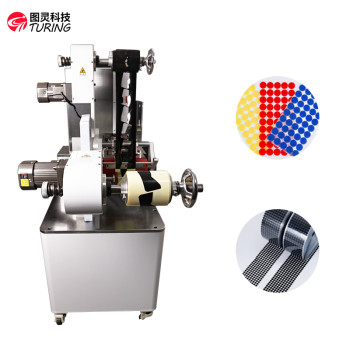

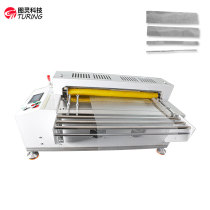

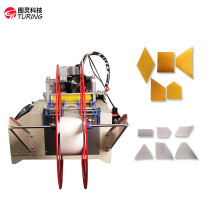

TR-201MS Turing Semi-auto Adhesive Velcro Die Cutting Machine

group nameTape Cutting Machine

-

Min Order1 piece

brand nameTuring

modelTR-201MS

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 08 Nov 2024 04:47:29 GMT

Paramtents

Power AC220V/50HZ,

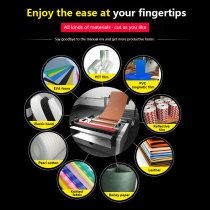

Application Cutting Machine

Feature Stable Performance

Warranty 1year

Contact Coco 0086-18666170785

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash