High precision round pipe dies for tube mill machines | tube roller for welded pipe production line

group namePipe Mould & Roller Sets

-

Min Order1 set

brand nameYuanxinya Stainless Steel Pipe Forming Machines

payment methodL/C, Western Union, MoneyGram, T/T, Paypal

-

update timeTue, 05 Nov 2024 11:36:14 GMT

Paramtents

Application Installed on the pipe mill to produce pipes

Mould Material Cr12MoV/SKD11/D2

Shaping Mode Compression Mould

Pipe Types Round, Square, Irregular shape

Round Pipe Spe. Φ5-Φ630

Square pipe range F10x10~F500x500

Rectangle pipe range F10x20~F300x600

Hardness range HRC63-65

Tolerance range Roundness ±0.05

Tolerance range Flatness ±0.04

Warranty Period 1 year

Life Span 10 years

Mold maintenance Avaliable

Customized service Avaliable

Packging & Delivery

Min Order1 set

Briefing

Detailed

|

Pipe type

|

Specification(mm)

|

Tolerance Range

|

Hardness

|

|||

|

Round pipe

|

ф5~ф630

|

Roundness+/-0.05

|

HRC63~65

|

|||

|

Square pipe

|

F10×10~F500×500

|

Flatness+/-0.04

|

HRC63~65

|

|||

|

Rectangle pipe

|

F10×20~F300×600

|

Flatness+/-0.04

|

HRC63~65

|

|||

Othe profile | Flat pipes, Elliptical pipes, Plum blossom pipes, Fan-shaped pipes, Polygonal pipes, Single and Double grooved pipes. | |||||

|

Material

|

Varieties

|

||

|

Cr12Mov

|

Dongbei Special Steel Co., Ltd.

|

Daye Special Steel Co.,Ltd.

|

Export Standard From Big Private Company

|

|

SKD11

|

Dongbei Special Steel Co., Ltd.

|

Daye Special Steel Co.,Ltd.

|

Taiwan / Janpan

|

|

D2

|

Daye Special Steel Co.,Ltd.

|

Taiwan

|

|

|

No.

|

Treatment method

|

Roller HRC

|

||||||

|

1

|

Vacuum Heat Treatment

|

HRC61~63

|

||||||

|

2

|

Black Quenching Heat Treatment

|

HRC61~63

|

||||||

3 | Vacuum Gas Quenching and Subzero Heat Treatment | HRC63~65 | ||||||

|

Packaging Details |

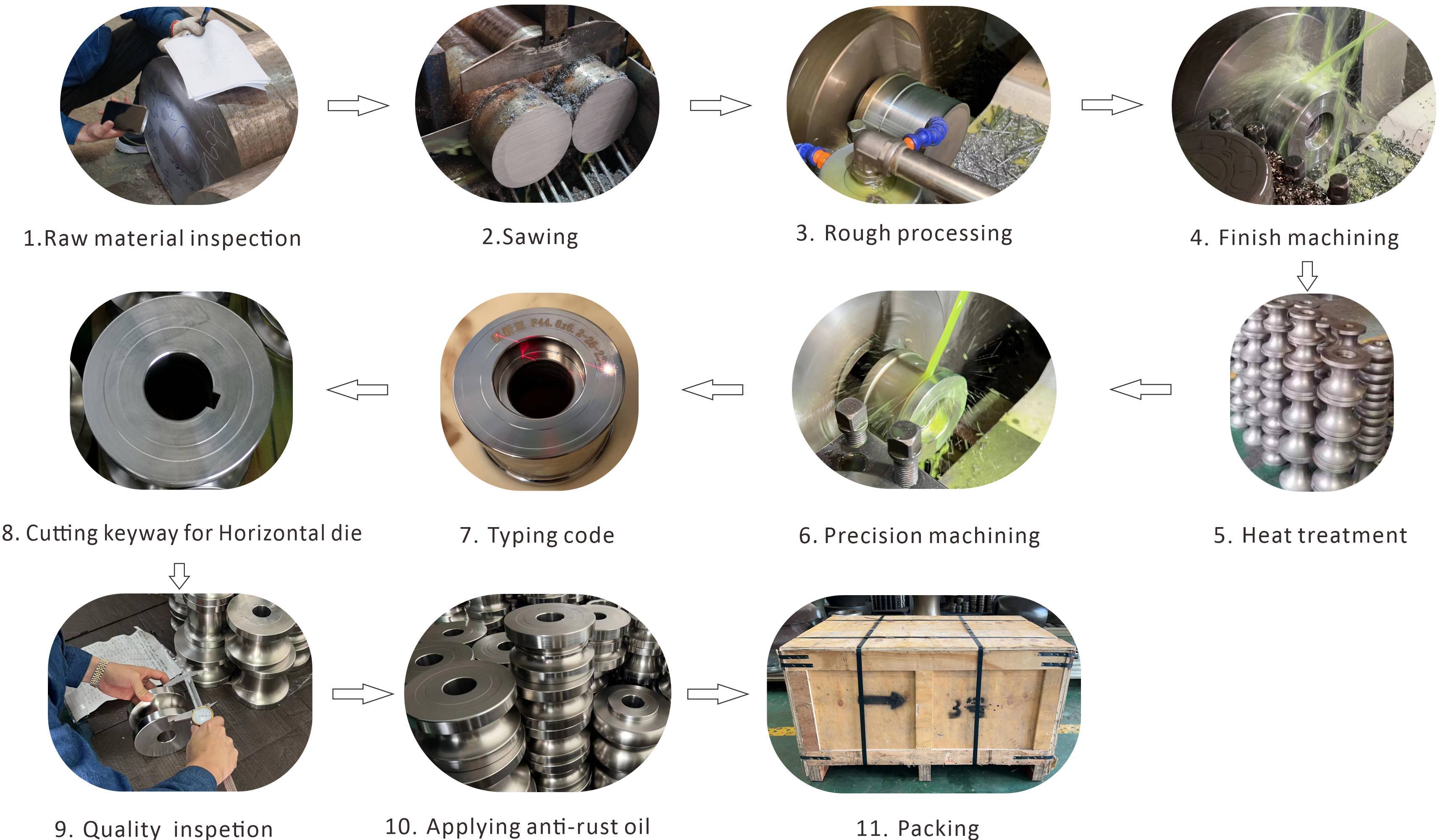

1. Apply anti-rust oil on the mold.

|

||||

|

2. Packed in fumigation wooden cases, lined with paper and cloth.

|

|||||

|

3. Wrapped with protective film.

|

|||||

|

Lead time

|

5~30 days, depend on the type and quantity of the roller

|

||||

Shippment terms | FOB Foshan/Guangzhou; CIF, DDU,DDP for option. | ||||

You need a product

Related Searches

You May Like

6YRS Foshan Yuanxinya Machinery Equipment Co., Ltd.

- Nearest port for product export

- FoShan, GunagZhou, ShenZhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, MoneyGram