electric 3 way ball valve for flow diverting, OEM/ODM Available

group name3 way electric ball valve

-

Min Order2 piece

brand nameFlomarvel motorized valve wholesale manufacturer

modelFH-MO-16

payment methodWestern Union, T/T, Paypal

-

update timeTue, 05 Nov 2024 11:53:40 GMT

Paramtents

Voltage of power supply 3-6V DC, 9-24V ADC, 110-230V AC

Valve material PVC, Brass, SS304 for option

Valve size 1/4''-1'' (DN8-DN25)

Thread BSP, NPT for option

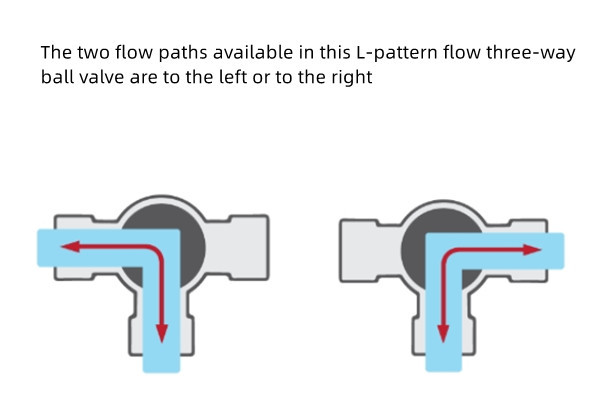

Flow pattern L type

Manual override Yes

Position indicator Yes

Cable length 35cm /13.8'' by default( customizable)

Wiring 2, 3, 5 wires for option

Packging & Delivery

Min Order2 piece

Briefing

Detailed

∎ Precision metal gear, high strength, reliable performance, long service life

∎ Multiple wiring for remote control and valve status feedback to intelligent control unit

∎ Floating sealing ball valve, no leakage

∎ Low power consumption, battery workable

∎ Flame retarded PC-ABS enclosure with compact, exquisite structure for small equipment

∎ IP 67 protection, applicable for humid environment

∎ With visual position indicator

∎ Various connectors customizable

∎ Manual override available for option

Motorized diverter valves offer a wide range of benefits in industrial applications, from increased productivity and cost savings to improved safety and reduced downtime. Their versatile functionality and durability make them an invaluable asset for companies aiming to unlock efficiency in today's competitive landscape.

By incorporating motorized diverter valves into their operations, companies can achieve seamless switching between different flow paths, allowing for greater control and flexibility in their processes. With the ability to redirect materials, reroute flow, or change the course of production swiftly and precisely, these valves save time, reduce operational costs, and optimize resource utilization.

Furthermore, motorized diverter valves contribute to improved safety measures by ensuring reliable redirection of materials and reducing the impact of downtime through quick and precise adjustments. Their applications span across various industries, including food and beverage, chemical, pharmaceutical, and oil and gas, where they enhance efficiency and productivity.

When selecting motorized diverter valves, factors such as flow capacity, durability, control options, and maintenance should be considered. Proper installation and regular maintenance are essential to ensure optimal performance and longevity.

Investing in motorized diverter valves is a strategic decision that can lead to enhanced efficiency, increased productivity, and improved overall performance in industrial applications. With their robust construction, precise control, and versatile functionality, these valves are undoubtedly a game-changer for industries striving to stay ahead in today's competitive landscape.

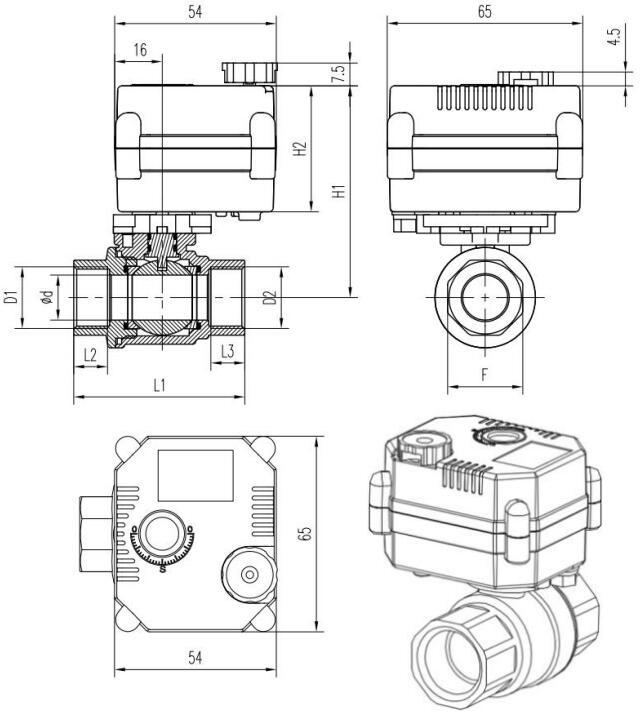

D1/D2 | DN | φd | L1 | L2/L3 |

F

|

H1

|

H2

|

Weight (KG)

|

1/4'' | DN8 | 8 | 45 | 10 |

21

|

68

|

42

|

0.25

|

1/2'' | DN15 | 15 | 57 | 11 | 25 | 71 | 42 | 0.31 |

3/4'' | DN20 | 20 | 63 | 12 |

31

|

74

|

42

|

0.40

|

1'' | DN25 | 25 | 73 | 16 |

37

|

77

|

42

|

0.51

|

Series | Torque | Operating time | Working voltage |

Working current

|

Max. power

|

Max. pressure

|

FH | 2.5 N.M | <5S | 3-6V DC, 9-24V ADC, 110-230V AC |

<100 mA

|

5W

|

1.0 Mpa

|

Medium temperature | Ambient temperature | Humidity | Enclosure |

Service life

|

Wiring |

|

0-100℃/32-212℉ | -20-45℃/-4 -113℉ | 95% | IP67 |

50,000 - 80,000 times

|

OP01, OP02, OP03, OP04, OP05 optional, customization available |

You need a product

You May Like

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDU, Express Delivery

- Acceptable payment methods

- T/T, Westem Union