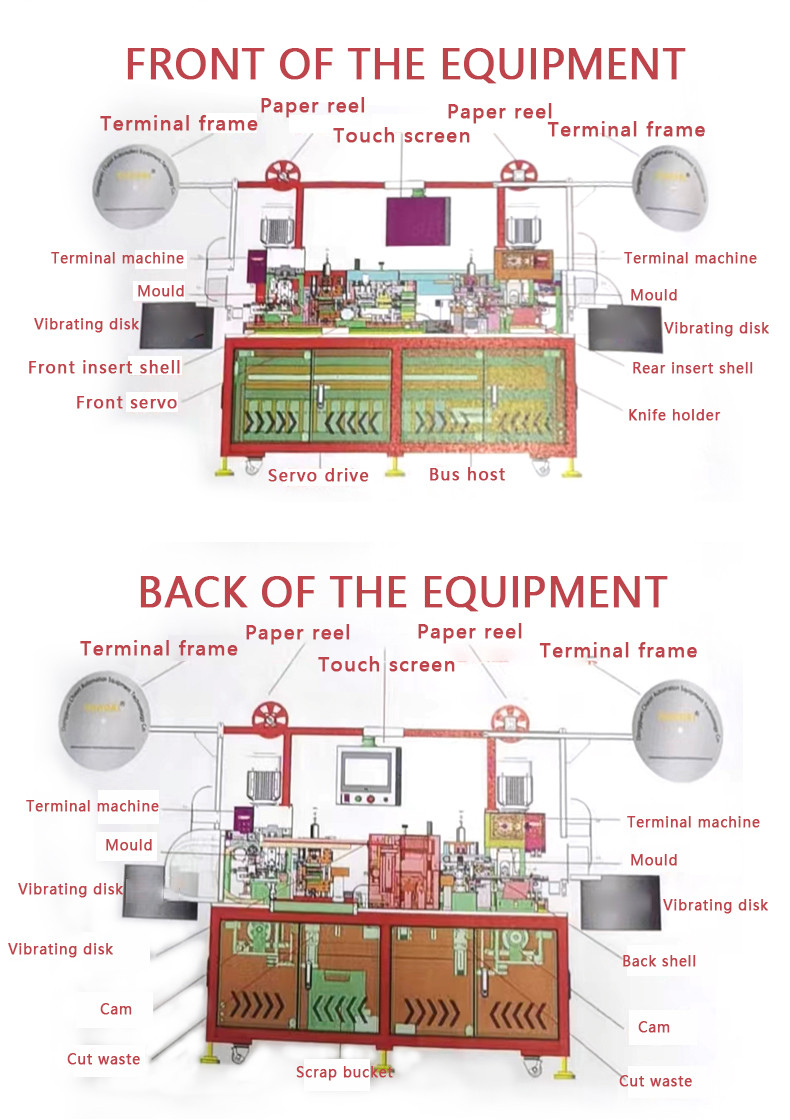

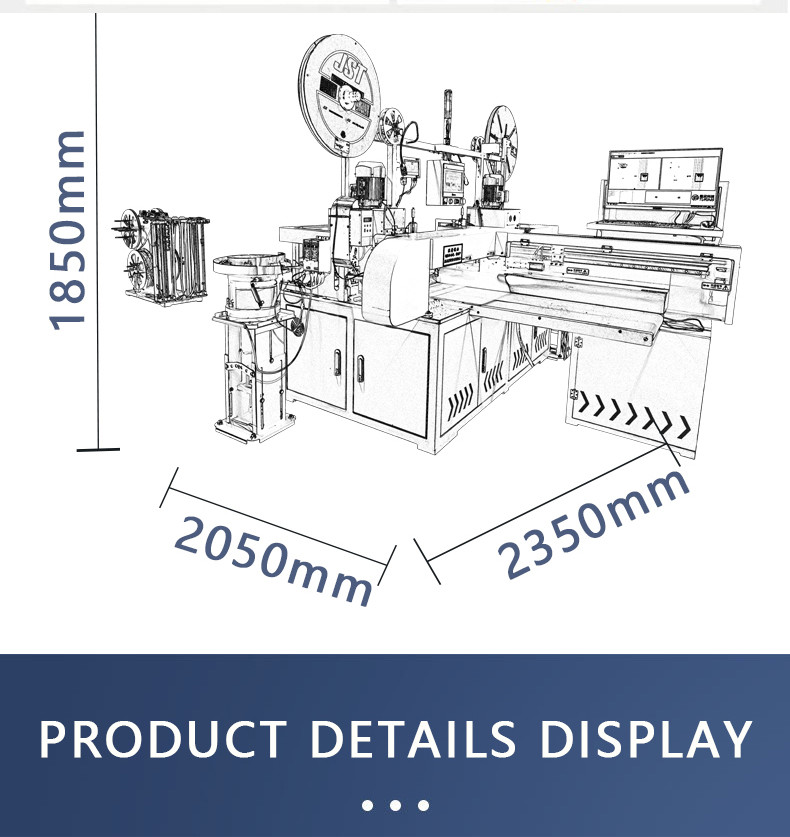

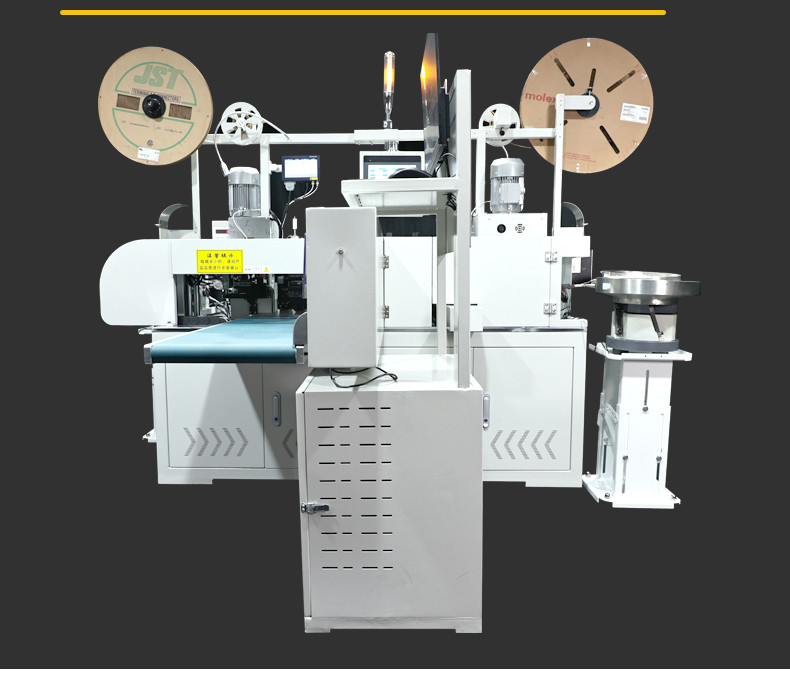

TR-13Z Fully Automatic High-speed Double-head Insert Plastic Shell Tin Dipping Machine

