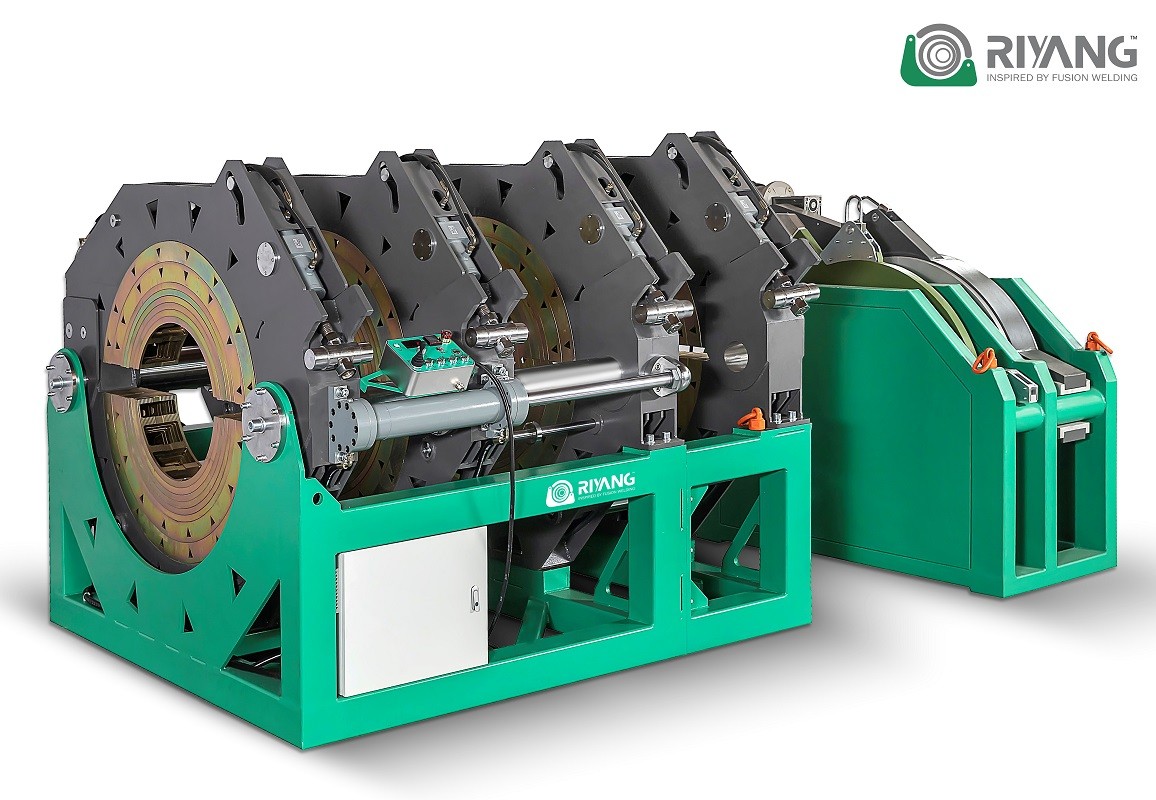

Hydraulic Butt Fusion Machine V1600 1200MM-1600MM (48'' IPS - 63'' IPS) | RIYANG Pipe Fusion Machine Manufacturer

group nameHydraulic Butt Fusion Machines

-

Min Order1 set

brand nameRIYANG

modelV1600

payment methodL/C, Western Union, T/T, Paypal

-

update timeFri, 08 Nov 2024 14:11:29 GMT

Paramtents

Certificate CE, ISO9001

Packing Material Plywood Box

MOQ 1set

Working Range in mm 1200mm - 1600mm

Working Range in Inch 48 - 63Inch

Working Pressure Range 0 - 160Bar

Welding Standard Applied ASTM F2620, ISO21307 SHP

Packging & Delivery

Min Order1 set

Briefing

Detailed

Hydraulic Butt Fusion Machine V1600 1200MM-1600MM (48''IPS - 63''IPS)

|

Product Details

|

|||

|

WELDING RANGE O.D.

|

1200MM - 1600MM

|

WELDING RANGE INCH

|

48" - 63" IPS

|

POWER SUPPLY | 380V±10%, 50/60HZ | TEMPERATURE RANGE | MAX. 280 ºC |

HEATER POWER | 42.0 KW | PACKING DIMENSION | 3540*2600*2300 MM |

|

TRIMMER POWER

|

7.5 KW

|

2340*1700*2000 MM

|

|

|

PUMP POWER

|

3.0 KW

|

/

|

|

WORKING PRESSURE RANGE | 0 - 160 BAR | GROSS WEIGHT | 7800KGS |

You need a product

You May Like

6YRS Riyang Fusion Manufacturing Limited

- Nearest port for product export

- Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDU

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union