SWT-V500 200-500mm Welding Range Butt Fusion Welding Machine For PVC, PE, PP, PVDF | MM-Tech

group nameHydraulic Butt Fusion Welder

-

Min Order1 set

brand nameMM-Tech Thermoplastic Welding Equipment Manufactur

modelSWT-V500

payment methodL/C, T/T

-

update timeFri, 08 Nov 2024 18:46:46 GMT

Paramtents

Certificate CE, ISO9001

Packing Material 1 Set

MOQ Plywood Box

Packging & Delivery

Weight611.00kg / set

Min Order1 set

Briefing

Detailed

|

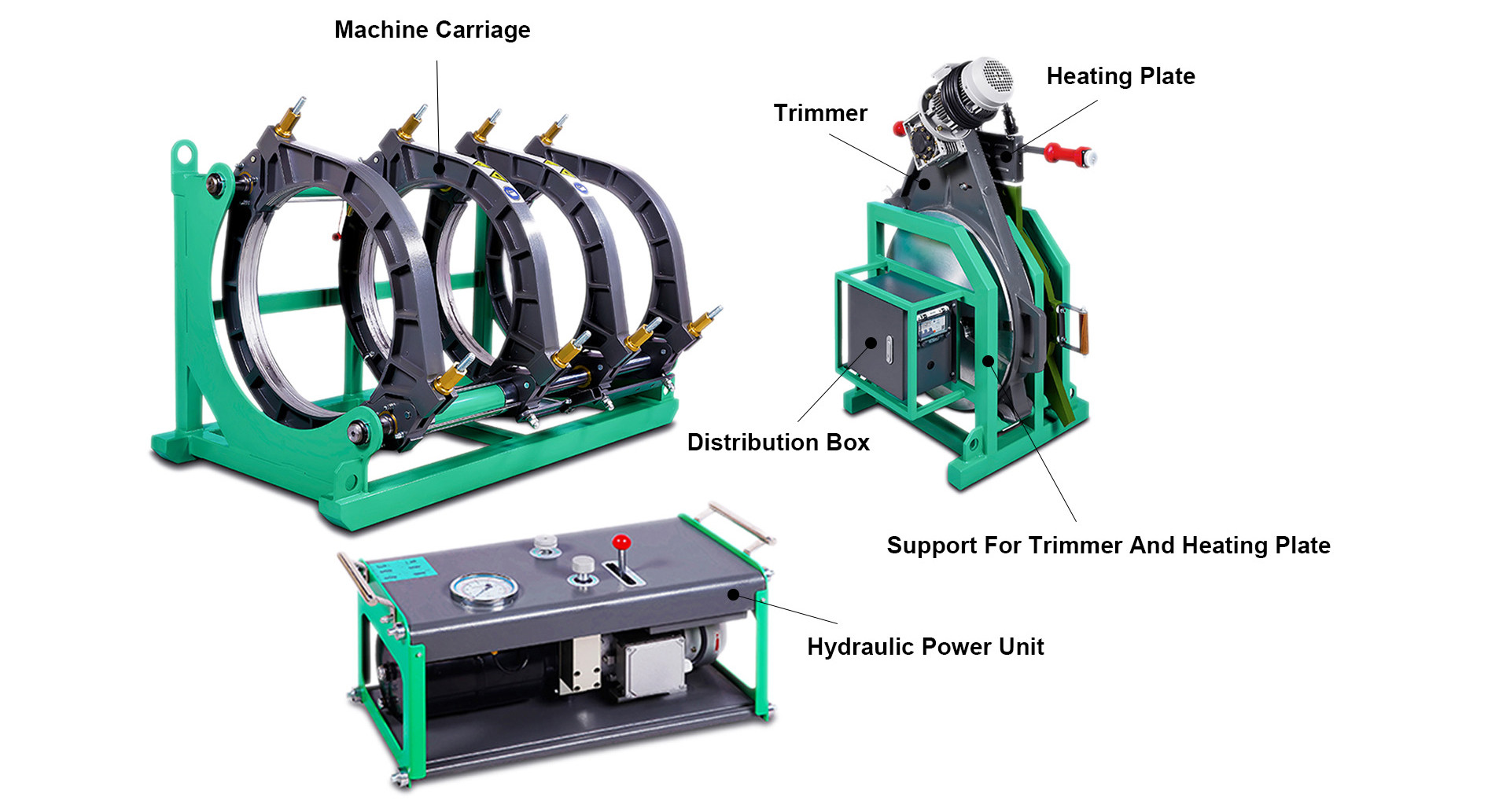

Hydraulic Butt Fusion Machine SWT-V500H 200MM-500MM (8" IPS -20'' IPS) Product Details |

|||

|

WELDING RANGE O.D.

|

200MM - 500MM

|

PISTON AREA

|

23.06cm²

|

|

POWER SUPPLY

|

380V±110%, 50/60HZ

|

TEMPERATURE RANGE

|

MAX. 320ºC

|

|

HEATER POWER

|

7.3KW

|

PACKING DIMENSION

|

1580*1000*960 MM

|

TRIMMER POWER | 1.5KW | 1030*680*1200 MM | |

PUMP POWER | 1.5KW | 800*350*400 MM | |

WORKING PRESSURE RANGE | 0 - 120 BAR | GROSS WEIGHT | 611KGS |

You need a product

You May Like

- Nearest port for product export

- Qingdao, Shanghai, Ningbo, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash, Escrow