Description of features

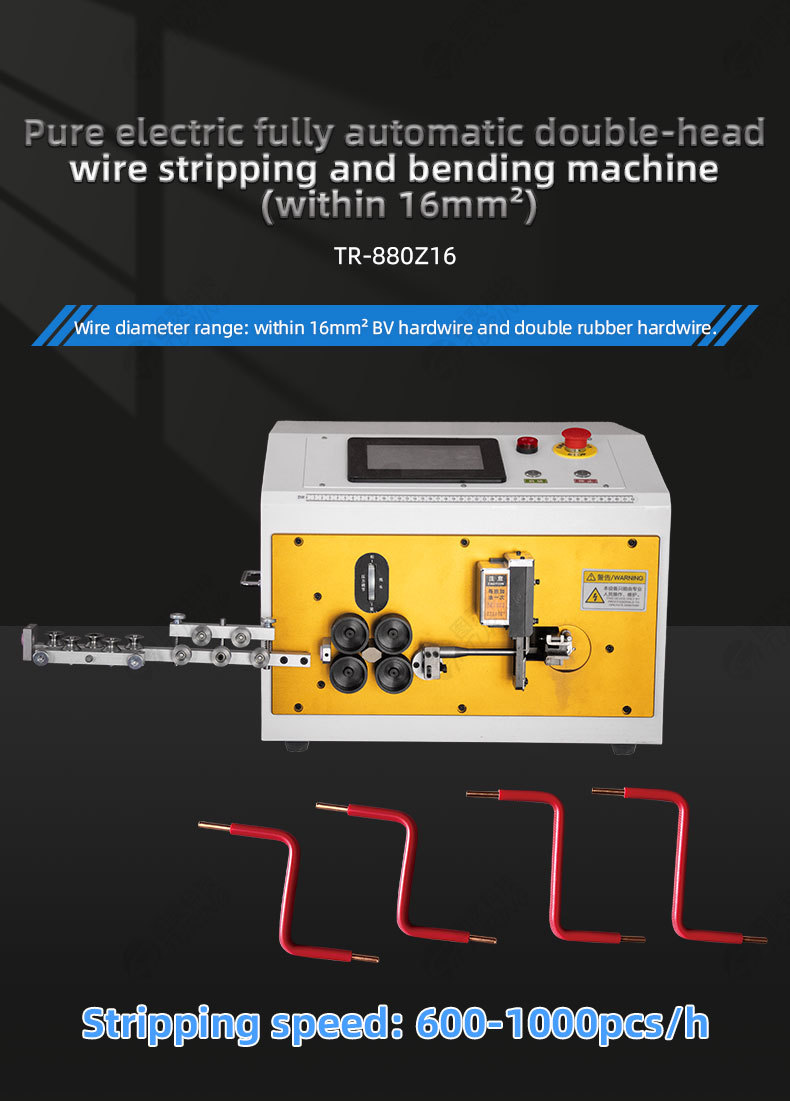

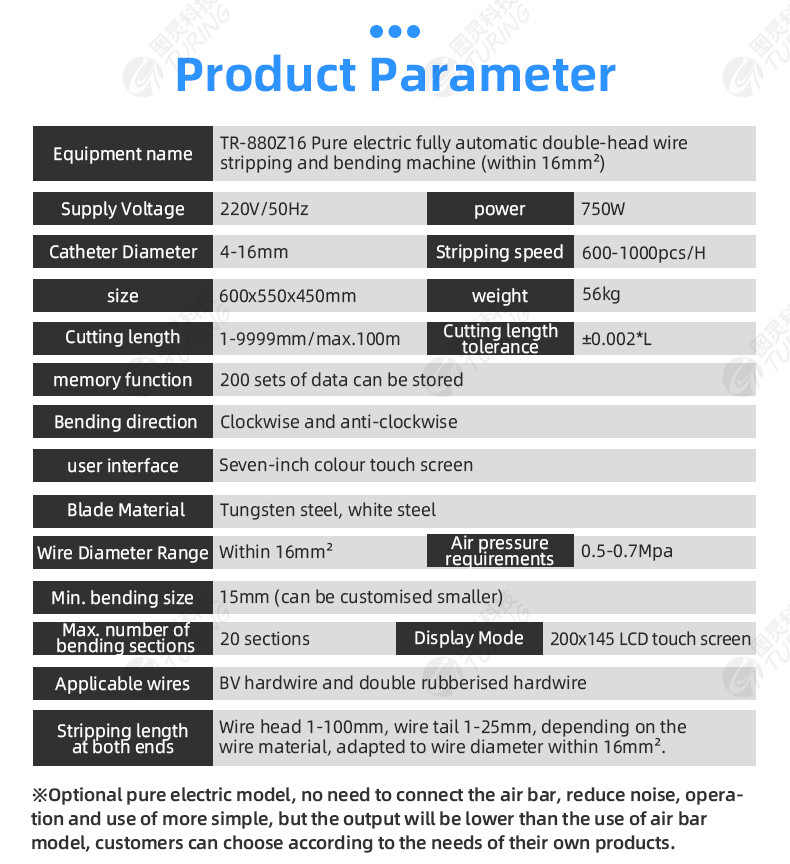

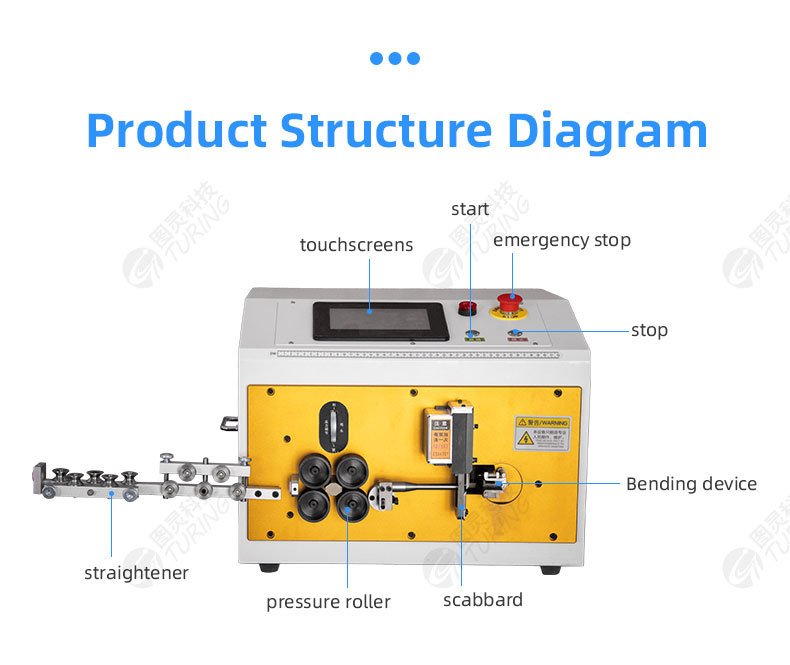

1.This is a fully automatic BV hard wire cutting, stripping and bending machine,which can process up to 16mm . The machine adopts 6 wire feeding wheels to feedthe wire, and the belt feeding device can also be ordered, thus increasing the con-tact area between the feeding wheels and the wire, which can prevent the wire fromslipping between the feeding wheels and provide strong peeling power.

2. Unique design of rear stripping clip makes this machine support wire tail strip-ping, after the wire is finished bending, the rear stripping clip will return the wire tothe knife holder for wire tail stripping. This is not the same as the principle of bend-ing and stripping machine without rear stripping clip function, although somemodels without rear stripping clip can also strip the end of the wire, but will be sub-ject to the length ofthe wire as well as the tightness of the wire skin limitations, andit is in the bending ofthe skin before stripping. This machine is after the completionof bending with the rear stripping clip for stripping, not affected by the length of thewire and the tightness of the wire skin.