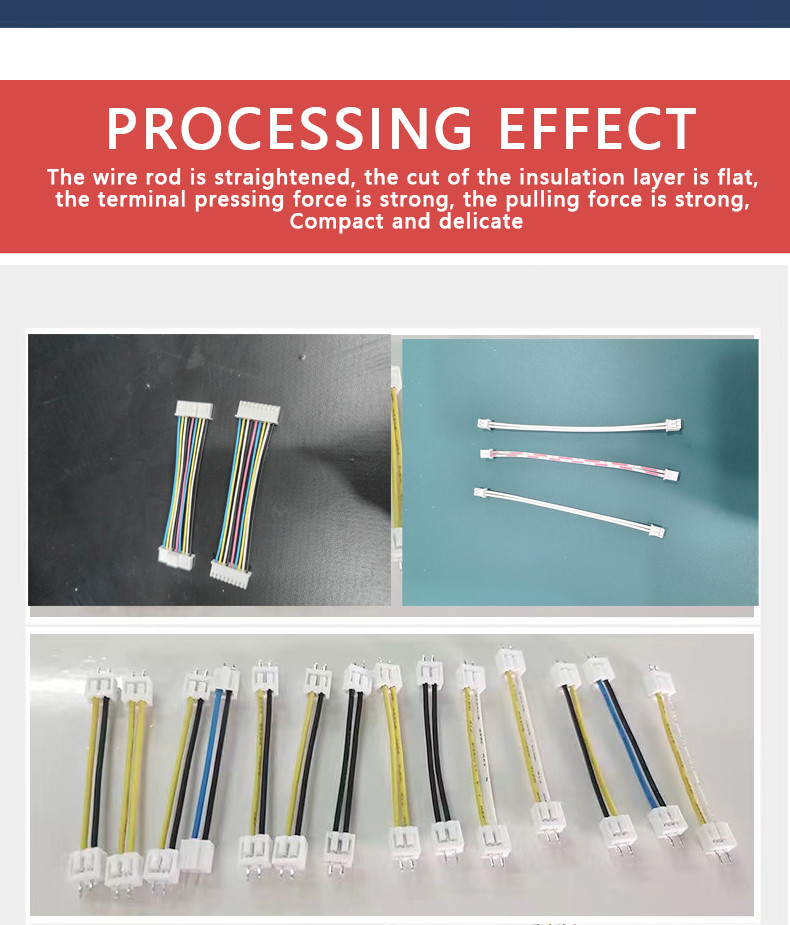

group namePlastic Shell Terminal Crimping Machine

-

Min Order1 piece

brand nameTuring

modelTR-13Z

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 08 Nov 2024 11:34:25 GMT

