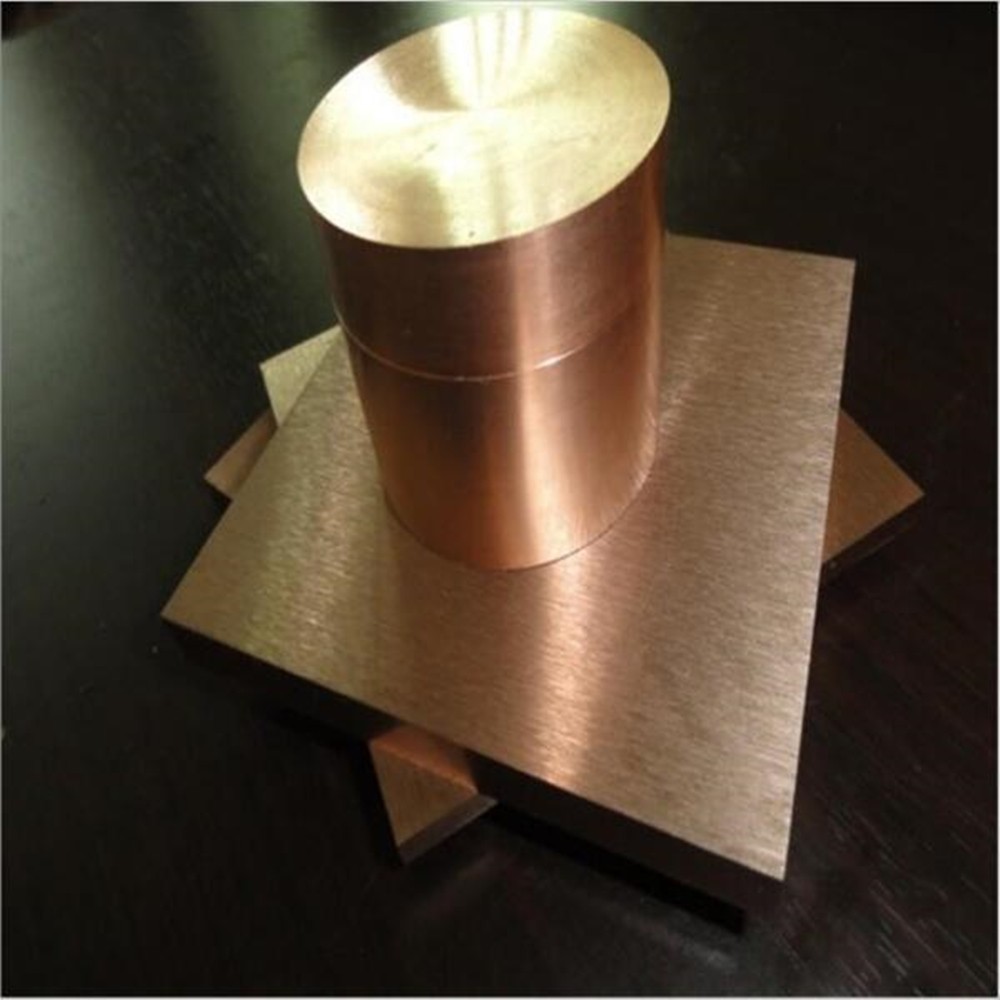

Wcu20 parts copper tungsten alloy properties with high strength used in electro machining electrodes

group nameTungsten Copper Alloys

-

Min Order1 kilogram

brand nameMMR Parts Processing | Custom Parts Manufacturing

payment methodL/C, D/A, D/P, Western Union

-

update timeTue, 05 Nov 2024 02:27:59 GMT

Paramtents

Grade WCu10,Wcu15,WCu20,WCu25,WCu30

Szie according to customer requirement

Density 14-17g/cm3

Technology powder metallurgy method

Surface bright surface,

Specifications Electronics, electric power, metallurgy

Packging & Delivery

Min Order1 kilogram

Briefing

Detailed

|

Grade

|

Density

|

conductivity

|

expansion coefficient

|

|

WCu7

|

17.5

|

150

|

5.5

|

|

WCu10

|

17.0

|

160

|

6.2

|

WCu15 | 16.2 | 170 | 6.9 |

Wcu20 | 15.4 | 180 | 7.4 |

Wcu25 | 14.7 | 200 | 8.0 |

Wcu30 | 14.1 | 220 | 8.8 |

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

You need a product

You May Like

- Nearest port for product export

- shanghai, tianjin, xi'an

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union, Cash