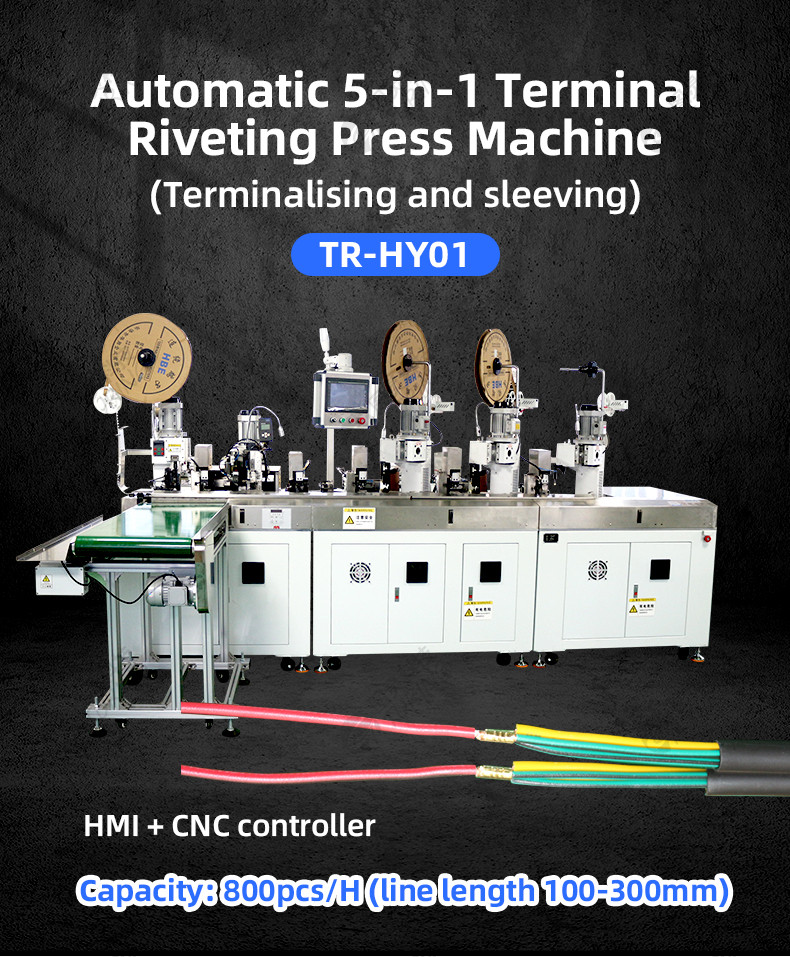

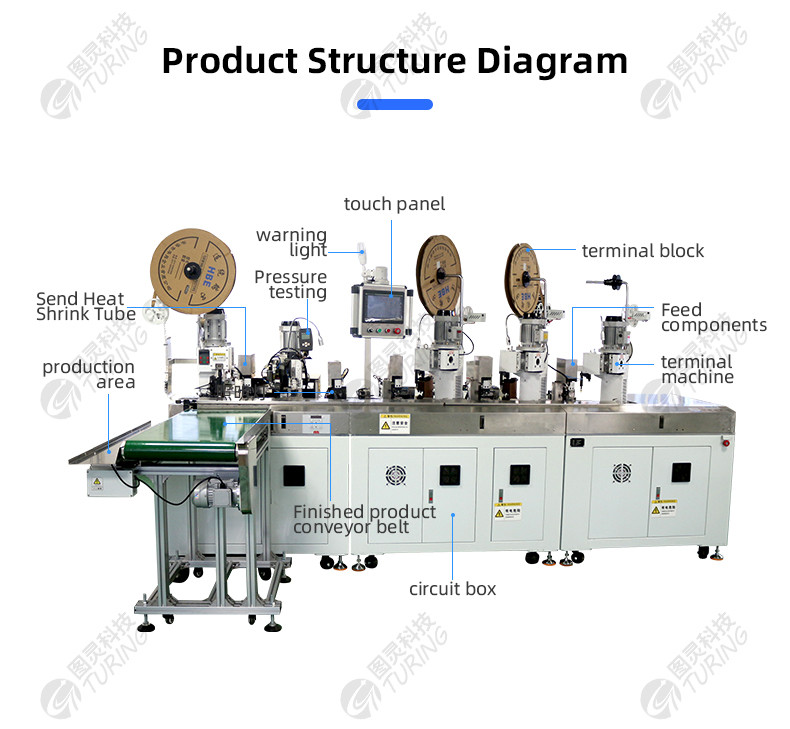

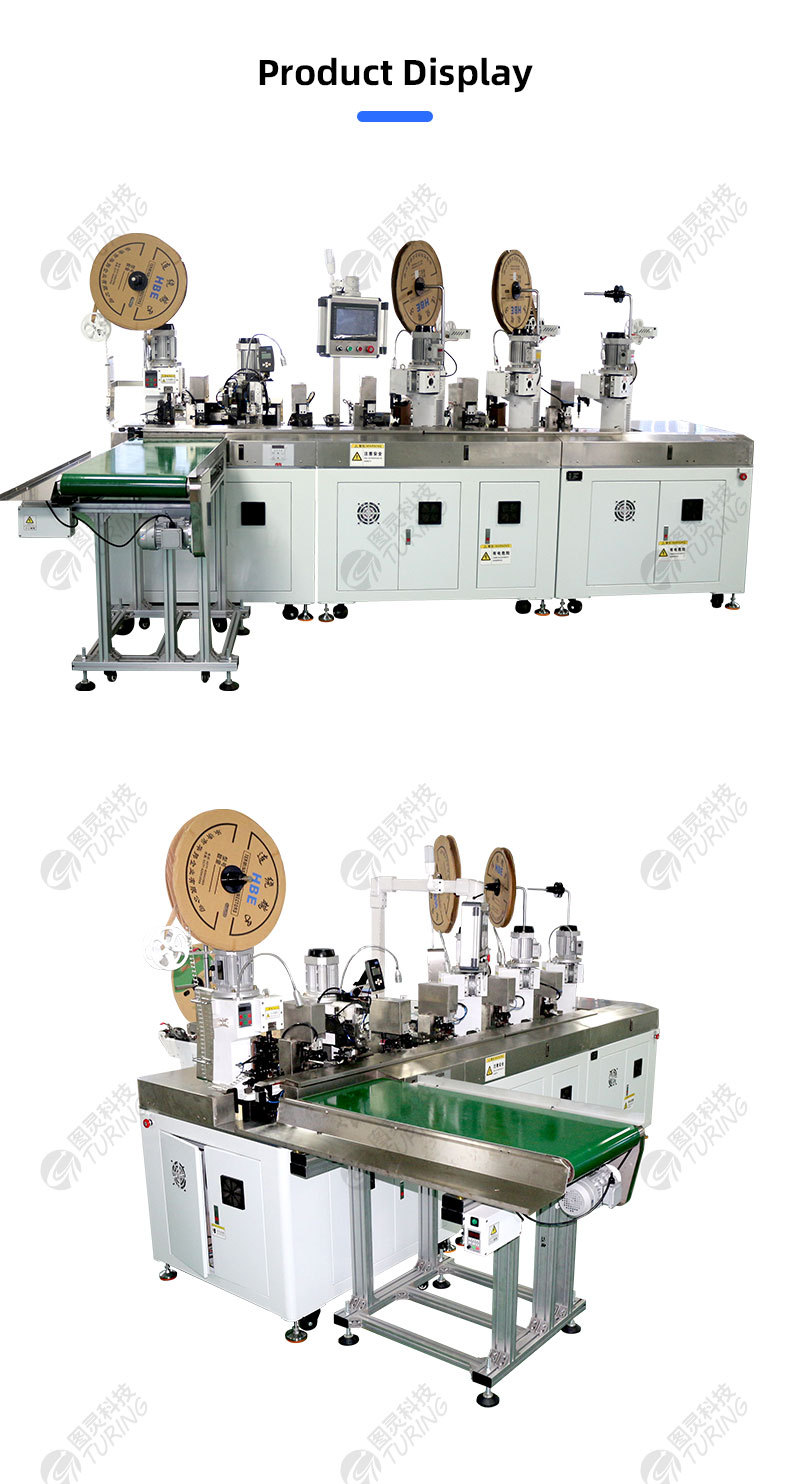

TR-HY01 Automatic 5-in-1 Terminal Riveting Press Machine(Terminalising and sleeving)

group nameSemi-auto Copper Strip Crimping Machine

-

Min Order1 piece

brand nameTuring

modelTR-HY01

payment methodWestern Union, MoneyGram, T/T

-

update timeFri, 08 Nov 2024 08:40:23 GMT

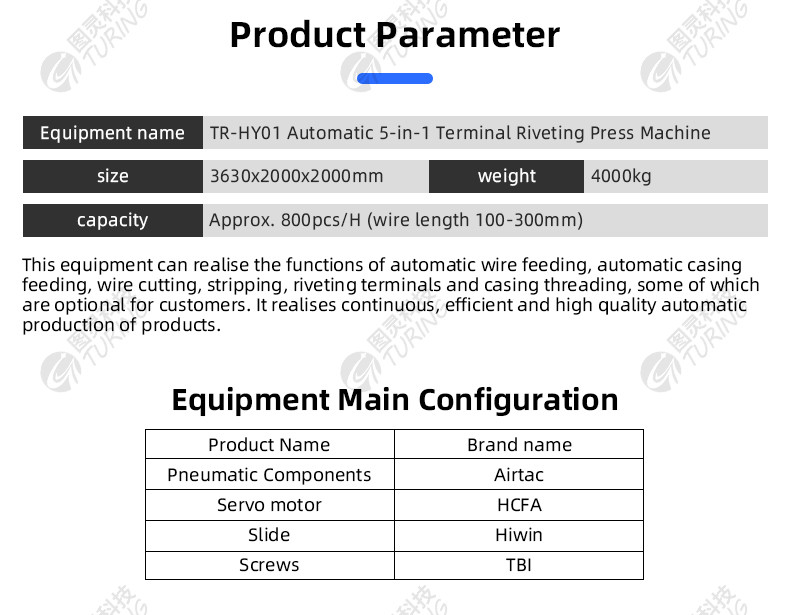

Paramtents

Power AC220V/50HZ,

Name Copper Tape Crimping Machine

Feature Stable Performance

Warranty 1year

Contact Lily 0086-13715588365

Packging & Delivery

Min Order1 piece

Briefing

Lily +8613715588365

Detailed

You need a product

You May Like

- Nearest port for product export

- Yantian, Huangpu, Shekou, Nansha

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, MoneyGram, Westem Union, Cash