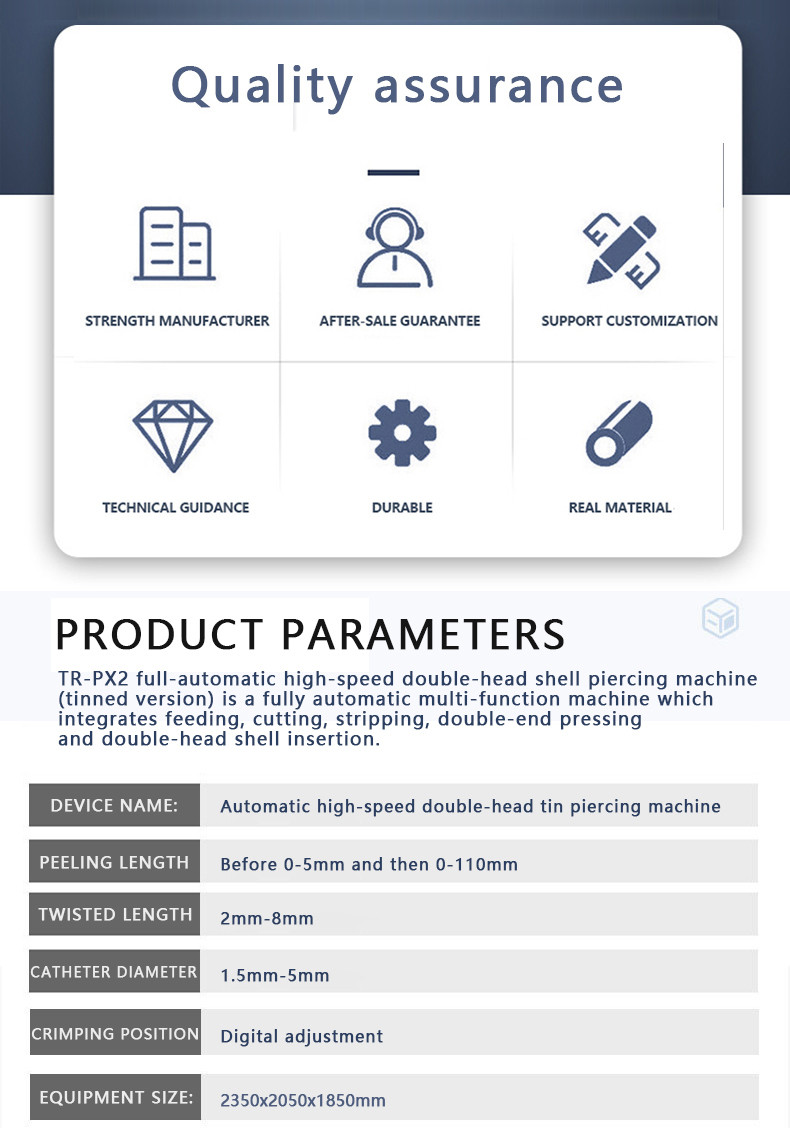

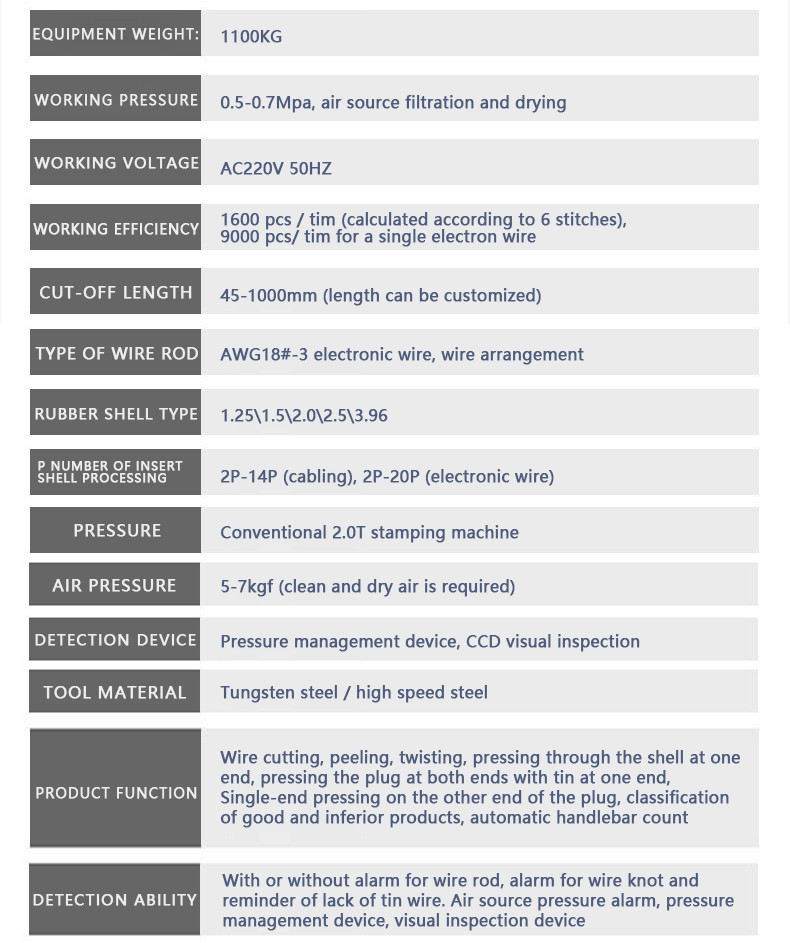

Paramtents

Power AC220V/50HZ,

Application Double end Terminal Machine

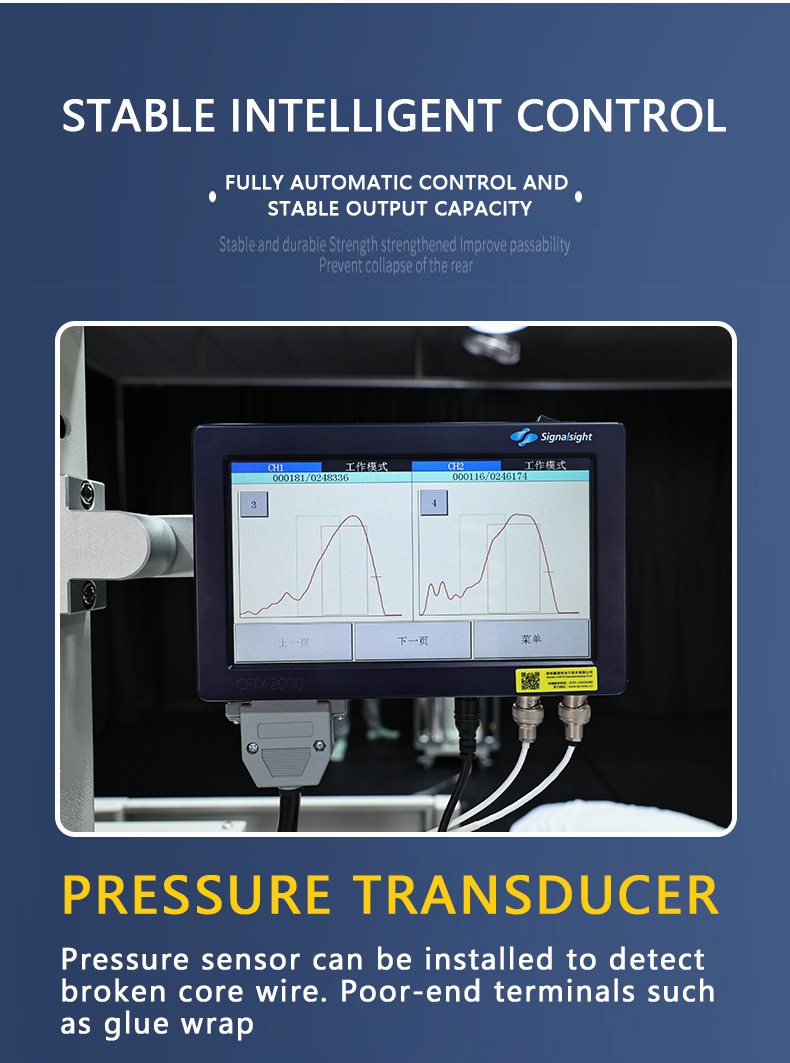

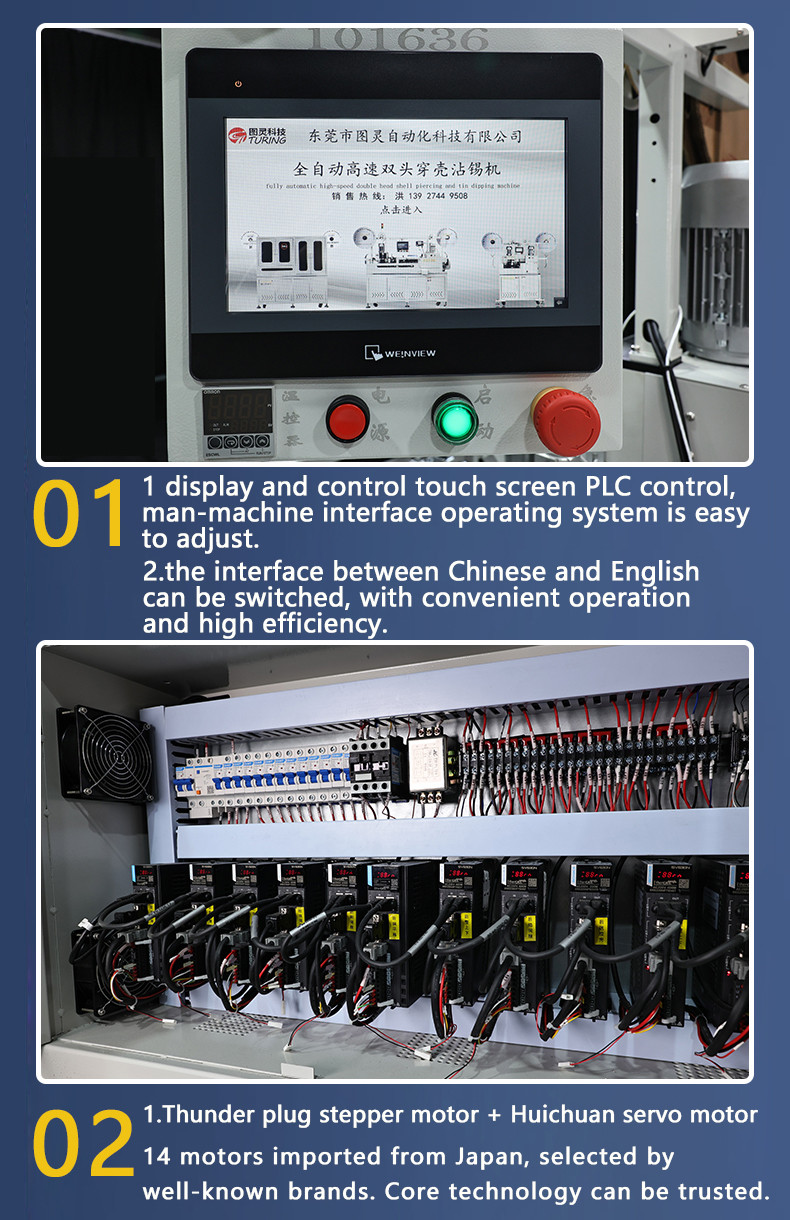

Feature Stable Performance

Warranty 1year

Control Servo and Step motor

Contact Coco 0086-18666170785

Packging & Delivery

Weight1200.00kg / piece

Min Order1 piece

Briefing

Lily +8613715588365

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash