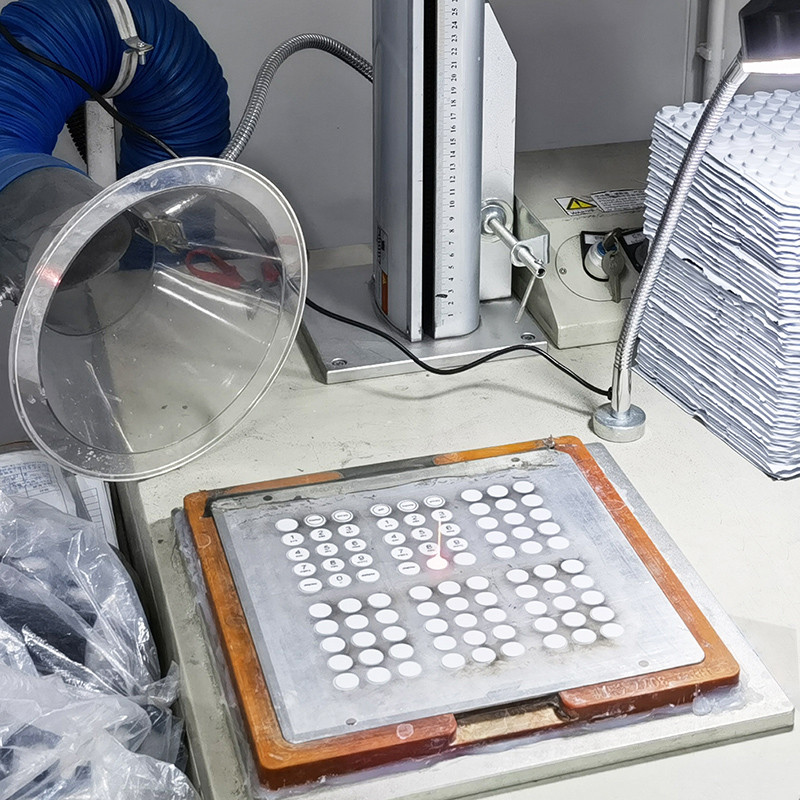

FromRubber Custom Silicone Rubber Keypad For Air and Water Quality Detector

group nameMeter Instrument Keypad

-

Min Order1 piece

brand nameFromRubber Silicone & Plastic OEM Manufacturer

payment methodT/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash

-

update timeFri, 08 Nov 2024 21:45:15 GMT

Paramtents

Design Follow 3D Drawing Or Physical Object

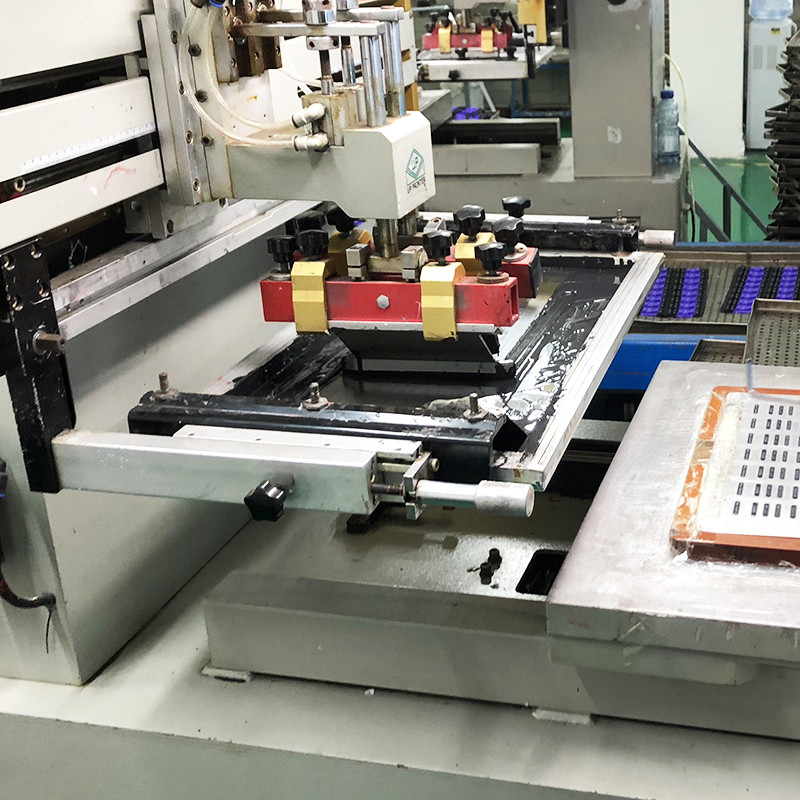

Printing Silk Screen Printing

Feature Clear and Bright Characters

MOQ 1000pcs

Application Air and Water Quality Detector

Packging & Delivery

Min Order1 piece

Briefing

Detailed

You need a product

You May Like

- Nearest port for product export

- FOB shenzhen

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FCA, DDP, Express Delivery

- Acceptable payment methods

- T/T, D/P D/A, Credit Card, PayPal, Westem Union, Cash