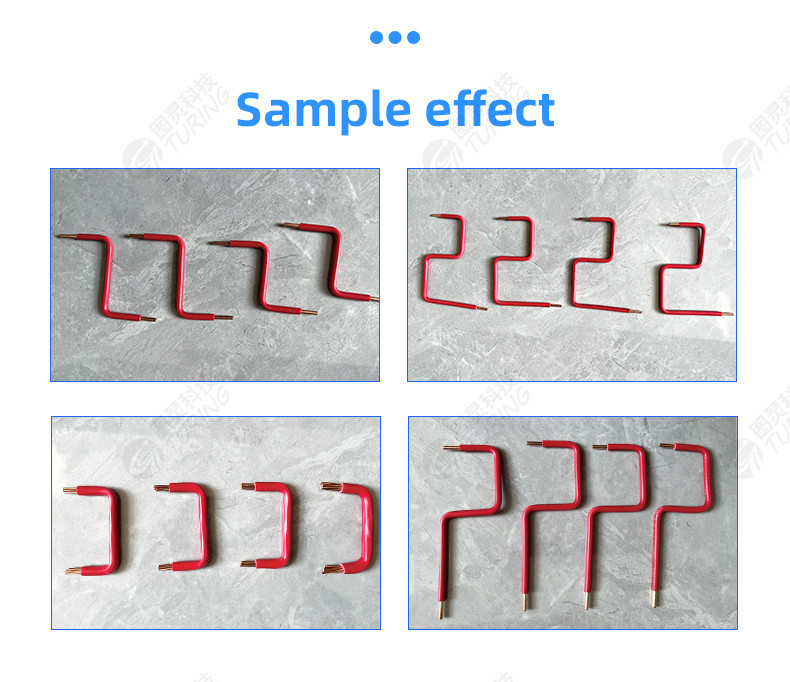

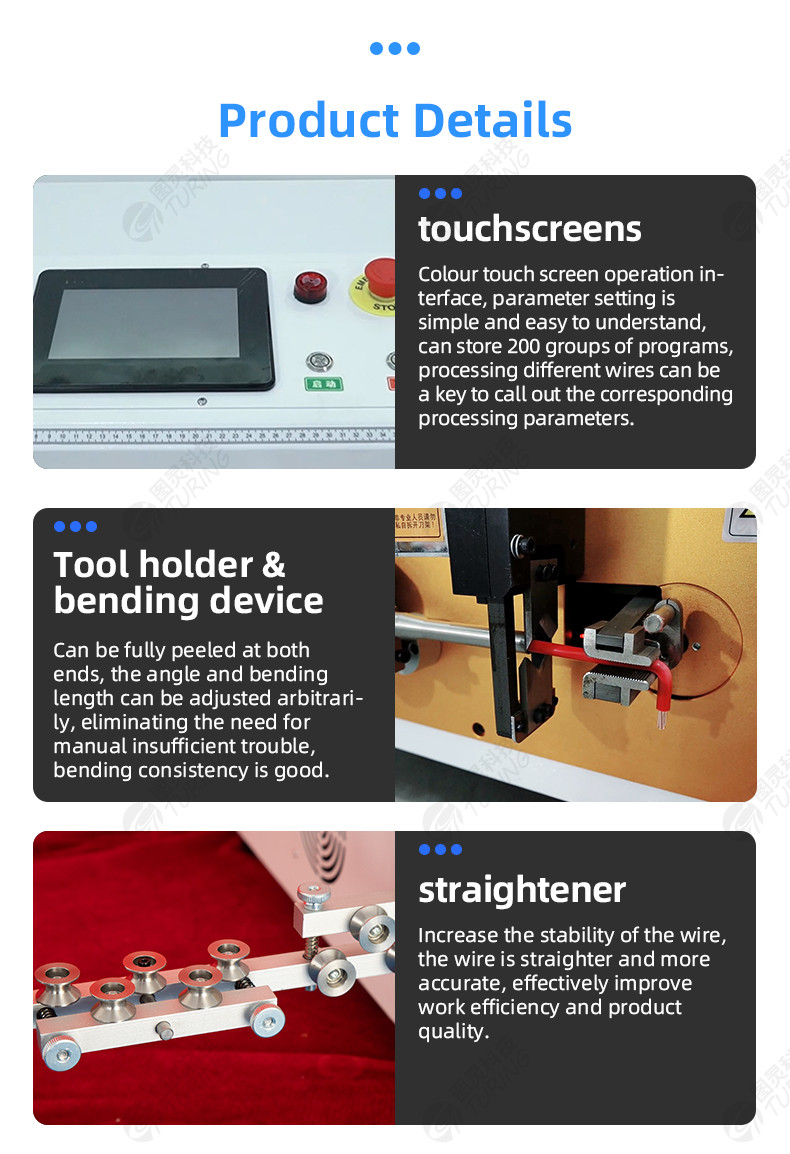

3. Colour touch screen operation interface, easy to understand the parameter set-tings. Stripping length, bending angle, length of each section and other parameterscan be set directly in the programme, the programme memory function can save upto 200 groups of programmes, processing different wires can be a key to call out thecorresponding processing parameters. in addition to optional computer industrialcontrol system, this system can also be optional printer, laser machine printingfunction. The biggest difference between this equipment is now on the market are ahead of skinning bending, keypad operation, my company's latest bending ma-chine. Brand touch-screen operation, the use of more intelligent, more complete,can be two full peeling, angle and bending length arbitrarily adjustable, eliminatingthe need for labour on the insufficiently annoying brain, the consistency of thebending is good, improve the efficiency of the work. is the majority ofthe productionof electronic control cabinets, meter boxes of the bending line, the contactor of thepositive and negative jumper necessary equipment.

-Can be retrofitted with a safety shield.

-Can be retrofitted with coding machine and laser printing machine, to achieve thetwo ends of the cut wire stripping, but also the two ends of the printing function.