CNC Mandrel Tube Bending Machines For Stainless Steel Exhausts System 3 1/2 inches

group nameMandrel Tube Benders

-

Min Order1 set

brand nameBossray CNC Tube bender and Lasertube Manufacturer

modelSB-89CNC-H

payment methodT/T

-

update timeTue, 05 Nov 2024 11:47:40 GMT

Paramtents

Bending capability OD×WT Φ90×3.0 mm

Bending speed Max. 100°/sec

Feeding speed 1000 mm/sec

Feeding accuracy ±0.1 mm

Rotating speed 180°/sec

Rotating accuracy ±0.1°

Voltage 220V, 380V, 415V, 440V, 480V, 600V

Mandrel bending Ball Mandrel

Wiper die Brass Wiper

Machine cover Safety Cover

Packging & Delivery

Weight4000.00kg / set

Min Order1 set

Briefing

Detailed

|

Model |

SB-89CNC-H |

|||

|

Bending capability OD×WT (carbon steel):

|

Φ88.9×4.0 mm |

|||

|

Bending radius: |

320mm |

|||

|

Bending angle |

0~190° |

|||

Max bending length with mandrel: | 3500mm | |||

Bending speed: | Max. 100°/sec | |||

Bending accuracy: | ±0.1° | |||

Feeding speed: | 1000 mm/sec | |||

Feeding accuracy: | ±0.1 mm | |||

Rotating speed: | 180°/sec | |||

Rotating accuracy: | ±0.1° | |||

Tools stack: | 1 or multiple | |||

Bending: | Electric Servomotor or Hydraulic | |||

Feeding/Booster: | Electric Servomotor | |||

Rotating: | Electric Servomotor | |||

Work head shift (horizontal): | Electric Servomotor option | |||

Work head shift (vertical): | Hydraulic /Electric Servomotor option | |||

System hydraulic pressure: | 14 MPa | |||

Packing size refer: | 5200×1150×1450mm | |||

Weight refer: | 4000kgs | |||

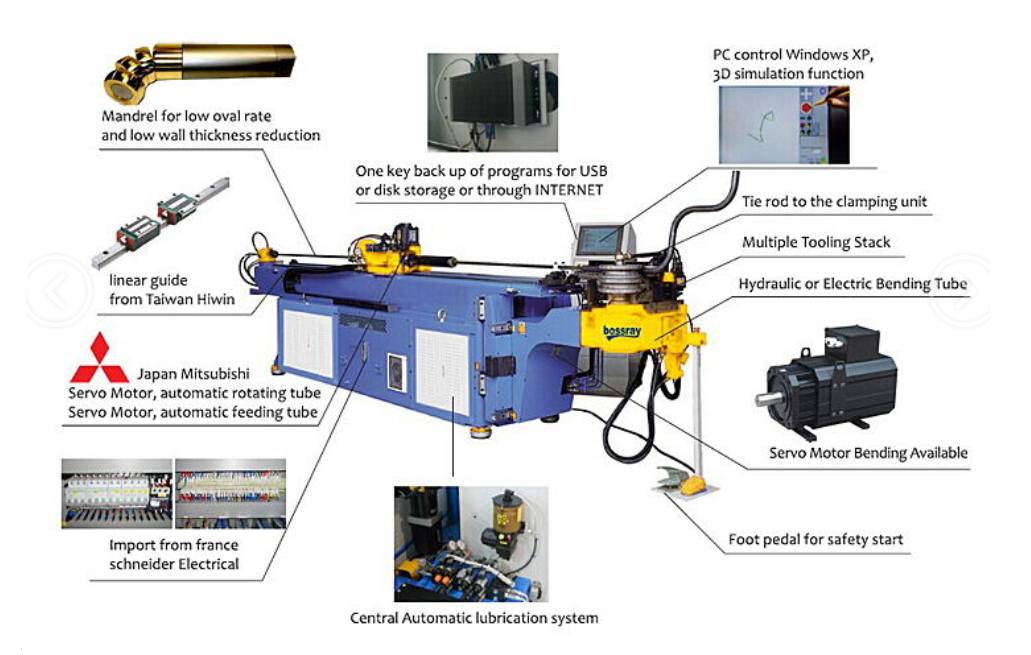

- 1Bend-arm (C-axis) by Hydraulic / Servomotor

- 2Clamp die by hydraulic or servomotor; pressure die by hydraulic or servomotor.

- 3Carriage (Y-axis) by servomotor.

- 4With rear booster is driven by a servo motor.

- 5Collets (B-axis): rotation by servo motor, grip by hydraulic or servomotor.

- 6 With the roll bending function (PUSH BENDING), can make a big radius by rolling.

- 7Tooling shift: motion up-down by hydraulic or servomotor with brake; left-right by servomotor.

- 8PDA (pressure die assist): by hydraulic or servomotor.

- 9Automatic moving parts lubrication systems.

- 10Standing pedestal, serves emergency stop, double-hand startup, and remote control.

- 11Industrial PC (windows system) assorted with touch screen display, 3D preview, remote control, 3D bending simulation, and collision prevention.

- 1Multi radius

- 2Left and right direction bending

- 3Punching device

- 4Cutting device

- 5Safety fence

- 6Safety mat or Light curtain protection

- 7Bend 1.0*D radius or more tight radius

- 8Fan / Water / Oil cooling system

- 9Robot loading and unloading systems

- 10Safe blanket / Infrared alarm device

- 11SIEMENS 3D convert

- 12Electric power supply transformer

- 13Quick tooling change

- 14Special tooling design and brass mandrel

You need a product

You May Like

6YRS BOSSRAY MACHINERY

- Nearest port for product export

- Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Credit Card, Westem Union